Heavy hydrocarbon hydroprocessing method

A technology for hydrotreating and heavy hydrocarbons, applied in refining to remove heteroatoms, etc., can solve problems such as catalyst activity waste, catalyst imbalance, and reduced refinery profits, and achieve the goals of reducing remanufacturing, reducing operating costs, and saving infrastructure costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

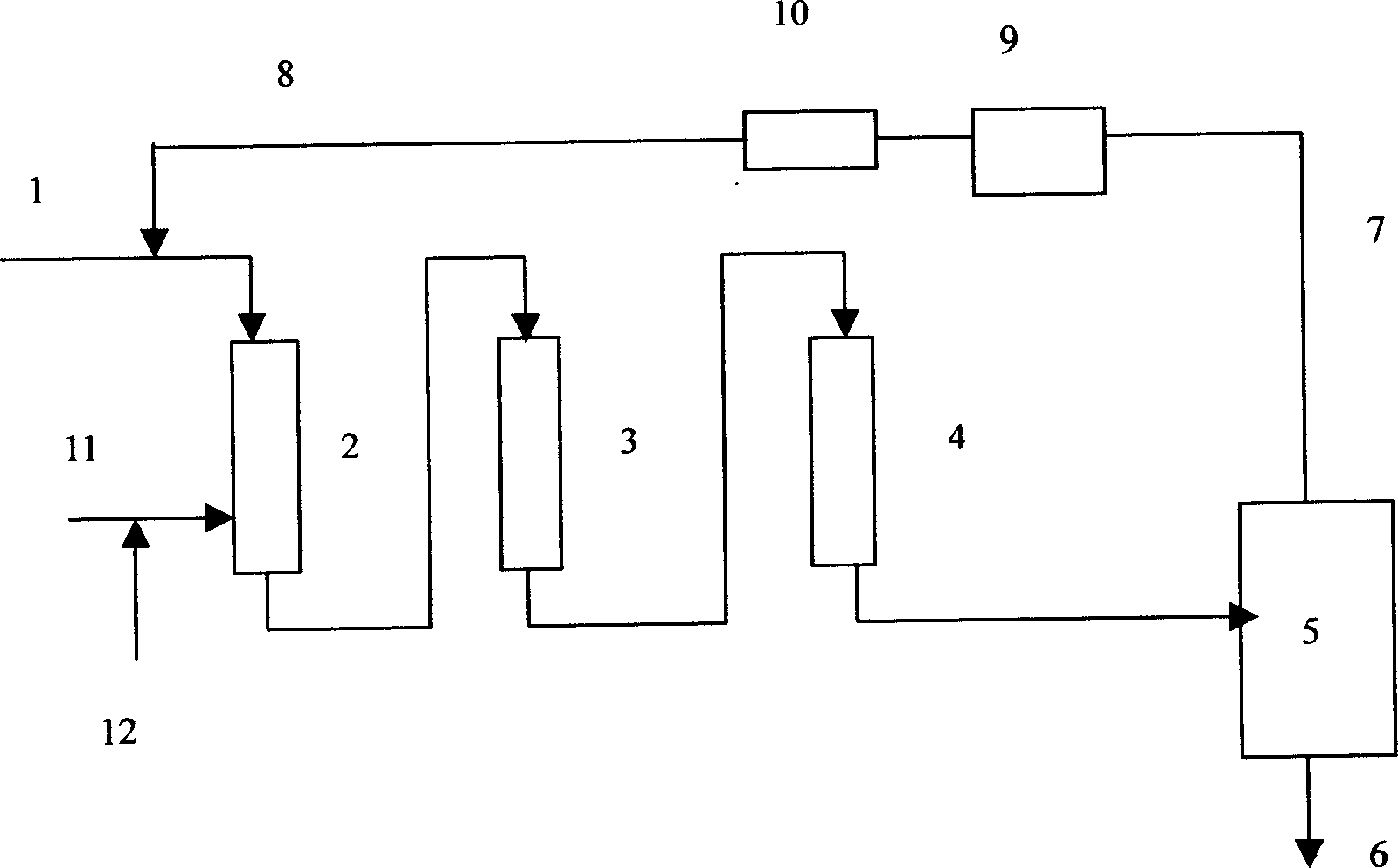

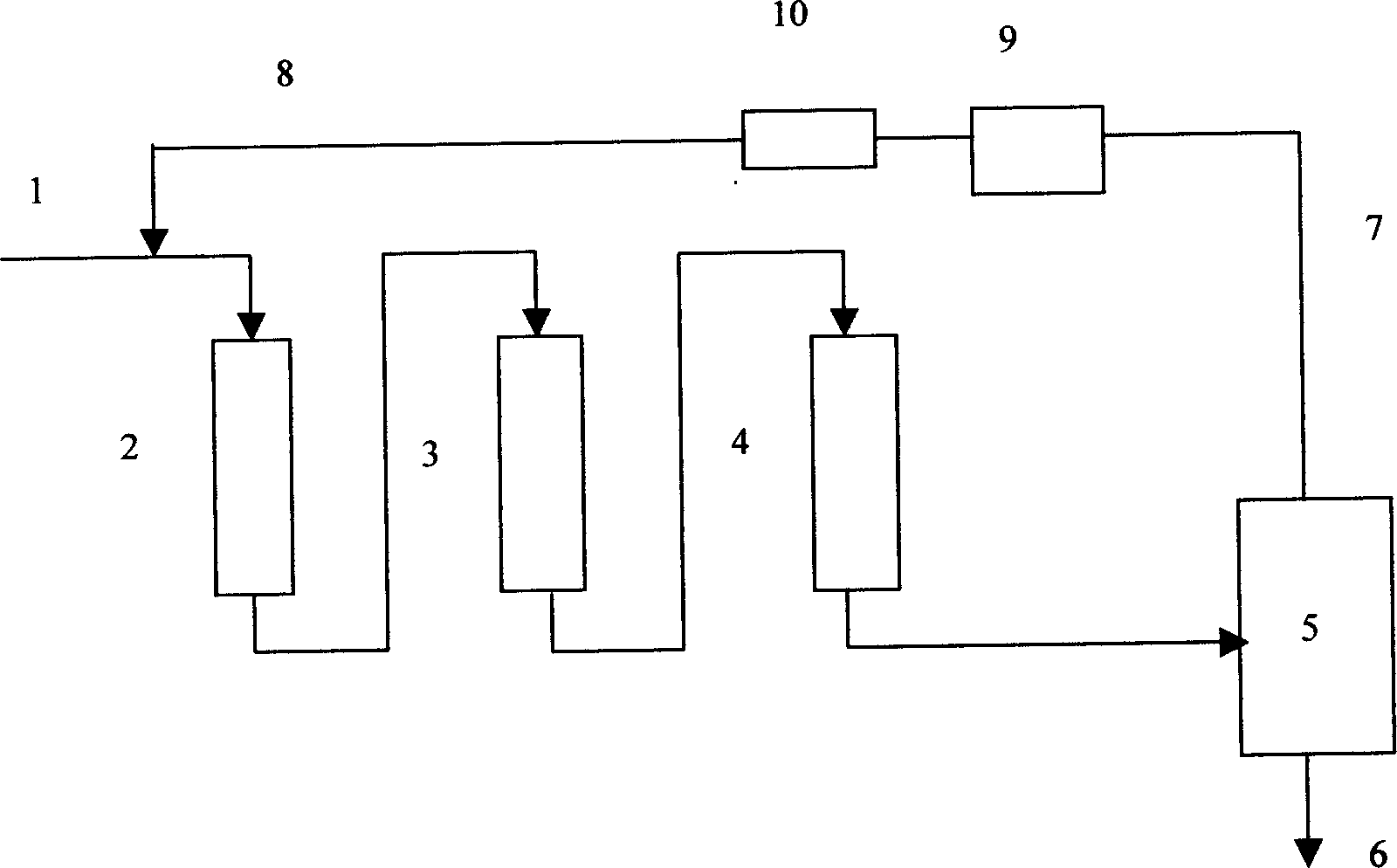

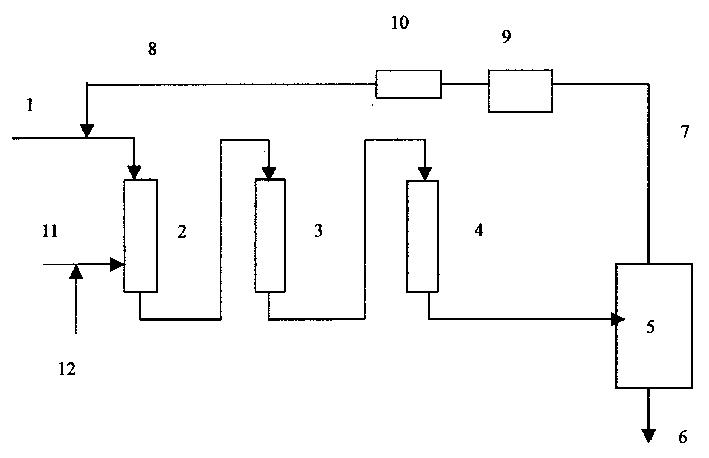

Method used

Image

Examples

Embodiment 1-3

[0016] In this embodiment, taking residual oil fixed-bed hydrogenation as an example, the test of the present invention is carried out on a pilot scale residual oil hydrotreating device. The residual oil fixed bed hydrogenation catalysts used in the test are CEN, FZC series heavy and residual oil hydrogenation demetallization catalysts produced by Fushun High-tech Development Zone, ZTN and ZTS series heavy, Hydrodenitrogenation and desulfurization catalysts for residual oil. The sequence of catalyst loading is hydrodemetallization, hydrodesulfurization and hydrodenitrogenation catalysts. Hydrodemetallization, hydrodesulfurization, and hydrodenitrogenation catalysts are loaded in the first, second and third reactors respectively. The hydrodemetallization catalysts used in this test are CEN-5, CEN-6; the protective agents are CEN-2, CEN-4, FZC-16 (transitional protective agent); the hydrodesulfurization catalysts ZTS-01, ZTS-02 , ZTS-03; Hydrodenitrogenation catalyst ZTN-01. ...

Embodiment 4~6 and comparative example 2

[0026] This embodiment and comparative example are used to investigate the equilibrium deactivation of the catalyst, and the raw material oil, catalyst and reaction conditions used are the same as those in Examples 1-3. The target operation is to meet the properties of hydrogenated atmospheric residue: S not more than 0.45w%, N not more than 0.15w%, CCR not more than 4.0w%, and Ni+V not more than 15.0μg / g. The test results are shown in Table-4.

[0027] Example

[0028] It can be seen from Table-4 that the bed pressure drop and reaction temperature of the desulfurization and denitrification catalyst bed of the present invention increase less than that of the prior art with the prolongation of operating time. What is more obvious is that the pressure drop and temperature increase of the desulfurization catalyst bed in the prior art are far greater than the denitrification catalyst bed, showing a trend that the deactivation rate of the desulfurization catalyst is much ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com