Lithium nickel cobalt manganese aluminate positive electrode material with shell-core-shell structure and preparation method of lithium nickel cobalt manganese aluminate positive electrode material

A technology of nickel-cobalt-manganese-aluminate lithium and core-shell structure, which is applied in the field of nickel-cobalt manganese-aluminate lithium anode material and its preparation, can solve the problem of no improvement in the thermal stability and safety performance of high-nickel ternary secondary particle anode materials , The internal layer structure deteriorates preferentially, and it is difficult to enter the secondary particles, etc., to achieve the effect of improving cycle stability, improving cycle performance, and improving particle crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. The lithium-cobalt-manganese-aluminate positive electrode material of a core-shell structure 1.01 CoO 2 @Li 1.02 Ni 0.828 co 0.08 mn 0.0 7 al 0.02 Zr 0.002 o 2 @LiBO 2 The preparation method comprises the following steps:

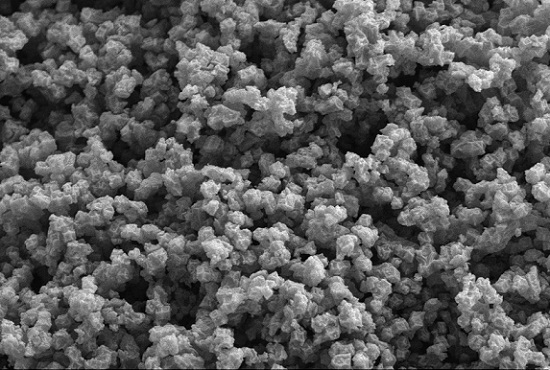

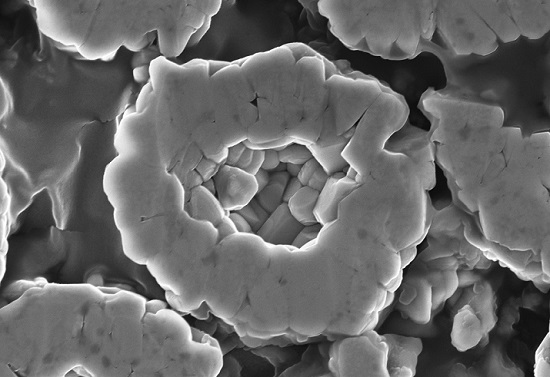

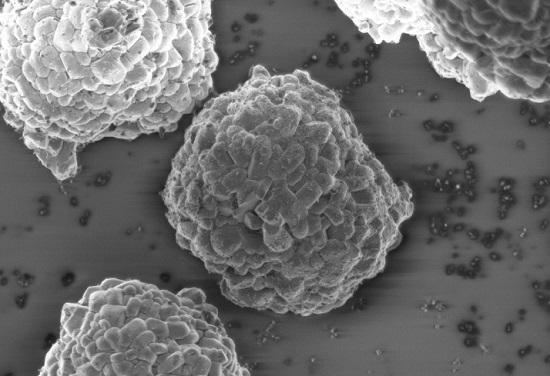

[0032] Step 1, configure 0.05mol / L Co(NO 3 ) 2 ·6H 2 O alcohol solution, then quickly add 0.40mol / L 2-methylimidazolium alcohol solution to the above solution, and stir for 30 minutes. After standing and aging at room temperature for 24 hours, the obtained purple product was precipitated and centrifuged, washed with anhydrous methanol for several times, and dried in an oven at 60° C. to obtain the zif-67 polyhedral material. The morphology of zif-67 was tested with a field emission scanning electron microscope, and the test results are shown in figure 1 .

[0033] Step 2, the molar ratio of nickel, cobalt, manganese, and aluminum is 83:8:7:2, and the concentration is 2.0mol / L mixed salt solution, 8mol / L sodium hydroxide solution, an...

Embodiment 2

[0052]1. A lithium-cobalt-manganese-aluminate positive electrode material with a shell-core-shell sandwich hollow structure 1.01 CoO 2 @Li 1.02 Ni 0.86 8 co 0.08 mn 0.03 Al 0.02 Zr 0.002 o 2 @LiAlO 2 The preparation method comprises the following steps:

[0053] Step 1, configure 0.05mol / L Co(NO 3 ) 2 ·6H 2 O alcohol solution, then quickly add 0.25mol / L 2-methylimidazolium alcohol solution to the above solution, and stir for 30 minutes. After standing and aging at room temperature for 24 hours, the obtained purple product was precipitated and centrifuged, washed with anhydrous methanol for several times, and dried in an oven at 60° C. to obtain the zif-67 polyhedral material.

[0054] Step 2, the molar ratio of nickel, cobalt, manganese, and aluminum is 87:8:3:2, and the concentration is 2.0mol / L mixed salt solution, 8mol / L sodium hydroxide solution, and 10mol / L ammonia solution.

[0055] Step 3: Turn on the stirring device of the reactor, and pump the sodium hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com