Production method of isooctyl nitrate

A technology of isooctyl nitrate and production method, applied in the directions of nitrate preparation, chemical instruments and methods, mixers, etc., can solve the problems of low space-time efficiency, uneven material distribution, low reaction space velocity conditions and the like, and achieve product high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

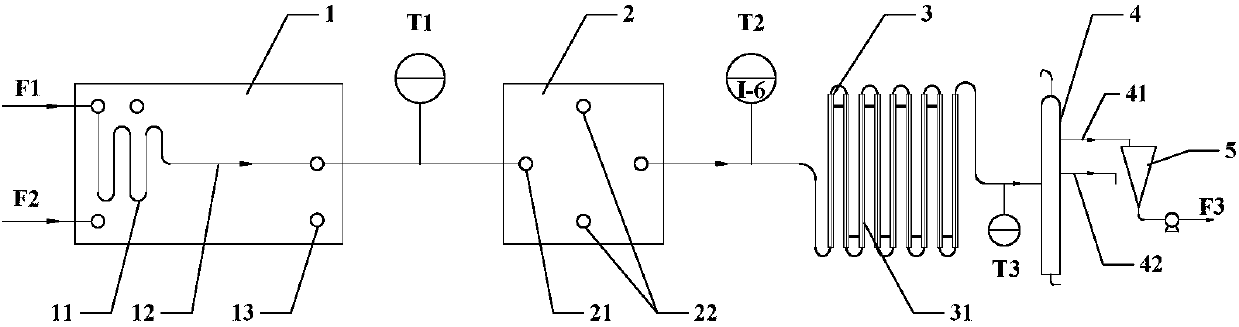

[0021] Nitrification process equipment: The micromixer is made of two Inconel 600 plates after chemically etched into the microchannels and manufactured by vacuum diffusion welding. According to the requirements of the present invention, the length, width, and depth of the inlet channel of the micromixer are respectively designed and processed to 150mm, 3mm, 0.75mm, 16 mixing channels, 100mm, 1mm and 0.75mm in length, width and depth respectively. There are 32 side channels of the reaction material in the micro heat exchanger, and the length, width and depth are the same as the mixing channel of the micro mixer. After the micro heat exchanger is connected to a Ф20×2.5×3000mm single-tube reactor with a sleeve heat exchange, the outlet of the single-tube reactor is connected with a glass automatic separator to separate the ester mixture. The single tube reactor casing and the heat transfer channels of the micro heat exchanger and the micro mixer are connected in series, and the h...

Embodiment 2

[0028] Nitrification process equipment: The micromixer is made of 1 Inconel 600 plate after chemically etched out of the microchannels and manufactured by vacuum diffusion welding. The length, width, and depth of the inlet channel of the micromixer are 150mm, 3mm, and 0.5mm respectively, and the mixing channel is 8 The length, width and depth are 100mm, 1mm and 0.5mm respectively. There are 32 side channels of the reaction material in the micro heat exchanger, and the length, width and depth are the same as the mixing channel of the micro mixer. After the micro heat exchanger is connected to a Ф6×1×6000mm single-tube reactor, the outlet of the single-tube reactor is connected with a glass automatic separator to separate the ester mixture. The heat exchange channels of the micro heat exchanger and the micro mixer are connected in series, and a constant flow pump with a maximum flow of 60L / h is used to transfer the heat of 20℃ tap water.

[0029] The raw material preparation and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com