Hydraulic hammer rod type impact drilling tool

A technology of percussion drilling and hydraulic hammer, which is used in drilling equipment, driving devices for drilling in wellbore, and earth-moving drilling, etc., can solve the problems of short life of hydraulic impactor, inability to adjust the impact load, poor stability, etc. To achieve the effect of increasing the rate of penetration of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

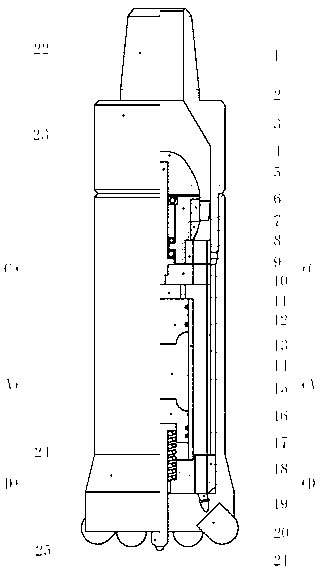

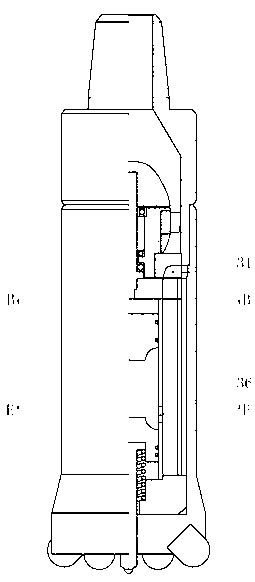

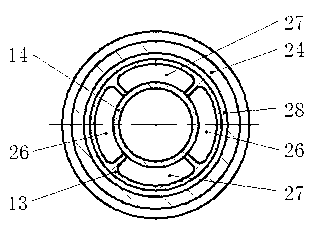

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Such as Figure 1-7 As shown, a hydraulic hammer rod impact drilling tool is mainly composed of a turbine drive device, a rotary valve flow distribution mechanism, an impact device, an end cap 1, a hammer 12, an outer cylinder 13, an inner cylinder 14, a sealing ring 17, and a flow guide Disc 18, housing 23 and drill bit 24 are formed. It is characterized in that: the turbine driving device includes a fixed shaft 2, an upper deep groove ball bearing 3, a turbine disc 4, a turbine blade 5, a pressure plate 6, a lower deep groove ball bearing 7, a thrust bearing 8, the fixed shaft 2 and the turbine The upper deep groove ball bearing 3, the lower deep groove ball bearing 7 and the thrust bearing 8 are arranged between the disks 4, and the upper deep groove ball bearing 3 and the lower deep groove ball bearing 7 are respectively positioned by the upper sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com