Prospective intelligent control method and device for fluid printing color film

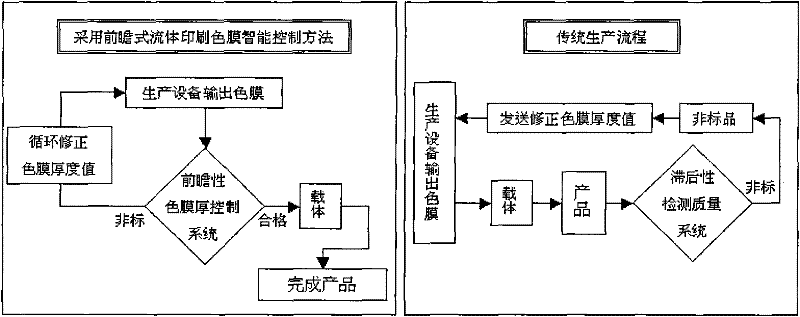

A technology of intelligent control and printing color, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of correcting completion time errors, increasing the number of defective products, delaying adjustment time, etc., to reduce loss and limitless The effect of reproducible production and rapid adjustment of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

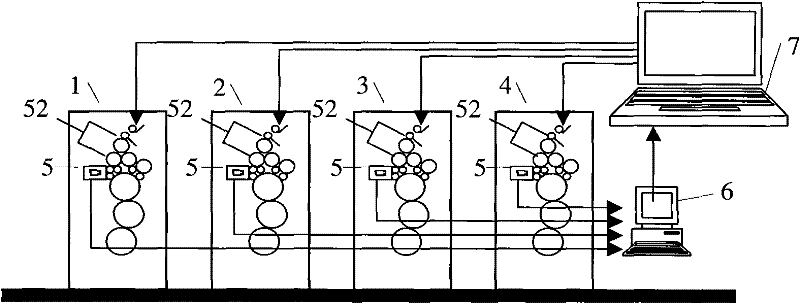

[0089] Embodiment 1: A forward-looking fluid printing color film intelligent control method and device

[0090] see figure 2 , including: production equipment console (7), production units 1, 2, 3 and 4, grinding system (52), scanner (5) and neutral gray balance analyzer (6). Its production color group units 1, 2, 3 and 4 are freely arranged according to requirements and placed black, cyan, magenta and yellow pigments on the storage tank. Input the preset black color value to the neutral gray balance analyzer (6) as a reference for neutral gray balance production. The analyzer prepares the correspondence table between the thickness of the printed color film and the amount of the monitored material in advance ( Figure 20 ) to determine the thickness of the grinding printing color film. Black, cyan, magenta, and yellow color zone scanners (5) measure the printing color film sampling thickness (9), and actively provide a neutral gray balance analyzer (6) and preset black colo...

Embodiment 2

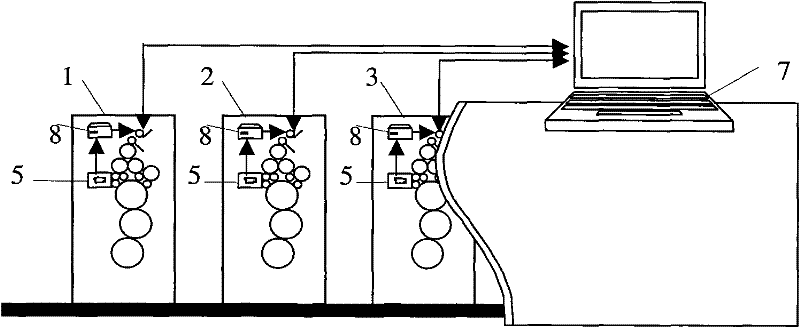

[0091] Example 2: An independent regional production unit forward-looking fluid printing color film intelligent control device

[0092] see image 3 , Each production color group such as: Unit 1 can choose a special color for production. The scanner (5) extracts the color value data of its color group unit in a regional active look-ahead manner. Uneven color zone results will be directly sent to the color zone controller (8) of the color group for real-time cyclic correction without correction through the console (7). The operator can also use the device console (7) to select the color zone value. Other similarities with the above embodiments will not be repeated.

Embodiment 3

[0093] Embodiment 3: A forward-looking fluid printing color film intelligent control device with a built-in monitor

[0094] see Figure 4 , production equipment machine structure (13). The single monitoring instrument fixes the rotating shaft (10), and the measuring probe (5) operates back and forth in the direction of the arrow. Along the motorized rotating shaft (10), the probe is driven back and forth to scan the surface of the color film thickness sampling rotating shaft (9) accurately. The reading value of the film thickness is connected by optical, electrical and digital transmission (11), and the data is transmitted to the operation system of the PLC program control cabinet (12), and the conversion result becomes digital, which is used as an active and forward-looking production system for continuous monitoring and correction. use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com