Continuous synthesis method for 2-ethylhexyl nitrate

A technology of isooctyl nitrate and a synthesis method, applied in the field of continuous synthesis of isooctyl nitrate, can solve the problems of weakened adsorption and dehydration ability, easy agglomeration of anhydrous sodium sulfate, high investment and operating costs, and achieves elimination of flying temperature explosion. Dangerous, improved process safety, fast mass and heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

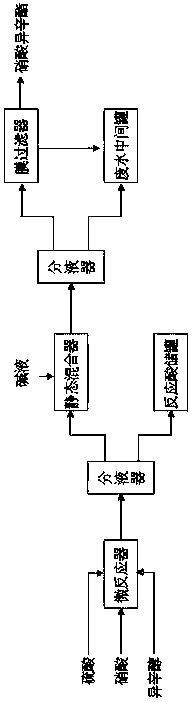

[0029] See attached figure 1 , the reactor is heated and refrigerated by a heating and cooling circulator, and the reaction temperature is controlled at 4°C. At a certain temperature, concentrated nitric acid, concentrated sulfuric acid and isooctyl alcohol are pumped into the microchannel reactor, and the flow rate of the pump is controlled to maintain The molar ratio of sulfuric acid and nitric acid is 3.0, and the molar ratio of isooctyl alcohol to nitric acid is 1.08; The solution time is 5 minutes, and the crude product of the upper layer of acidic isooctyl nitrate enters the crude product storage tank of acidic isooctyl nitrate; the reaction acid of the lower layer goes to the reaction acid storage tank.

[0030] Put the crude isooctyl nitrate into the static mixer at 200ml / min and liquid caustic soda at 8ml / min, mix in the static mixer and then enter the oil-water liquid device, stay for 5 minutes, let it stand for stratification and then flow out continuously, the uppe...

Embodiment 2

[0032] Process is with embodiment 1, and sulfuric acid and nitric acid mol ratio are changed into 2.5.

[0033] Isooctyl nitrate is light yellow and transparent, with a purity of 99.23%, a yield of 99.14%, and a water content of 40ppm.

Embodiment 3

[0035] Process is with embodiment 1, and sulfuric acid and nitric acid mol ratio are changed into 3.5.

[0036] Isooctyl nitrate is colorless and transparent, with a purity of 99.65% and a yield of 99.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com