Building cement stirring mixing system and method

A technology for stirring and mixing, construction cement, applied in the field of mixing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

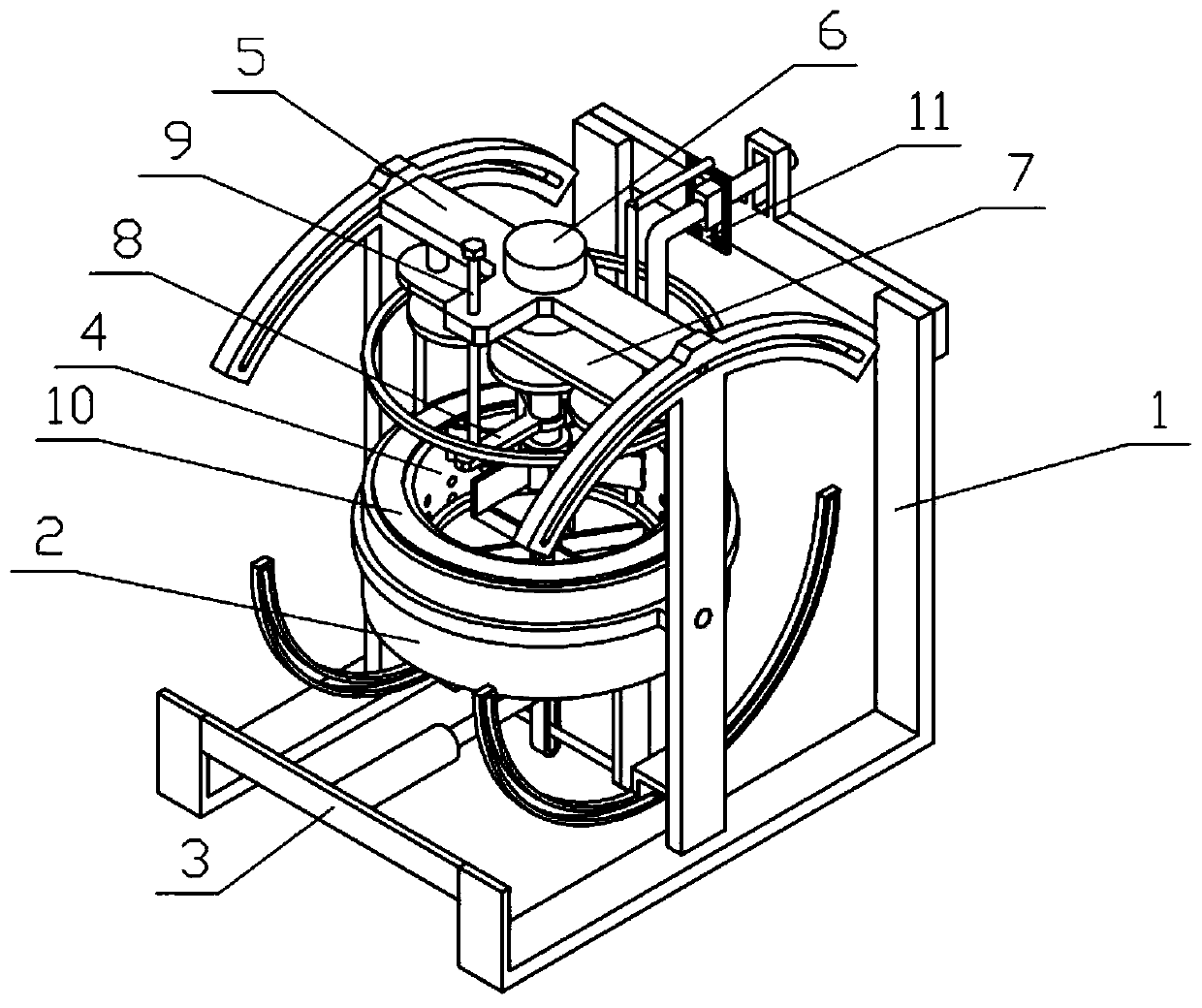

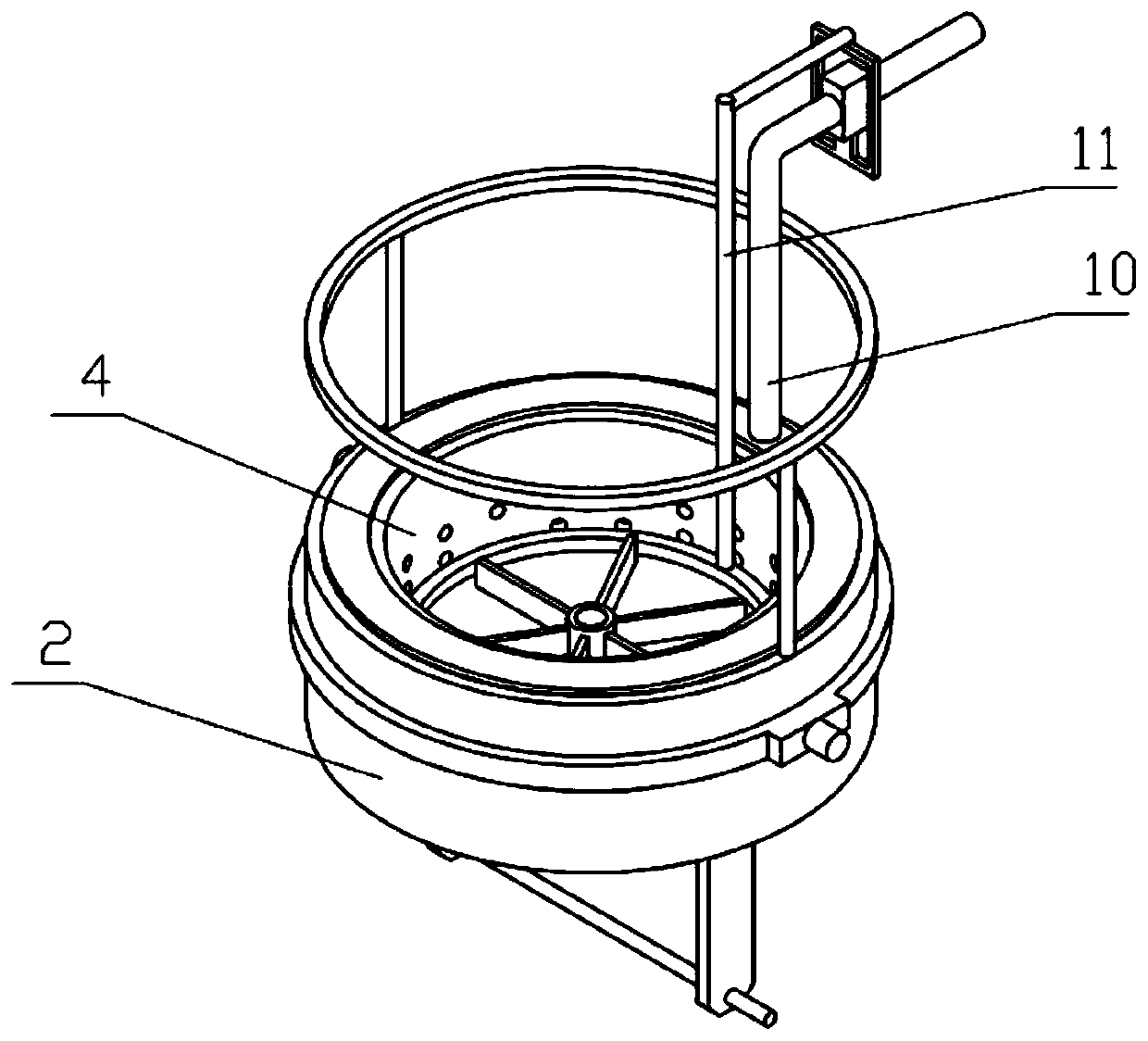

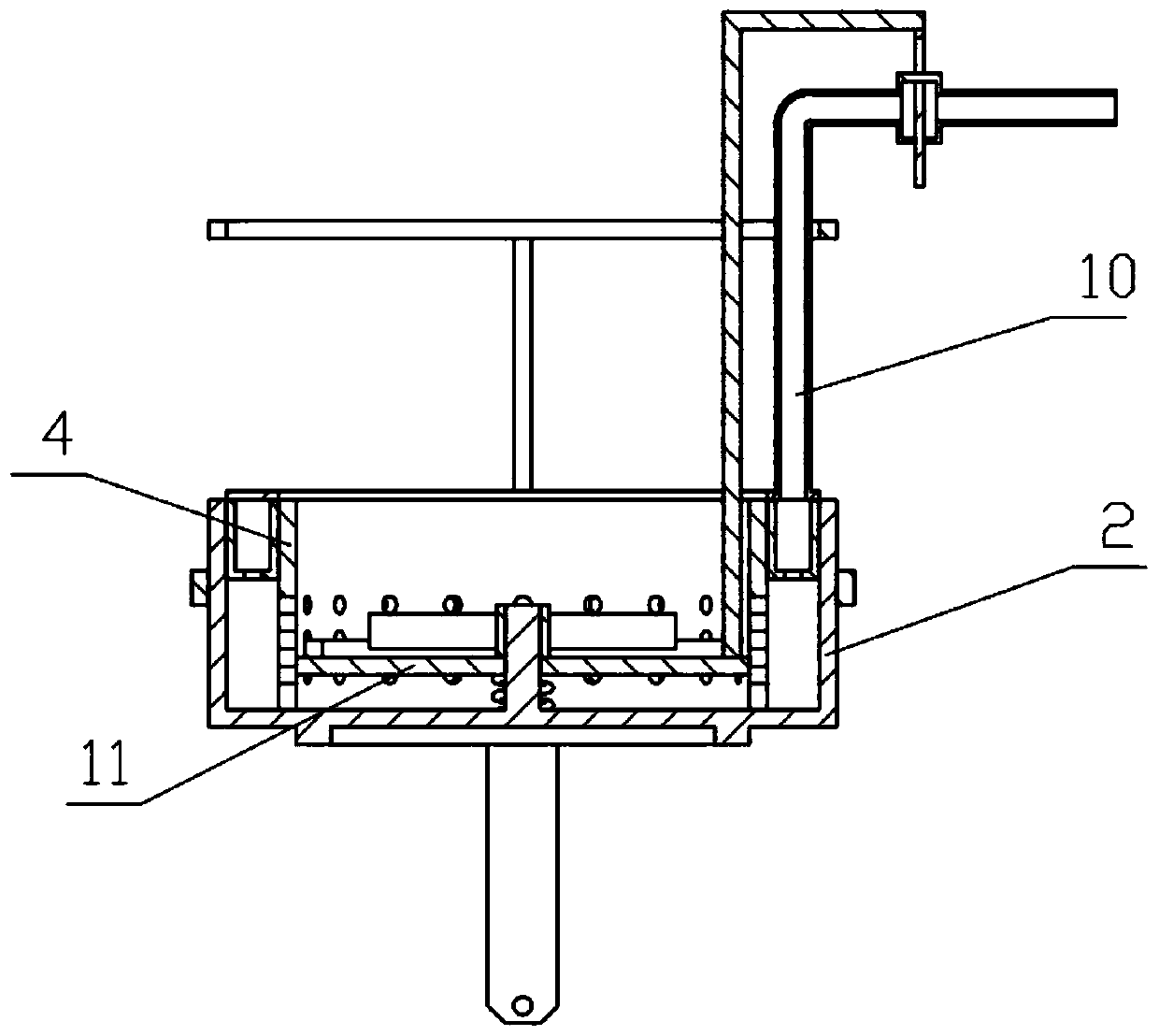

[0048] Combine below Figure 1-17 Describe this embodiment, a construction cement mixing and mixing system, including an integral support 1, a mixing support 2, a pushing mechanism 3, a mixing cylinder 4, a swinging support 5, a power mechanism 6, a planetary mechanism 7, a stirring mechanism 8, and a lifting screw 9 , the water inlet mechanism 10 and the sliding bracket 11, the middle part of the mixing bracket 2 is rotatably connected to the overall bracket 1, the lower end of the mixing bracket 2 is slidingly connected to the overall bracket 1, the pushing mechanism 3 is fixedly connected to the overall bracket 1, and the mixing bracket The lower end of 2 is slidably connected to the pushing mechanism 3, the mixing cylinder 4 is fixedly connected to the inner side of the mixing