Preparation method of efficient crude oil desalting demulsifier

A demulsifier and crude oil technology, applied in the field of preparation of crude oil desalination demulsifier, can solve the problems of metal cation removal, weak binding ability, etc., and achieve the effects of high molecular weight, good use safety and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

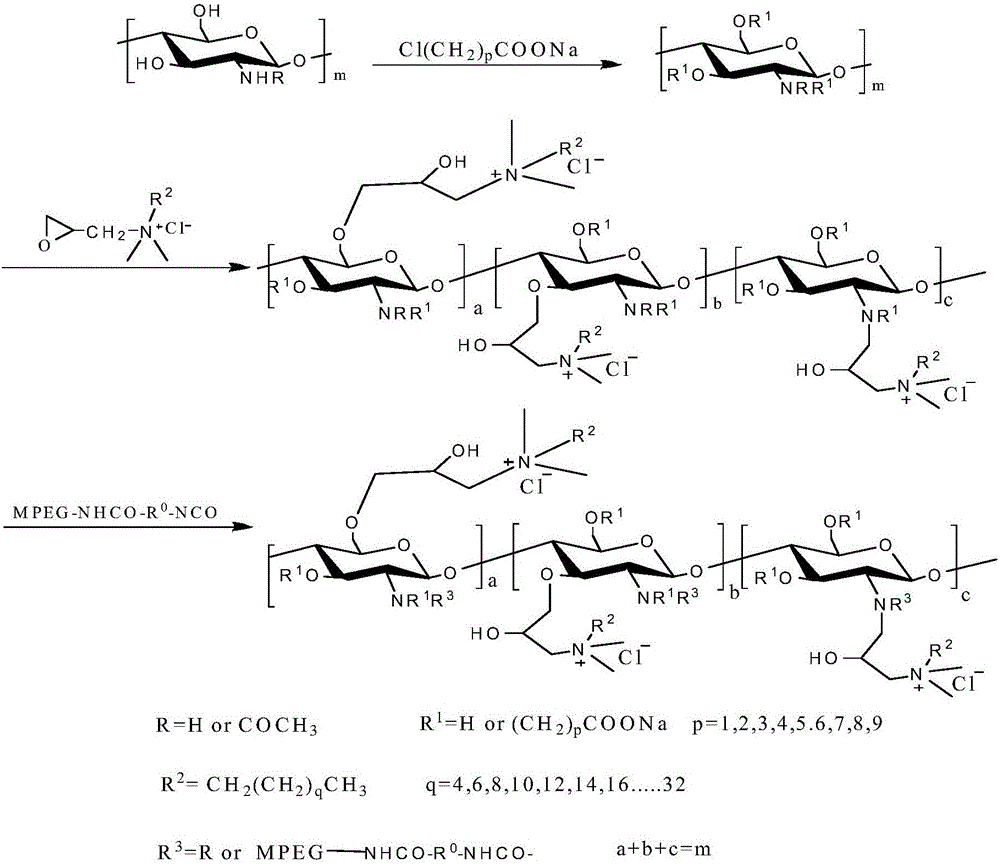

[0043] A kind of preparation of efficient crude oil desalting demulsifier, its synthesis comprises the steps:

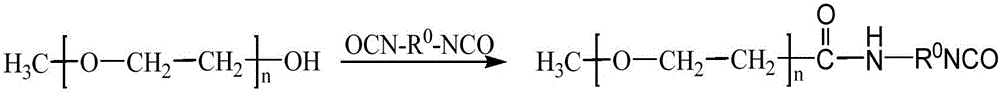

[0044] (1) Isocyanate modification of polyethylene glycol monomethyl ether terminal hydroxyl group: Add 1.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=350) into 50 mL N,N dimethylformamide, heat to 55°C, magnetic stirring to fully dissolve the solution, cool the solution to 30°C, and then dissolve 0.125g (5mmol) diphenylmethane diisocyanate in 10mL N,N dimethylformamide, and add dropwise through the dropping funnel To the polyethylene glycol monomethyl ether N,N dimethylformamide solution, the dropping process is controlled within 30 minutes. After the dropwise addition, the temperature was raised to 60° C., and the reaction was performed at a constant temperature for 2 hours. After the reaction was completed, it was distilled under reduced pressure, dialyzed for 3 days, and freeze-dried to obtain isocyanated polyethylene glycol monomethyl ether.

[00...

Embodiment 2

[0050] A kind of preparation of efficient crude oil desalting demulsifier, its synthesis comprises the steps:

[0051] (1) Isocyanate modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: Add 3.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=750) into 50 mL of N,N dimethylacetamide, heat to 60°C, magnetic stirring to fully dissolve the solution, cool the solution to 35°C, then dissolve 0.174g (10mmol) toluene diisocyanate in 10mL of N,N dimethylacetamide, and add dropwise to polyethylene diisocyanate through the dropping funnel Alcohol monomethyl ether N,N dimethylacetamide solution, the dropping process is controlled within 30min. After the dropwise addition, the temperature was raised to 50° C., and the reaction was performed at a constant temperature for 6 hours. After the reaction was completed, it was distilled under reduced pressure, dialyzed for 4 days, and freeze-dried to obtain isocyanated polyethylene glycol monomethyl ether.

...

Embodiment 3

[0057] A kind of preparation of efficient crude oil desalting demulsifier, its synthesis comprises the steps:

[0058] (1) Isocyanate modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: Add 5 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=1000) into 50 mL of acetone, heat to 60 ° C, and magnetically stir to make it Fully dissolve, cool the solution to 40°C, then dissolve 0.223g (10mmol) isophorone diisocyanate in 10mL of acetone, and add it dropwise to the polyethylene glycol monomethyl ether acetone solution through the dropping funnel, dropwise The process is controlled at 30min. The temperature was raised to 55°C, and the reaction was carried out at constant temperature for 4h. After the reaction was completed, it was distilled under reduced pressure, dialyzed for 3 days, and freeze-dried to obtain isocyanated polyethylene glycol monomethyl ether.

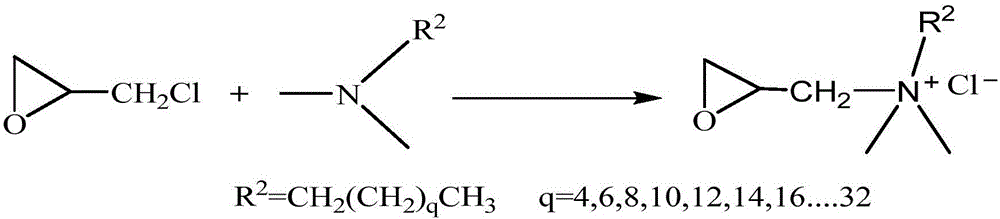

[0059] (2) Preparation of glycidyl dimethyl cetyl ammonium chloride: add 2.69g cetyl d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com