Preparation method of glycerin trinitrate

A technology of nitroglycerin and fuming nitric acid, which is applied in the chemical industry, can solve the problems of accelerating the decomposition of nitroglycerin, failing to meet quality requirements, and exceeding the standard of nitroglycerin substances, and achieve the effects of reducing losses, avoiding dissolution and decomposition, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

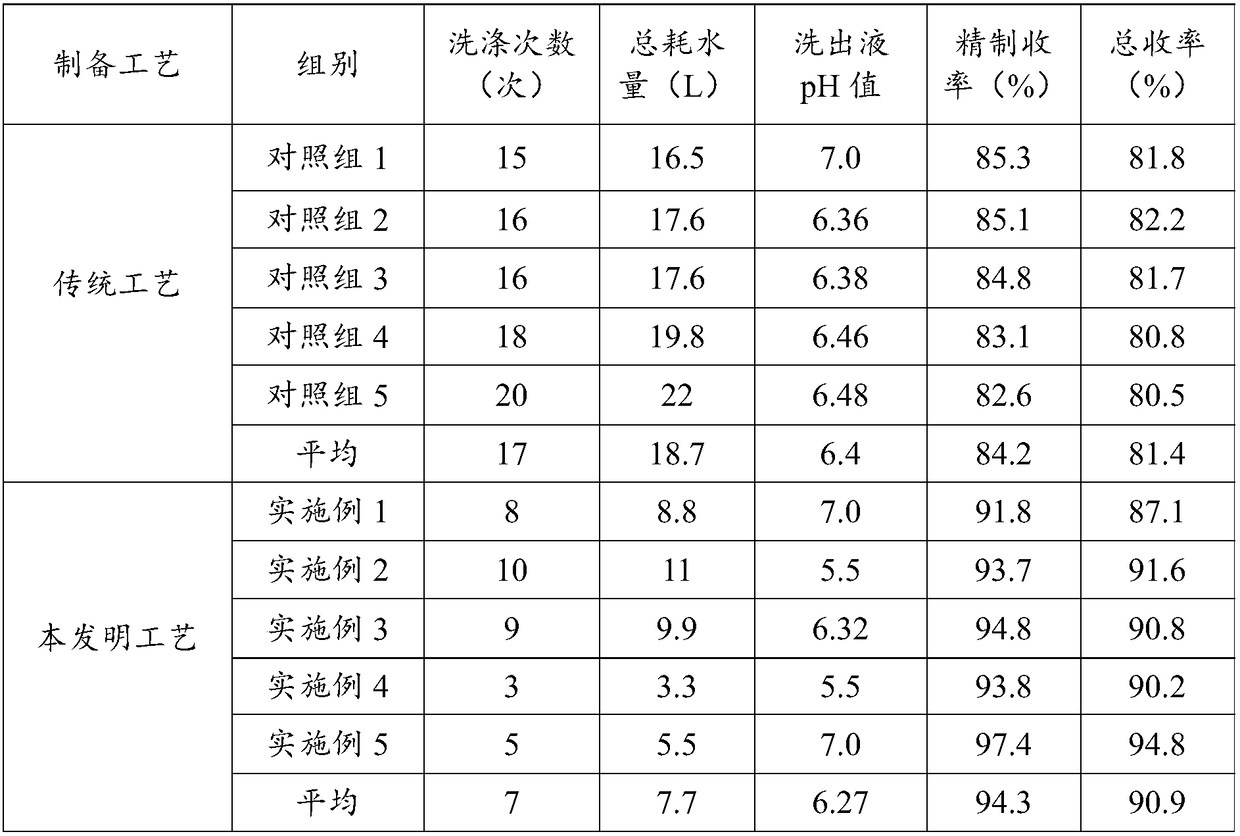

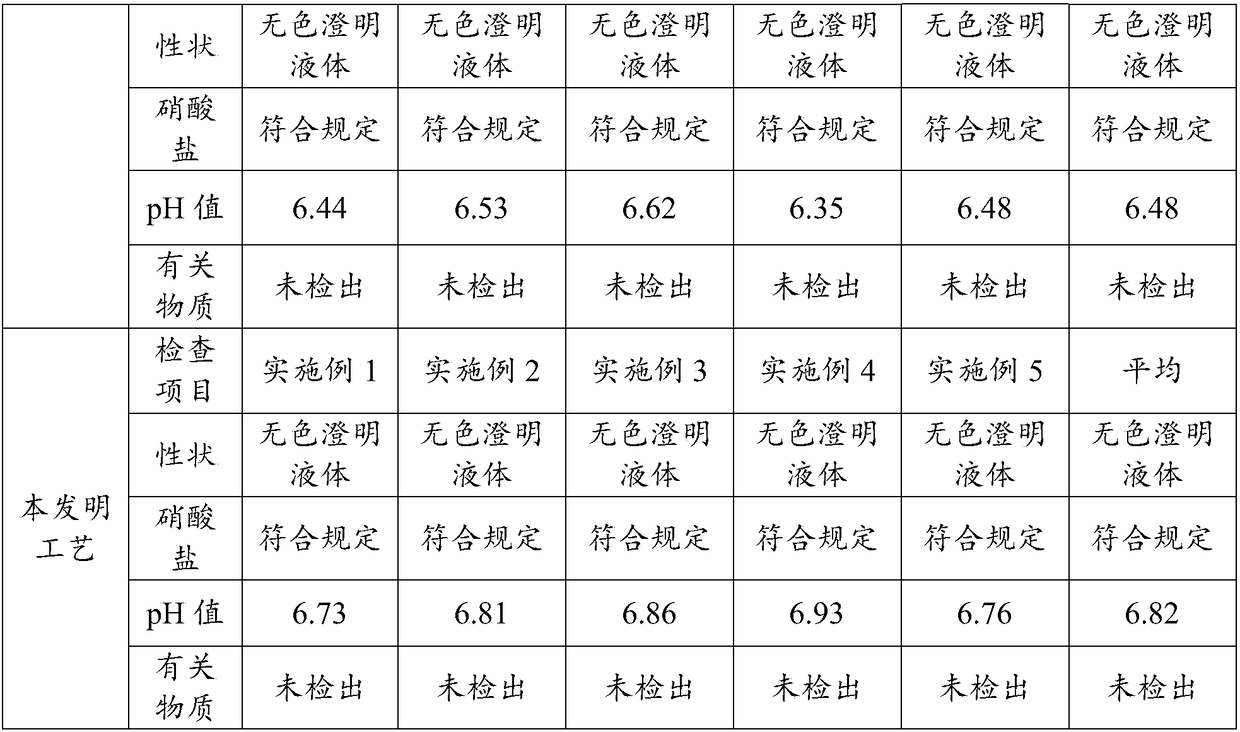

Examples

Embodiment 1

[0026] An embodiment of the method for preparing nitroglycerin of the present invention comprises the following steps: (1) Nitration reaction: Weigh 3 parts of fuming nitric acid cooled to 10°C, add it to a reaction vessel placed in an ice bath, and slowly add it while stirring Mix 6 parts of concentrated sulfuric acid cooled to 10°C evenly to obtain a mixed acid; when the mixed acid cools down to 10°C, slowly add 1 part of glycerol dropwise while stirring, and control the temperature of the reaction solution at 12°C during the dropping process; After the dropwise addition, continue to stir at 12°C for 0.8h, and after standing to separate layers, discard the acid solution in the lower layer to obtain crude nitroglycerin;

[0027] (2) Refining: A, purified water washing: transfer the nitroglycerin crude product obtained in step (1) into a separatory container with an equal volume of purified water in advance, shake and wash fully, leave to stand for stratification, discard the u...

Embodiment 2

