System and method of preparing paraxylene by alcohol/ether conversion

A technology for para-xylene and xylene, which is applied in the field of alcohol/ether conversion to prepare para-xylene, can solve problems such as economic impact, and achieve the effects of reducing investment, saving energy consumption, and shortening the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

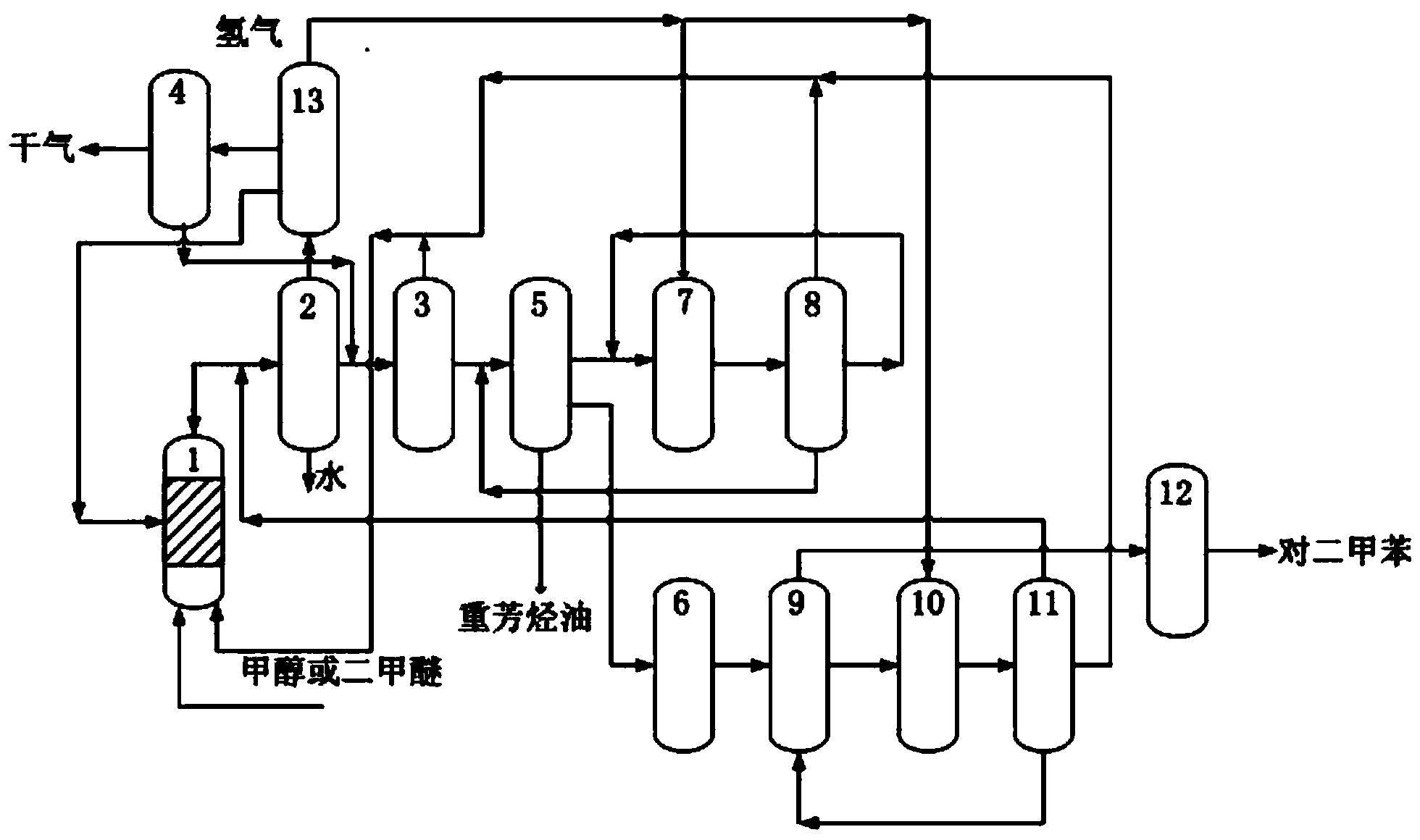

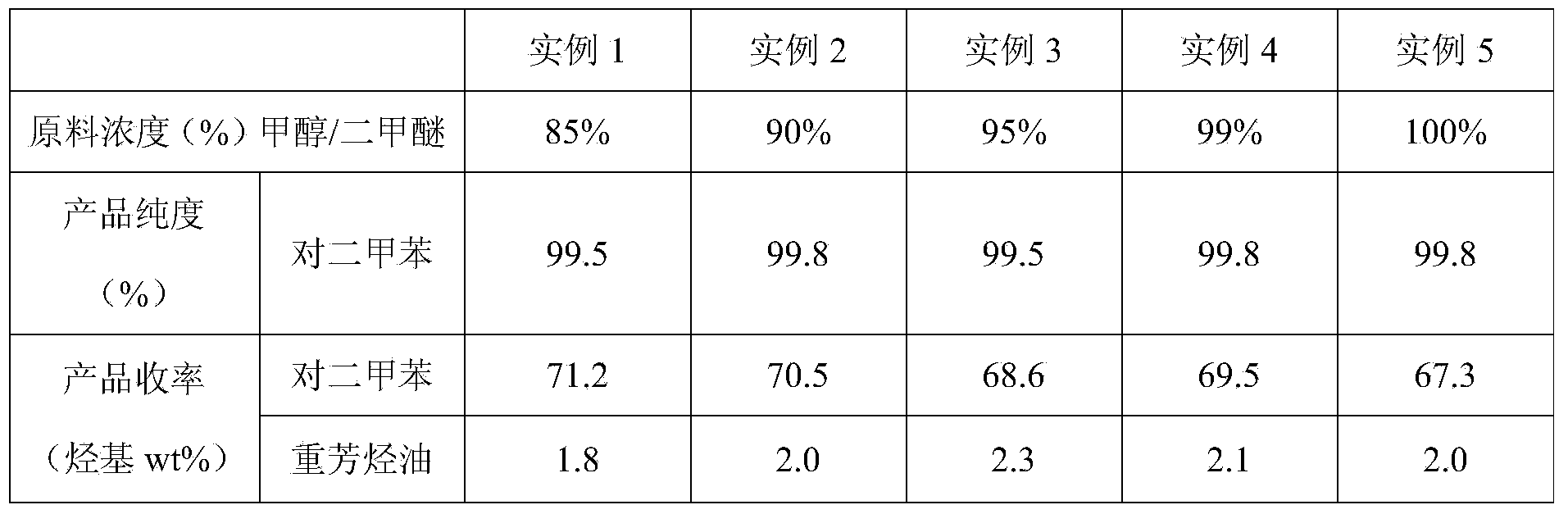

[0050] The raw material is methanol with a purity of 85% (mass fraction) (the rest is water). After entering the alcohol / ether aromatization reaction system 1, a gas phase is generated under the action of a catalyst, water, non-aromatic hydrocarbons, benzene, toluene, C 8 Aromatics, C 9 Aromatics, C 10 Aromatics and other oil phase heavy aromatics and other oil phase components, the reacted product materials enter the gas-liquid-liquid three-phase separation device 2 to be separated into gas phase, water phase and oil phase products.

[0051] The gas phase product from the gas-liquid-liquid three-phase separation device 2 is separated into C 2 The above hydrocarbons, dry gas and hydrogen. where C 2 The above hydrocarbons enter alcohol / ether aromatization reaction system 1 as reactants, and a part of hydrogen enters toluene, C 9 Methyl aromatics, C 10 The disproportionation reaction device 7 of methyl aromatics, another part of hydrogen enters the xylene isomerization devi...

Embodiment 2

[0056] The raw material is methanol with a purity of 90% (mass fraction) (the rest is water). After entering the alcohol / ether aromatization reaction system 1, it will generate a gas phase under the action of a catalyst, water, non-aromatic hydrocarbons, benzene, toluene, C 8 Aromatics, C 9 Aromatics, C 10 Aromatics and other oil phase heavy aromatics and other oil phase components, the reacted product materials enter the gas-liquid-liquid three-phase separation device 2 to be separated into gas phase, water phase and oil phase products.

