Method of refining natural gas and natural gas refining system

a technology of natural gas and refining system, which is applied in the direction of liquefaction, separation process, lighting and heating apparatus, etc., can solve the problems of product quality deterioration, and achieve the effect of improving the product quality of liquefied natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]An embodiment of the present invention is described below with reference to the drawings.

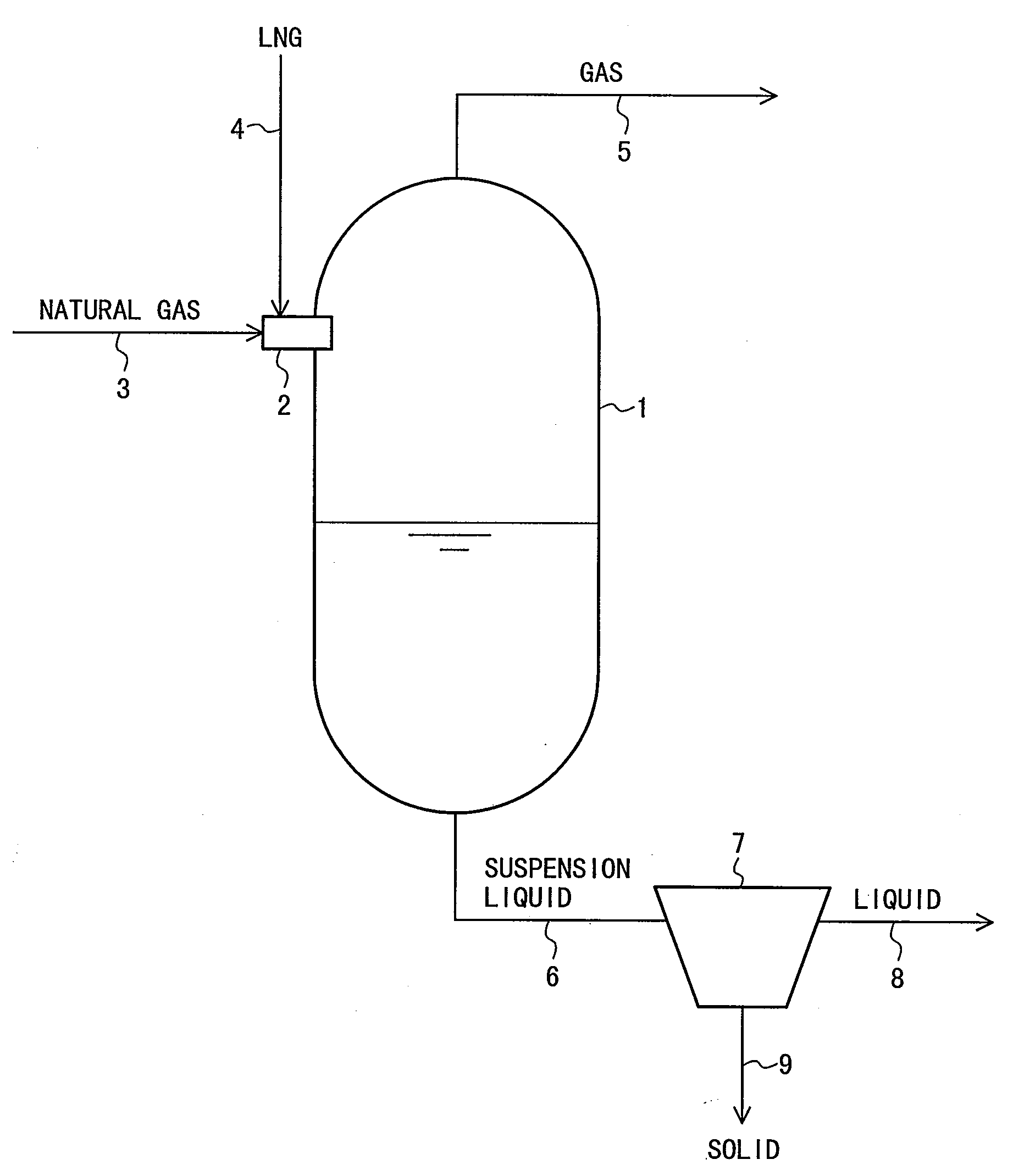

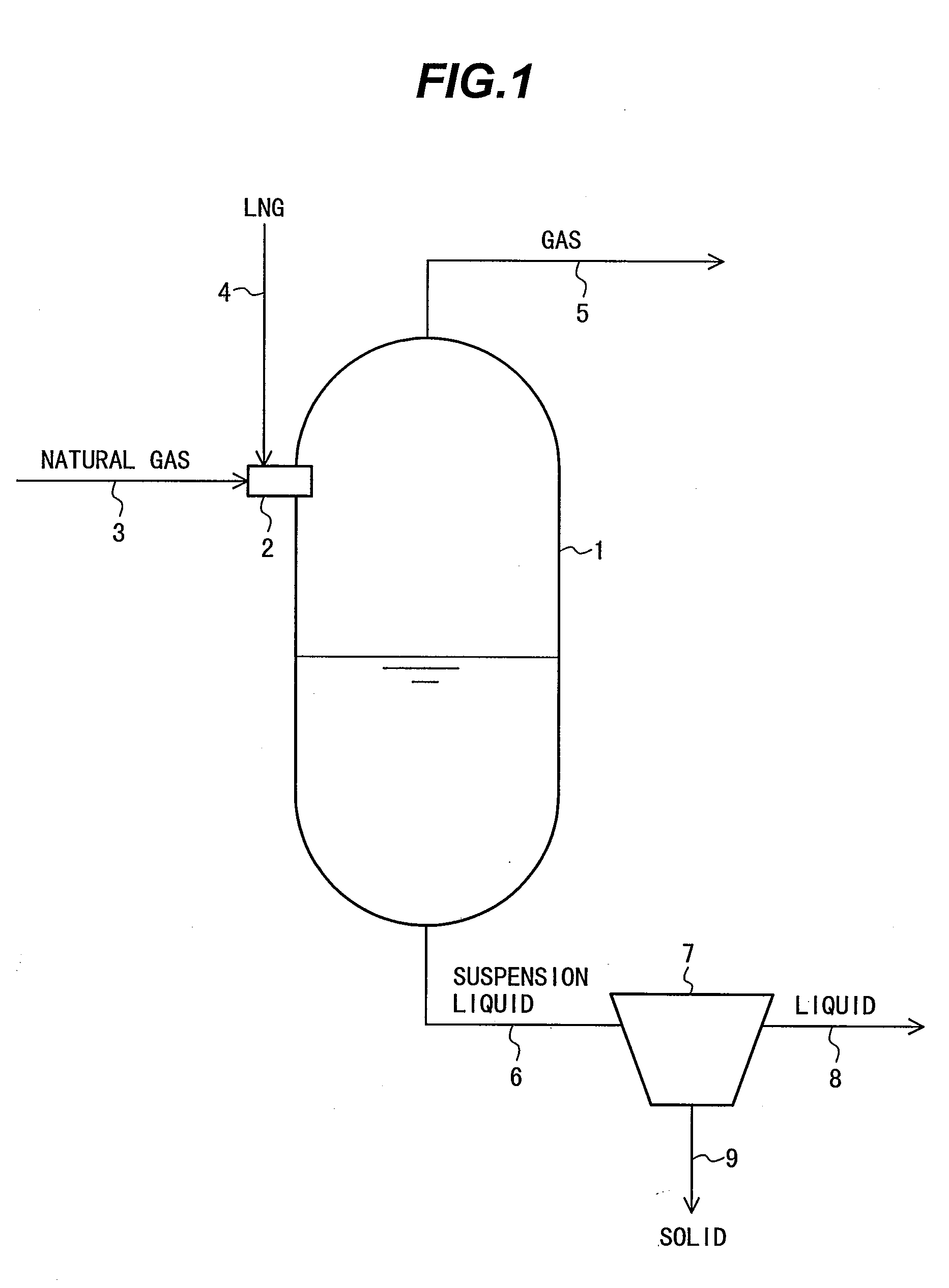

[0043]FIG. 1 is a schematic diagram illustrating a natural gas refining system according to an embodiment of the present invention.

[0044]In FIG. 1, the natural gas refining system is installed in a plant for producing liquefied natural gas (LNG) from natural gas mined in a natural gas field or in an oil field. The natural gas refining system comprises a separation tank 1 (a gas / solid separating unit), a nozzle 2 (a pressure / temperature adjusting unit) for injecting natural gas into the separation tank 1, a natural gas feed line 3, a liquefied natural gas feed line 4, a gas takeoff line 5, a suspension liquid takeoff line 6, and a cyclone 7 (a solid / liquid separating unit). The natural gas feed line 3 supplies natural gas (more specifically, natural gas just mined in a natural gas field or in an oil field, or natural gas pressurized to about 60 atm (6 MPa)) to the nozzle 2. The liquefied na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com