support 2, the swing support 5 is slidably connected to the overall support 1, the power mechanism 6 is fixedly connected to the swing support 5, and the planetary mechanism 7 is fixedly connected On...

specific Embodiment approach 2

[0050] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the overall bracket 1 includes a bottom plate 1-1, a support plate I1-2, a connecting plate 1-3, a support plate II1-4, and an arc plate I1-5 , arc groove I1-6, arc plate II1-7 and arc groove II1-8, two base plates 1-1 are provided, and the rear ends of the two base plates 1-1 are fixedly connected with support plate I1-2, A connection plate 1-3 is fixedly connected between the upper ends of the two support plates I1-2, a support plate II1-4 is fixedly connected to the middle parts of the two bottom plates 1-1, and the lower ends of the two support plates II1-4 are fixedly connected There are arc plates Ⅰ1-5, and arc grooves Ⅰ1-6 are arranged on the two arc plates Ⅰ1-5, and the upper ends of the two support plates Ⅱ1-4 are fixedly connected with arc plates Ⅱ1-7, and the two circles Arc grooves II1-8 are arranged on arc plates II1-7; the centers of arc plates ...

specific Embodiment approach 3

[0052] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain Embodiment 2, the mixing bracket 2 includes a mixing outer cylinder 2-1, a rotating ring 2-2, a swing plate 2-3, a swing rod 2-4, and a swing support ring 2-5, mixing shaft 2-6, mixing impeller 2-7, connecting rod 2-8 and ring gear 2-9, the lower end of mixing outer cylinder 2-1 is connected with rotating ring 2-2, rotating ring 2-2 The lower end of the swing plate 2-3 is fixedly connected with a swing plate 2-3, and the lower end of the swing plate 2-3 is fixedly connected with a swing rod 2-4, and the two ends of the swing rod 2-4 are respectively slidably connected in two arc grooves I1-6, mixing The outer cylinder 2-1 is rotatably connected with a swing support ring 2-5, and the two ends of the swing support ring 2-5 are respectively rotatably connected with two support plates II 1-4, and the inside of the mixing outer cylinder 2-1 is fixedly connected with a mixing Shaft 2-6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com