Composite nano fiber endless tow preparing apparatus and its preparing method

A composite nanofiber and nanofiber technology, applied in fiber processing, rayon manufacturing, conjugated rayon, etc., can solve the problems of fiber loss and instability, achieve thick tow, easy operation, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

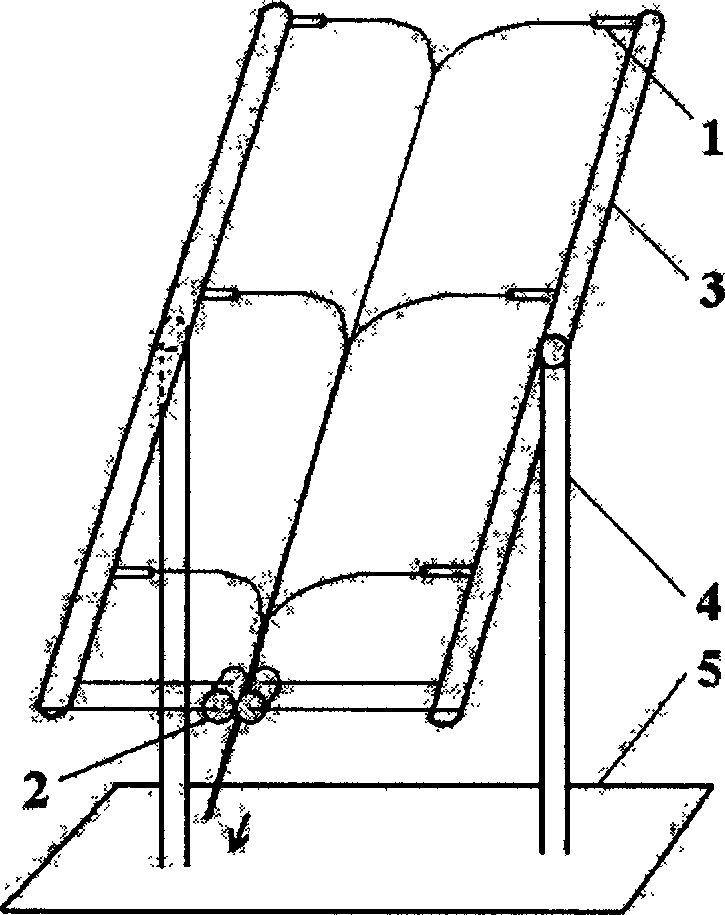

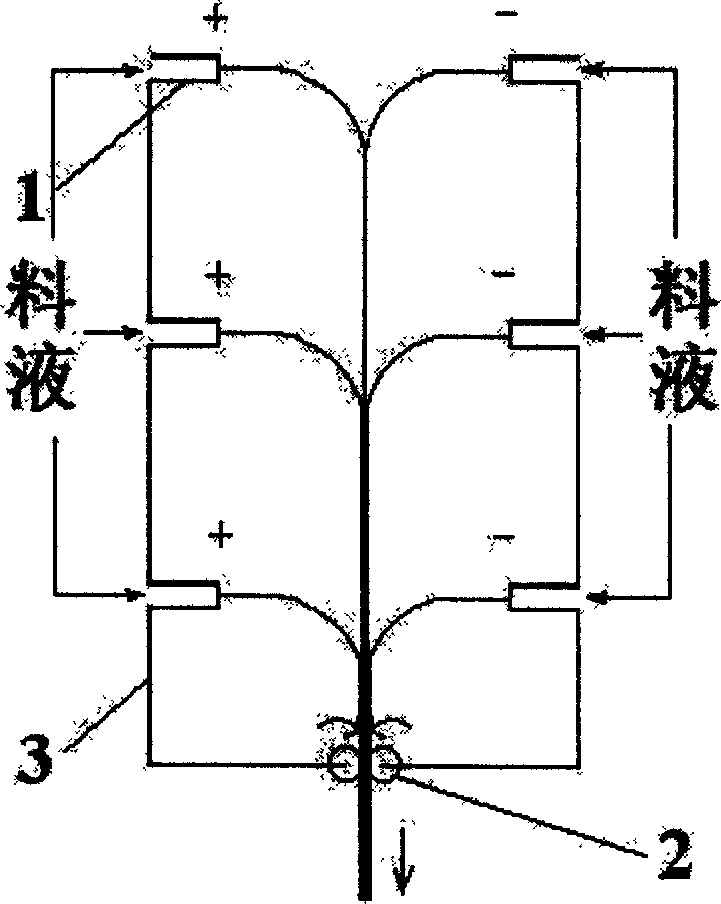

[0048] 10g of poly-L-lactic acid PLLA (viscosity average molecular weight 100,000) was dissolved in a mixed solvent of 50ml of acetone and 50ml of N,N-dimethylformamide to prepare solution No. 1, lactide-glycolide copolymer PLGA (which Mass composition: lactide 50%, glycolide 50%, viscosity average molecular weight 100,000) 15g is dissolved in a mixed solvent of 50ml acetone and 50ml N,N-dimethylformamide to prepare solution No. 2, and solution No. 1 is transported Give 3 electrospinning nozzles in the same row on the bracket, and deliver the No. 2 solution to another row of 3 electrospinning nozzles on the bracket. The nozzles are 40cm apart. A 90° angle is formed between the plane where the bracket is located and the fixing rod. A DC high voltage of opposite polarity ±20 kV was applied to the two rows of electrospinning nozzles with opposite nozzles, and the inner diameter of the electrospinning nozzles was 0.5 mm. The speed at which the godet pair drew the filament bundle...

Embodiment 2

[0050] Poly-L-lactic acid PLLA (viscosity average molecular weight 100,000) 10g was dissolved in a mixed solvent of 50ml acetone and 50ml N,N-dimethylformamide to prepare solution No. 1, polycaprolactone PCL (molecular weight 90,000) 10g dissolved Prepare solution No. 2 in 100ml N,N-dimethylformamide, and deliver No. 1 solution to the same row of 4 electrospinning nozzles on the stent, and deliver No. 2 solution to another row of 4 electrospinning nozzles on the stent. The distance between adjacent electrospinning nozzles in the same row above is 15 cm, and the distance between electrospinning nozzles in two rows with opposite nozzles is 40 cm. A 90° angle is formed between the plane where the bracket is located and the fixing rod. A DC high voltage of opposite polarity ±20 kV was applied to the two rows of electrospinning nozzles with opposite nozzles, and the inner diameter of the electrospinning nozzles was 0.5 mm. The speed at which the godet pair drew the filament bundle...

Embodiment 3

[0052] Poly-L-lactic acid PLLA (viscosity average molecular weight 100,000) 10g was dissolved in a mixed solvent of 50ml acetone and 50ml N,N-dimethylformamide to prepare solution No. 1, Zein ZEIN (molecular weight 35,000) 35g was dissolved in 100ml The solution No. 2 is prepared in an ethanol aqueous solution (the volume ratio of ethanol / water is 80 / 20), and the No. 1 solution is delivered to the same row of 3 electrospinning nozzles on the support. The inner diameter of the electrospinning nozzle is 0.8 mm, and the No. There are 3 electrospinning nozzles in another row on the support. The inner diameter of the electrospinning nozzles is 1.2 mm. The distance between adjacent electrospinning nozzles in the same row on the support is 15 cm. A 90° angle is formed between the plane where the bracket is located and the fixing rod. Apply DC high voltages of opposite polarity ±25kV to the two rows of electrospinning nozzles with opposite nozzles respectively. The speed at which the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com