System and process for dehydrating and drying isooctyl nitrate crude product

A technology of isooctyl nitrate and drying system is applied in the production field of petrochemical product nitrate, can solve problems such as low production efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

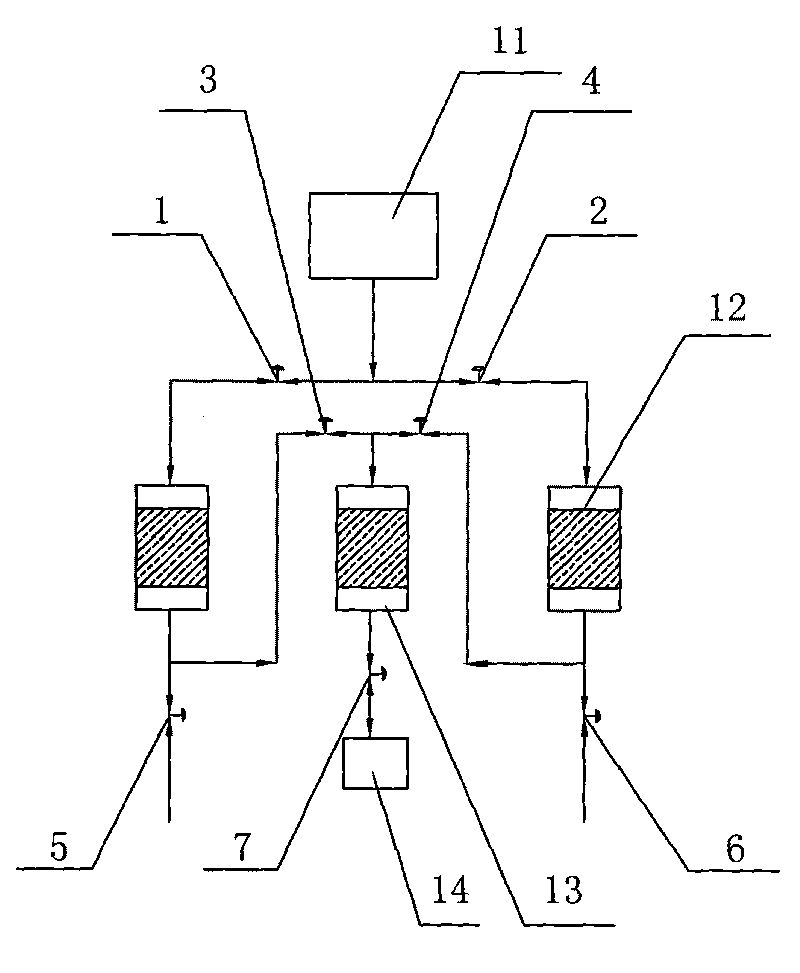

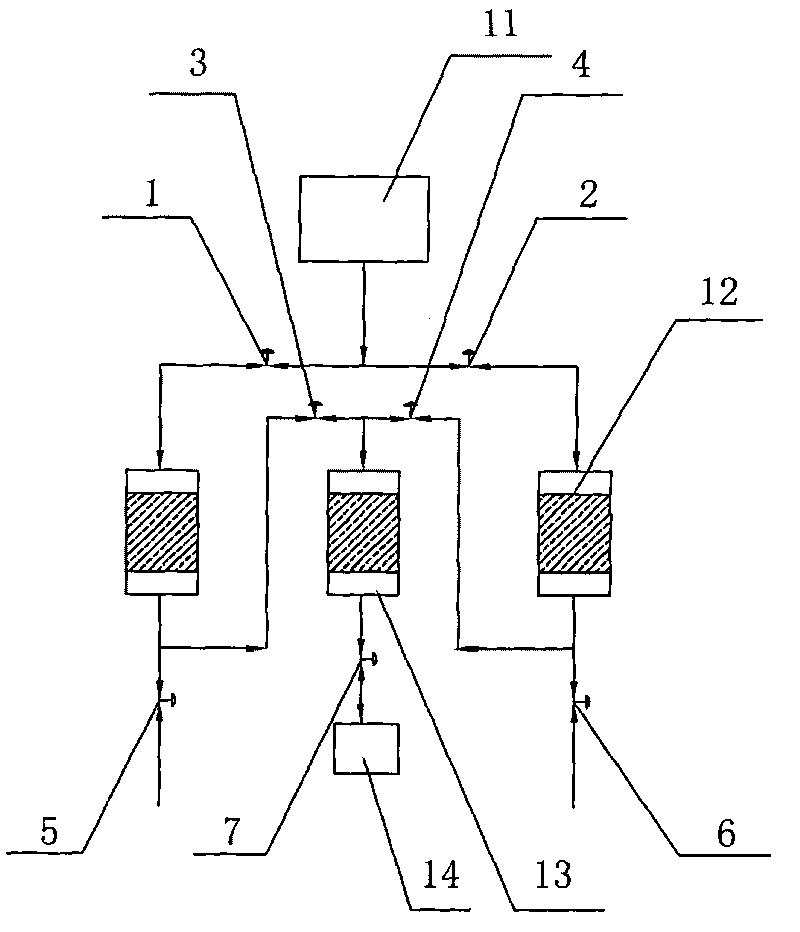

[0022] The present invention will be described in detail below with reference to the accompanying drawings.

[0023] A kind of drying system of isooctyl nitrate crude product, comprise the crude product tank 1 that pump is connected successively, rough take off component, fine take off component and product tank 4, described rough take off component and comprise two silica gel rough off devices 2 that are connected in parallel, The fine eliminator assembly includes a molecular sieve fine eliminator 3 . Said silica gel coarse stripper 2 and molecular sieve fine stripper 3 are all made of a cylindrical shell, a distributor arranged in the upper part of the shell, a built-in support structure in the bottom of the shell, and a wire mesh set in the upper part of the support structure. Granular color-changing silica gel is placed on the screen of device 2 as a dehydrating agent; 5A molecular sieve particles are placed on the screen of molecular sieve fine eliminator 3 as a dehydrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com