[0057] The gas phase product from the gas-liquid-liquid three-phase separation device 2 is separated into C 2 The above hydrocarbons, dry gas and hydrogen. where C 2 The above hydrocarbons enter alcohol / ether aromatization reaction system 1 as reactants, and a part of hydrogen enters toluene, C 9 Methyl aromatics, C 10 The disproportionation reaction device 7 of methyl aromatics, another part of hydrogen enters the xylene isomerization ...

Embodiment 3

[0062] The raw material is methanol with a purity of 95% (mass fraction) (the rest is water). After entering the alcohol / ether aromatization reaction system 1, it will generate a gas phase under the action of a catalyst, water, non-aromatic hydrocarbons, benzene, toluene, C 8 Aromatics, C 9 Aromatics, C 10 Aromatics and other oil phase heavy aromatics and other oil phase components, the reacted product materials enter the gas-liquid-liquid three-phase separation device 2 to be separated into gas phase, water phase and oil phase products.

[0063] The gas phase product from the gas-liquid-liquid three-phase separation device 2 is separated into C 2 The above hydrocarbons, dry gas and hydrogen. where C 2 The above hydrocarbons enter alcohol / ether aromatization reaction system 1 as reactants, and a part of hydrogen enters toluene, C 9 Methyl aromatics, C 10 The disproportionation reaction device 7 of methyl aromatic hydrocarbons, another part of hydrogen enters the xylene is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com