Method for continuously synthesizing 2-ethylhexyl nitrate in micro-reactors and extracting residual acid in 2-ethylhexyl nitrate

A technology of isooctyl nitrate and micro-reactor, which is applied in the field of synthesis and refining of isooctyl nitrate, can solve the problems of long time consumption, high energy consumption, high production cost, etc., and achieve the effect of avoiding difficult deacidification and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

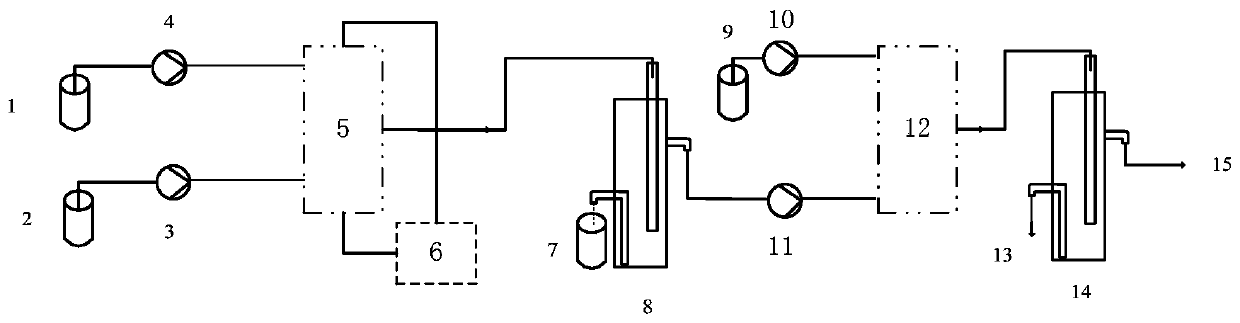

Method used

Image

Examples

Embodiment 1

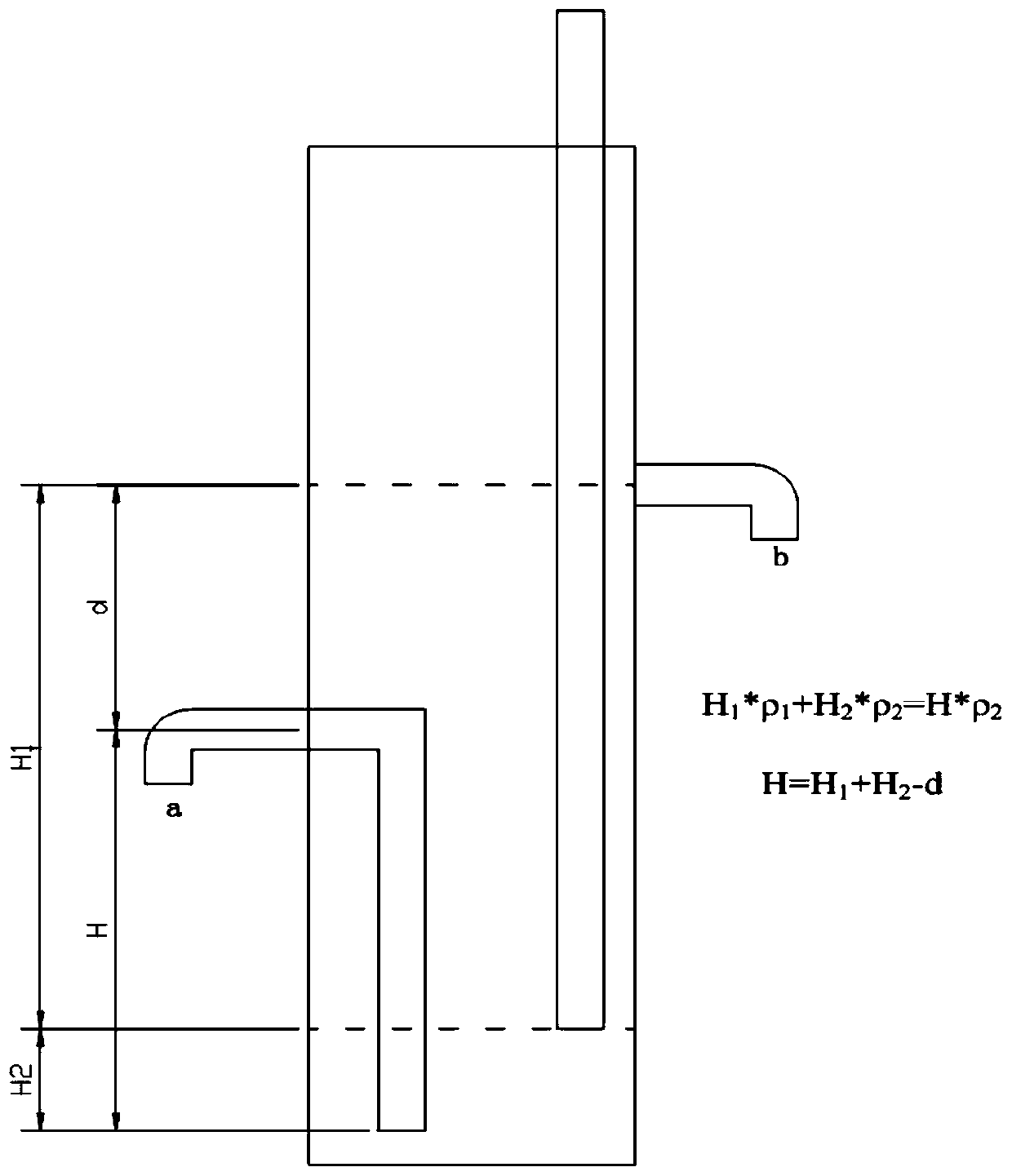

[0029] Isooctyl alcohol and sulfur / nitrate mixed acid are squeezed into the first microreactor by two metering pumps to react respectively, the mol ratio of described sulfur / nitrate mixed acid is 2, and the mol ratio of nitric acid and isooctyl alcohol is 1.1:1, reaction The temperature is a constant temperature of 55°C, and the residence time of the nitrification reaction is about 30s. Wait for about 25 minutes, after the liquid two-phase interface in the separator reaches a stable state, the EHN crude product separated from the b port of the separator and the 0.5mol / L NaOH aqueous solution are pumped into the second microreactor by two metering pumps respectively, The extraction flow rate of the EHN crude product and the flow rate of isooctyl alcohol are both 1ml / min, the flow rate of the NaOH aqueous solution is 2.5ml / min, the extraction residence time of the acid-base reaction in the second microreactor is 9s, and the sample is collected at the end of the reaction Carry ou...

Embodiment 2

[0031] The process is the same as in Example 1, except that the reaction temperature in the synthesis stage of isooctyl nitrate is changed to 45° C., and the yield of isooctyl nitrate is 92.7%.

Embodiment 3

[0033] The process is the same as in Example 1, except that the concentration of the NaOH aqueous solution in the extraction stage is changed to 1.0 mol / L, and the extraction rate of residual acid in EHN is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com