Continuous production process of isooctyl nitrate

A technology of isooctyl nitrate and a production process, applied in the petrochemical field, can solve the problems of large heat generation, high temperature explosion, low production efficiency, etc., and achieves the effects of less investment, easy industrialization, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

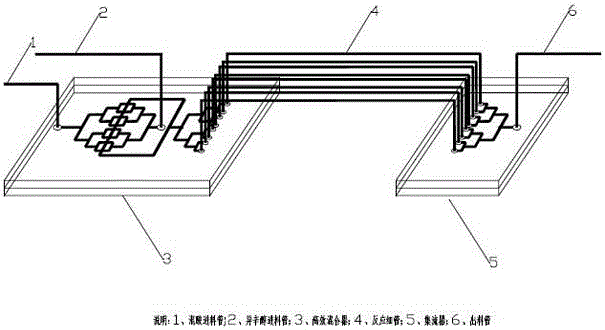

Image

Examples

Embodiment 1

[0018] A continuous production process for isooctyl nitrate, comprising the following steps:

[0019] The first step: measure concentrated sulfuric acid and concentrated nitric acid through a metering tank, and put them into a stirring tank at a volume ratio of 0.8 to stir and mix evenly;

[0020] Step 2: inject the mixed acid and isooctyl alcohol into two coolers through the metering pump according to the volume flow ratio of 1 for cooling. After the temperature is 15°C, inject them into the reactor assembly for mixed reaction. Mix first in the high-efficiency mixer, and the mixing time is 10ms;

[0021] Step 3: The uniformly mixed material enters the narrow reaction tube through the distribution tank for reaction. Cooling water is passed around the narrow tube. The reaction time is 23s, the temperature of the cooling water is 10°C, and the flow rate is 3.0m / s;

[0022] Step 4: The reaction product is collected by the current collector and then enters the centrifuge for este...

Embodiment 2

[0027] A continuous production process for isooctyl nitrate, comprising the following steps:

[0028] The first step: measure concentrated sulfuric acid and concentrated nitric acid through a metering tank, and put them into a stirring tank at a volume ratio of 0.7 to stir and mix evenly;

[0029] Step 2: inject the mixed acid and iso-octanol into two coolers through the metering pump according to the volume flow ratio of 0.91 for cooling. After the temperature is 13°C, inject them into the reactor assembly for mixed reaction. Mix first in the high-efficiency mixer, and the mixing time is 15ms;

[0030] Step 3: The uniformly mixed material enters the narrow reaction tube through the distribution tank for reaction. Cooling water is passed around the narrow tube. The reaction time is 15s, the temperature of the cooling water is 12°C, and the flow rate is 2.5m / s;

[0031] Step 4: The reaction product is collected by the current collector and then enters the centrifuge for ester ...

Embodiment 3

[0036] A continuous production process for isooctyl nitrate, comprising the following steps:

[0037] The first step: measure concentrated sulfuric acid and concentrated nitric acid through a metering tank, and put them into a stirring tank at a volume ratio of 0.4 to stir and mix evenly;

[0038] Step 2: Inject the mixed acid and isooctyl alcohol into two coolers with a volume flow ratio of 0.6 through the metering pump for cooling. After the temperature is 10°C, inject them into the reactor assembly for mixed reaction. Mix first in the high-efficiency mixer, and the mixing time is 5ms;

[0039] Step 3: The uniformly mixed material enters the narrow reaction tube through the distribution tank for reaction. Cooling water is passed around the narrow tube. The reaction time is 5s, the temperature of the cooling water is 15°C, and the flow rate is 1.5m / s;

[0040] Step 4: The reaction product is collected by the current collector and then enters the centrifuge for ester acid sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com