Device and method for preparing carbon nanotube

A carbon nanotube and preparation device technology, applied in the directions of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problem of uneven growth of multi-piece carbon nanotube arrays, achieve the promotion of batch preparation, and improve the uniformity of spatial distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0029] The technical solution of the invention is: a carbon nanotube preparation device.

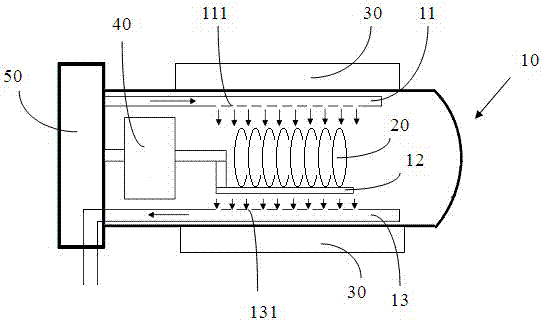

[0030] ginseng figure 1 A specific embodiment of the present invention shown is a carbon nanotube preparation device, which utilizes chemical vapor deposition to prepare multiple carbon nanotube arrays in batches, which includes a reaction chamber 10, and the reaction chamber 10 is a quartz tube with an outer diameter of 7 inches. The length of its internal constant temperature zone is 25cm.

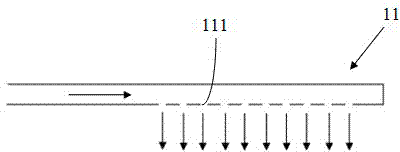

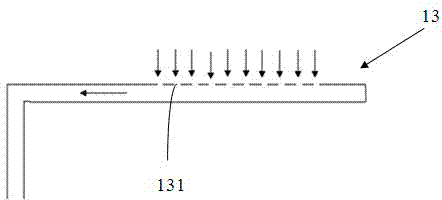

[0031] In the reaction chamber 10, at least one air inlet pipe 11, a substrate carrier plate 12 and at least one air outlet pipe 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com