Electroplating solution and method for forming color plating

A technology of electroplating solution and content, applied in the direction of electrolytic inorganic material plating, coating, electrolytic coating, etc., can solve complex problems and achieve the effect of simple operation, firm coloring and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

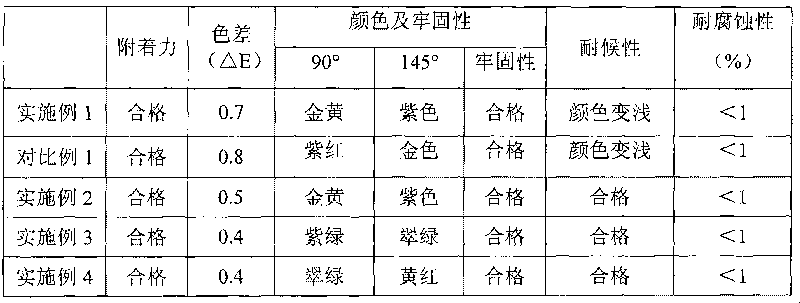

Examples

Embodiment 1

[0035] Work piece: choose stainless steel with type 314 (100×50×10mm)

[0036] 1. Chemical degreasing

[0037] The workpiece was immersed in the degreasing liquid at 60°C for 6 minutes. The degreasing liquid is an aqueous solution containing 80 g / L of sodium hydroxide, 30 g / L of sodium carbonate, 12 g / L of sodium silicate and 30 g / L of trisodium phosphate. Then remove the workpiece and wash it with water.

[0038] 2. Pickling activation

[0039] Soak the substrate after the above degreasing in the pickling solution at room temperature for 2 minutes. The pickling solution is an aqueous solution obtained by adding 36% hydrochloric acid to 50 ml / L. Then remove the workpiece and wash it with water.

[0040] 3. Electroplating color coating

[0041] The above-mentioned activated workpiece is used as the cathode and immersed in the electroplating solution at 50°C, and the lead-tin alloy is used as the anode. The pH value of the electroplating solution is 6.6, the voltage is 2V,...

Embodiment 2

[0060] Workpiece: select the same workpiece as in Example 1

[0061] The workpiece was electroplated according to the method described in Example 1, except that, after the workpiece was electroplated, the electroplated workpiece was immersed in hot water at 70° C. for 5 minutes for hot water washing.

Embodiment 3

[0063] Workpiece: Zirconium alloy of Zr-2 type (100×50×3mm)

[0064] 1. Chemical degreasing and pickling activation

[0065] Chemical degreasing and pickling activation were performed in the same manner as described in Example 1.

[0066] 2. Electroplating color coating

[0067] The above-mentioned activated workpiece is used as the cathode and immersed in the electroplating solution at 40°C, with stainless steel as the anode, the pH value of the electroplating solution is 5.0, the voltage is 1.5V, and the current density is 0.3A / dm 2 Electroplate the workpiece for 10 minutes under certain conditions, and immerse the above-mentioned electroplated workpiece in hot water at 60°C for 2 minutes for hot water washing.

[0068] The electroplating solution is an aqueous solution containing 30 g / L of lactic acid, 50 g / L of boric acid, 15 g / l of molybdic acid, 60 g / l of phosphoric acid, 1 g / l of allylsulfonic acid and 3 g / l of 3-ethylhexyl stearate. Then remove the workpiece and was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com