Method of synthesizing isooctyl nitrate

A technology of isooctyl nitrate and nitric acid, which is applied in the field of synthesis of isooctyl nitrate (2-EHN), can solve the problems of increasing operation steps and subsequent separation steps, increasing the cost of raw materials, etc., so as to simplify post-processing and facilitate recycling , high mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Use 98% sulfuric acid and 98% nitric acid to prepare a mixed acid with a molar ratio of sulfuric acid and nitric acid of 1.35:1.

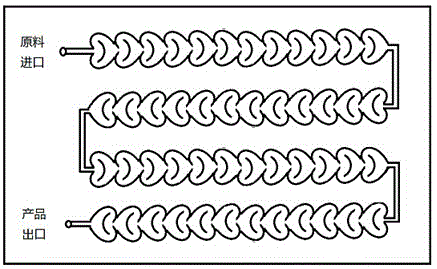

[0027] Use a heating and cooling circulator to heat and cool the reactor. Set the temperature of the reactor at 10°C. After the temperature is stable, pump the mixed acid into the reactor at a flow rate of 32mL / min; pump isooctanol into the reactor In the process, the flow rate is controlled at 40mL / min, the material reacts in the microchannel reactor, the reaction residence time is 8s, and the reaction pressure is 0.5MPa. The phase is washed with water, alkali and washed with water until neutral, and dried to remove moisture. Isooctyl nitrate is colorless and transparent, with a purity of 98.70% and a yield of 96.50%.

Embodiment 2

[0029] Use 98% sulfuric acid and 98% nitric acid to prepare a mixed acid with a molar ratio of sulfuric acid and nitric acid of 1.80:1.

[0030] Use a heating and cooling circulator to heat and cool the reactor. Set the temperature of the reactor at 10°C. After the temperature is stable, pump the mixed acid into the reactor with a flow rate of 36mL / min; pump isooctanol into the reactor In the process, the flow rate is controlled at 36mL / min, the material reacts in the microchannel reactor, the reaction residence time is 8s, and the reaction pressure is 0.5MPa. The phase is washed with water, alkali and washed with water until neutral, and dried to remove moisture. Isooctyl nitrate is colorless and transparent, with a purity of 99.92% and a yield of 98.54%.

Embodiment 3

[0032] Use 98% sulfuric acid and 98% nitric acid to prepare a mixed acid with a molar ratio of sulfuric acid and nitric acid of 1.80:1.

[0033] Heating and refrigeration circulators are used to heat and cool the reactor. Set the temperature of the reactor to 20°C. After the temperature is stable, pump the mixed acid into the reactor with a flow rate of 36mL / min; pump isooctanol into the reactor In the process, the flow rate is controlled at 36mL / min, the material reacts in the microchannel reactor, the reaction residence time is 8s, and the reaction pressure is 0.5MPa. The phase is washed with water, alkali and washed with water until neutral, and dried to remove moisture. Isooctyl nitrate is colorless and transparent, with a purity of 98.51% and a yield of 96.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com