Method for preparing high-specific-surface-area macroporous-mesoporous carbon by using salt template, and applications of high-specific-surface-area macroporous-mesoporous carbon

A high specific surface area, mesoporous carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of easy residue, increased operation difficulty, raw material cost, cumbersome template processing process, etc., and achieves low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take 1 g of gelatin in 20 mL of deionized water, heat up to 80 °C, wait until the gelatin is completely dissolved, stir to make it evenly dispersed, then add 0.25 g of sodium nitrate, stir to dissolve to form a homogeneous sol, and cool to room temperature.

[0042] The above sol was placed in a constant temperature box at 4 °C for 12 h to form a hydrogel, and then placed at -20 °C for 12 h, and then immersed in liquid nitrogen for 1-5 min to obtain a jelly.

[0043] The jelly was placed in a freeze dryer and vacuum freeze-dried for 36 h to obtain an aerogel.

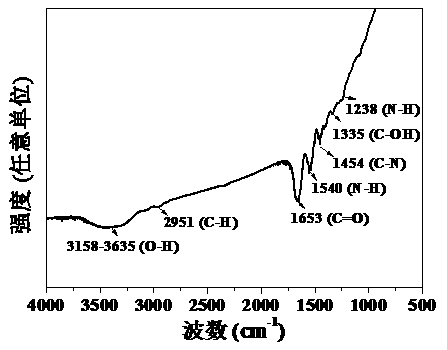

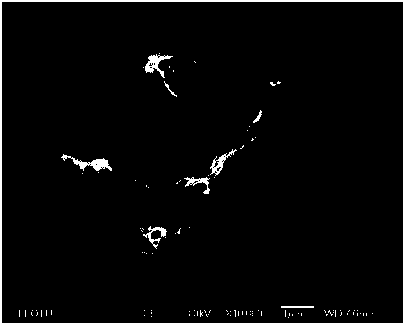

[0044] The airgel was placed in a tube furnace, fed with argon, raised to 800 °C at a rate of 5 °C / min, and kept at 800 °C for 1 h, and cooled to room temperature naturally to obtain a black carbonized product.

[0045] Collect the black carbonized product, put it in a beaker, add deionized water, stir and wash for 2 h, filter with suction, wash, and dry to obtain the final product, which is marked as C-0.25-800....

Embodiment 2

[0048] Take 1 g of gelatin in 20 mL of deionized water, heat up to 80 °C, until the gelatin is completely dissolved, stir to disperse evenly, then add 0.5 g of sodium nitrate, stir to dissolve to form a homogeneous sol, and cool to room temperature.

[0049] The above sol was placed in a constant temperature box at 4 °C for 12 h to form a hydrogel, and then placed at -20 °C for 12 h, and then immersed in liquid nitrogen for 1-5 min to obtain a jelly.

[0050] The jelly was placed in a freeze dryer and vacuum freeze-dried for 36 h to obtain an aerogel.

[0051] The airgel was placed in a tube furnace, fed with argon, raised to 800 °C at a rate of 5 °C / min, and kept at 800 °C for 1 h, and cooled to room temperature naturally to obtain a black carbonized product.

[0052] Collect the black carbonized product, put it in a beaker, add deionized water, stir and wash for 2 h, filter with suction, wash, and dry to obtain the final product, which is marked as C-0.5-800.

[0053] The m...

Embodiment 3

[0055] Take 1 g of gelatin in 20 mL of deionized water, heat up to 80 °C, wait until the gelatin is completely dissolved, stir to disperse evenly, then add 0.75 g of sodium nitrate, stir to dissolve to form a homogeneous sol, and cool to room temperature.

[0056] The above sol was placed in a constant temperature box at 4 °C for 12 h to form a hydrogel, and then placed at -20 °C for 12 h, and then immersed in liquid nitrogen for 1-5 min to obtain a jelly.

[0057] The jelly was placed in a freeze dryer and vacuum freeze-dried for 36 h to obtain an aerogel.

[0058] The airgel was placed in a tube furnace, fed with argon, raised to 800 °C at a rate of 5 °C / min, and kept at 800 °C for 1 h, and cooled to room temperature naturally to obtain a black carbonized product.

[0059] Collect the black carbonized product, put it in a beaker, add deionized water, stir and wash for 2 h, filter with suction, wash, and dry to obtain the final product, which is marked as C-0.75-800.

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Large hole size | aaaaa | aaaaa |

| Mesopore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com