Vulcanized hydrogenation catalyst, and preparation method and application thereof

A hydrogenation catalyst and vulcanization-type technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of uneven dispersion of active components, long vulcanization time, toxicity, etc., to avoid Formation of chemical bonds, saving start-up time, and simple technical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

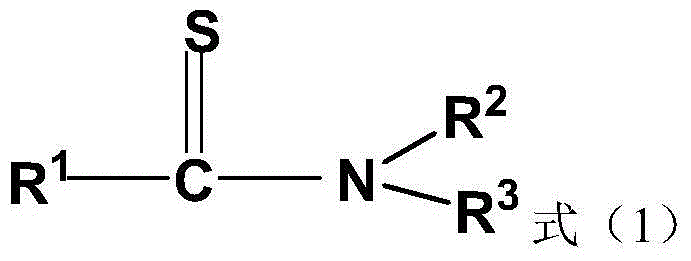

[0022] The present invention provides a kind of preparation method of single metal vulcanization type hydrogenation catalyst, and this method comprises the following steps:

[0023] (1) The dispersant is contacted with solution A containing a VIB group metal salt and a sulfur source, the solution A is acidic, the dispersant is a water-soluble organic solvent with a boiling point of 15-90° C., and the sulfur source can be Sulfur-containing substances hydrolyzed under acidic conditions at 50-100°C;

[0024] (2) Contacting the product obtained in step (1) with the catalyst carrier at 60-150° C. for 5-30 hours under airtight conditions;

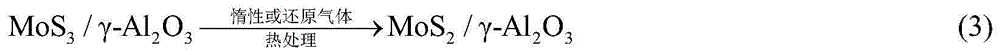

[0025] (3) Calcining the solid material obtained after contacting in step (2) in an inert or reducing atmosphere.

[0026] According to the present invention, preferably, the VIB group metal is molybdenum or tungsten, the VIB group metal salt is sodium molybdate and / or sodium tungstate, and the concentration of the VIB group metal salt in soluti...

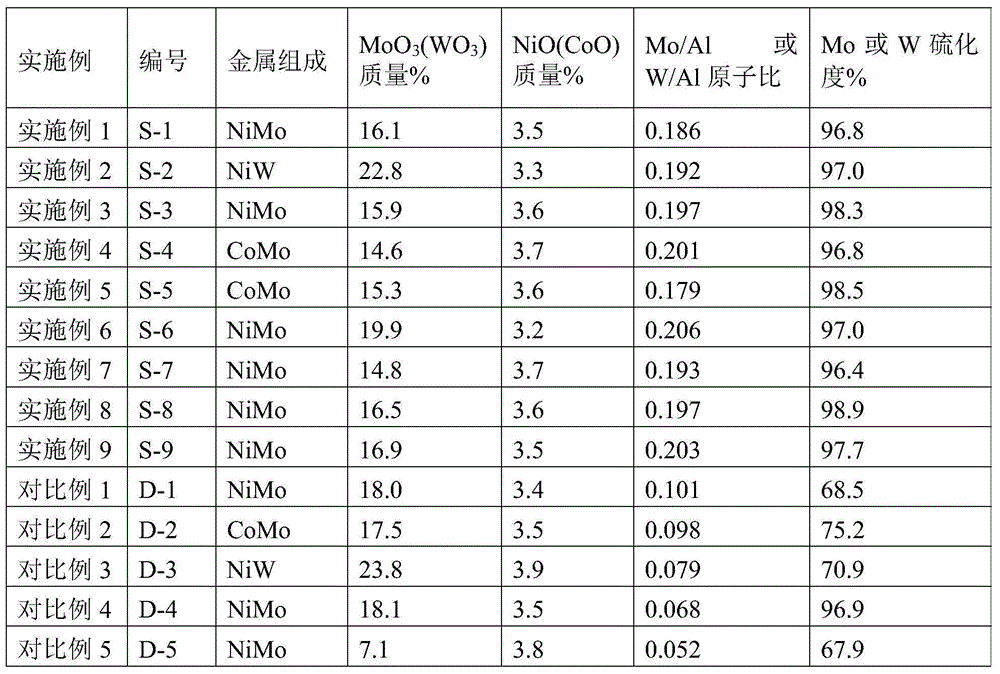

Embodiment 1

[0063] Prepare 40 mL of a solution containing 0.15 mol / L sodium molybdate and 0.45 mol / L thioacetamide, and add 4.0 mL of 2.4 mol / L hydrochloric acid dropwise during stirring to obtain solution A with a pH value of 5.0;

[0064] Measure 20mL of absolute ethanol, and add the absolute ethanol dropwise to solution A at a rate of 1mL / min while stirring continuously to form solution B;

[0065] Transfer solution B to 4.0g of γ-Al with a diameter of 2-5mm 2 o 3 Then put the autoclave into a rotary oven (100rpm rotating speed) and contact it at 85°C for 24h, then filter the suspension, wash it with water, dry it at room temperature, and put it under H2O at 500°C. 2 Calcined in the atmosphere for 4h to obtain the single metal sulfide catalyst MoS 2 / γ-Al 2 o 3 .

[0066] Prepare a nickel nitrate solution containing 2.6g of nickel nitrate and about 15mL, and take 4.5mL of it to impregnate the above-mentioned sulfurized catalyst MoS 2 / γ-Al 2 o 3 , air-dried at room temperature,...

Embodiment 2

[0069] Prepare 30 mL of a solution containing 0.20 mol / L sodium tungstate and 0.60 mol / L thioacetamide, and add 4.5 mL of 2.4 mol / L hydrochloric acid dropwise during stirring to obtain solution A with a pH value of 4.5;

[0070] Then measure 30 mL of absolute ethanol, and add the absolute ethanol dropwise to solution A at a rate of 1 mL / min while stirring continuously to form solution B;

[0071] Transfer solution B to 4.0g of γ-Al with a diameter of 2-5mm 2 o 3 granules in an autoclave, and then placed the autoclave in a rotary oven (rotating speed: 80rpm) for 24 hours at 85°C, then filtered the suspension, washed it with water, and vacuum-dried it, and placed it at 500°C in H 2 Calcined in the atmosphere for 4h, the monometallic sulfurized catalyst WS was obtained 2 / γ-Al 2 o 3 .

[0072] Prepare about 15mL of nickel acetate solution containing 1.6g of nickel acetate, and take 4.0mL of it for impregnating the above vulcanized catalyst WS 2 / γ-Al 2 o 3 , air-dried at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com