Floatation device

A flotation device and flotation column technology, which is applied in flotation, solid separation, etc., can solve the problems of less chance of mineralized foam floating up, increased processing difficulty, and inability to uniformly fill the bubbles, so as to improve mineral mineralization chance, reduce the difficulty of maintenance, and evenly distribute the foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

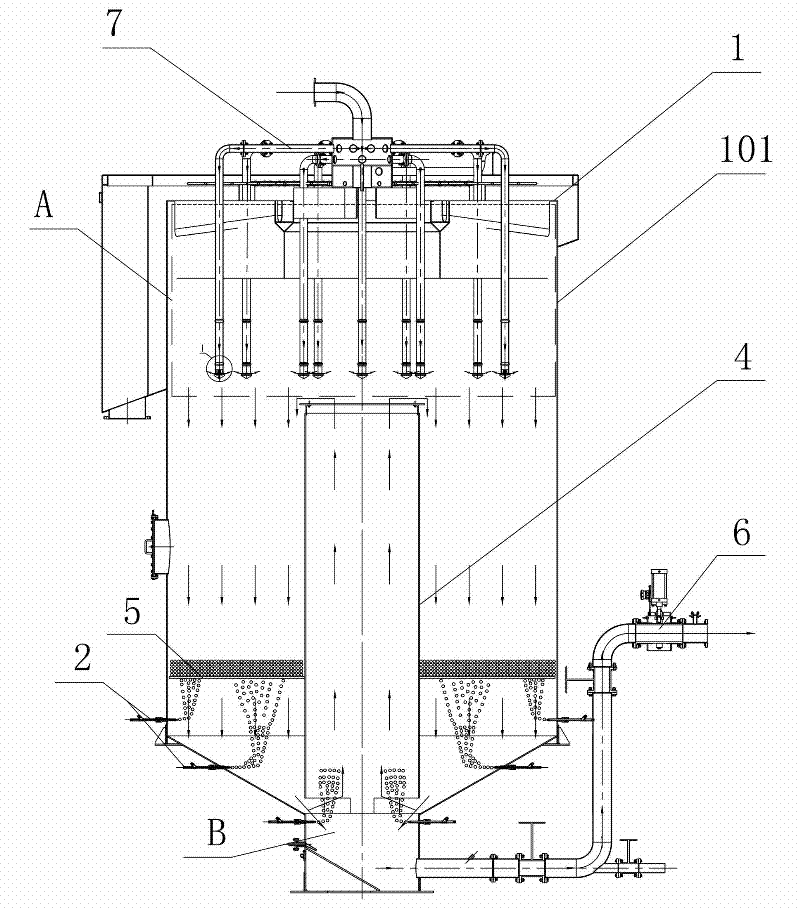

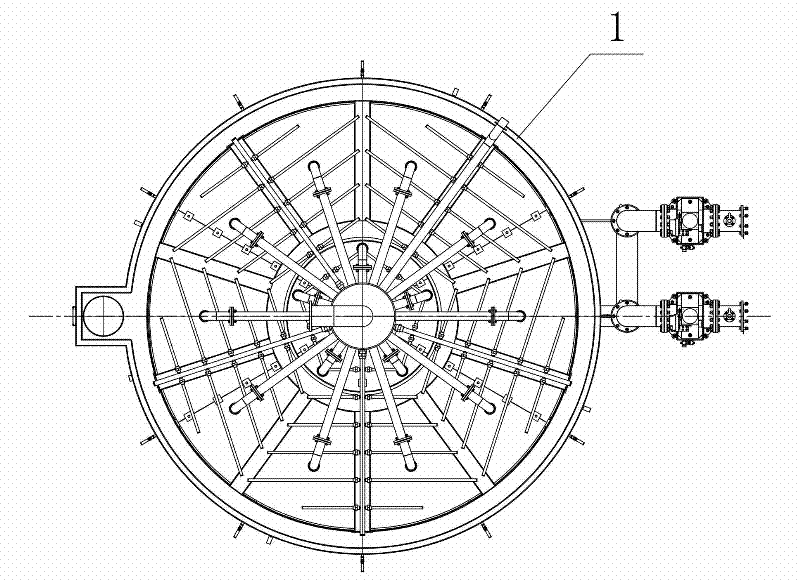

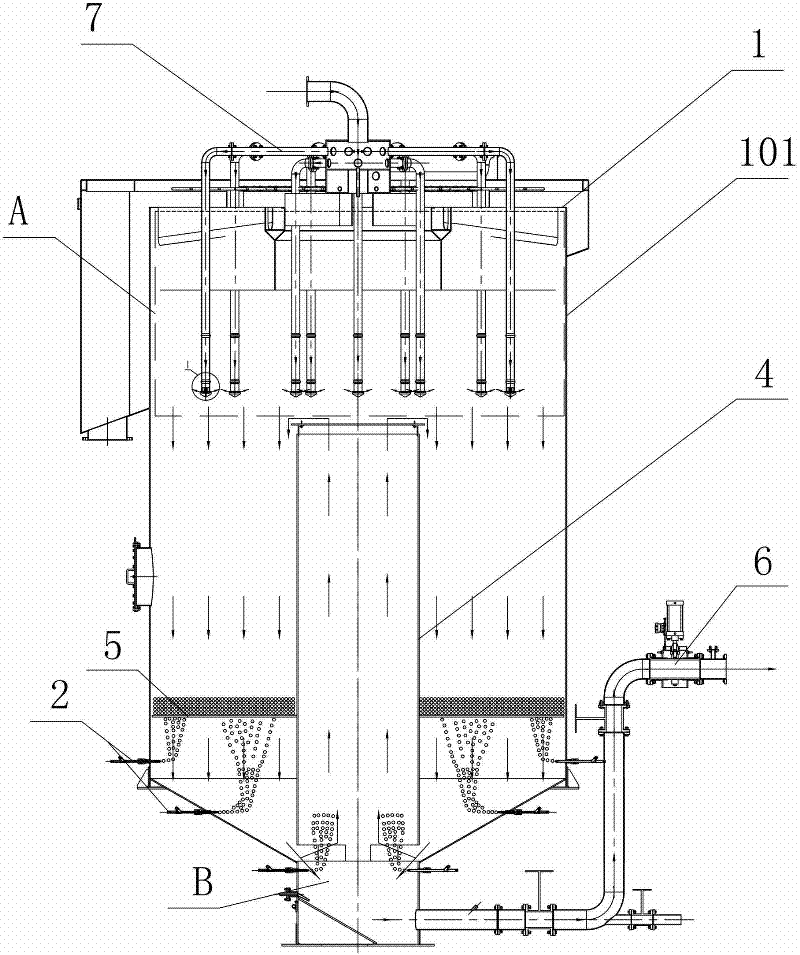

[0024] Such as figure 1 and figure 2 As shown, the flotation device of the present invention comprises a flotation column 1, a feed assembly 7 and a tailings discharge assembly 6 connected to the bottom of the flotation column 1, and the feed assembly 7 is positioned at the top of the flotation column 1, vertically Bottom layout, the slurry is fed from top to bottom; area A in the figure is the concentrate area, and area B in the figure is the tailings area. In the present invention, a scavenging channel 4 is provided in the column body 101 of the flotation column 1 . The sweeping channel 4 is tubular and located in the middle of the cylinder 101 , arranged along the vertical direction, with the lower end being the inlet end and the upper end being the outlet end. The inlet end is slightly higher than a part of the air-filled spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com