[0029] An embodiment of the method for preparing nitroglycerin of the present invention comprises the following steps: (1) Nitration reaction: Weigh 1 part of fuming nitric acid cooled to 6° C., add it to a reaction vessel placed in an ice bath, and slowly add it while stirring. Mix 2 parts of concentrated sulfuric acid cooled to 6°C evenly to obtain a mixed acid; when the mixed acid cools down to 15°C, slowly add 0.5 parts of glycerol dropwise while stirring, and control the temperature of the reaction solution at 18°C during the dropping process; After the dropwise addition, continue to stir at 18°C for 0.5h, and after standing to separate layers, discard the acid solution in the lower layer to obtain crude nitroglycerin;

[0030] (2) Refining: A, purified water washing: transfer the nitroglycerin crude product obtained in step (1) into a separatory container with an equal volume of purified water in advance, shake and wash fully, leave to stand for stratification, discar...

Embodiment 3

[0033] An embodiment of the method for preparing nitroglycerin of the present invention comprises the following steps: (1) Nitration reaction: Weigh 3.5 parts of fuming nitric acid cooled to 9° C., add it to a reaction vessel placed in an ice bath, and slowly add it while stirring. 5.5 parts of concentrated sulfuric acid cooled to 9°C, mixed evenly to obtain a mixed acid; when the temperature of the mixed acid was lowered to 15°C, slowly add 1 part of glycerol dropwise while stirring, and the temperature of the reaction solution was controlled at 12°C during the dropping process; After the dropwise addition, continue to stir at 12°C for 0.7h, and after standing to separate layers, discard the acid solution in the lower layer to obtain crude nitroglycerin;

[0034] (2) Refining: A, purified water washing: transfer the nitroglycerin crude product obtained in step (1) into a separatory container with an equal volume of purified water in advance, shake and wash fully, leave to stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com