Iso-butane, n-butane and butylene separation and purification method

A purification method, n-butane technology, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of underutilized value and high energy consumption, and achieve the effect of reducing equipment investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

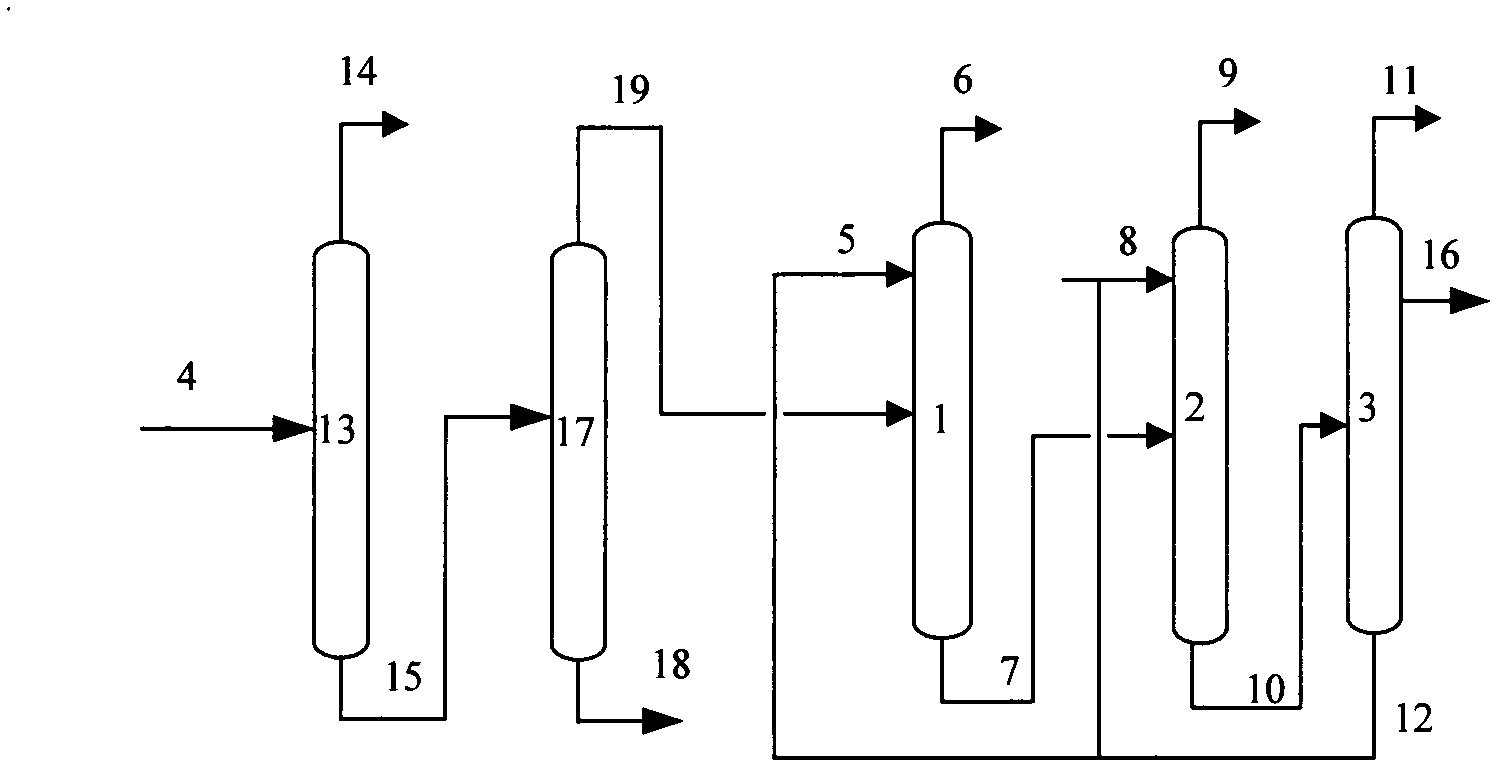

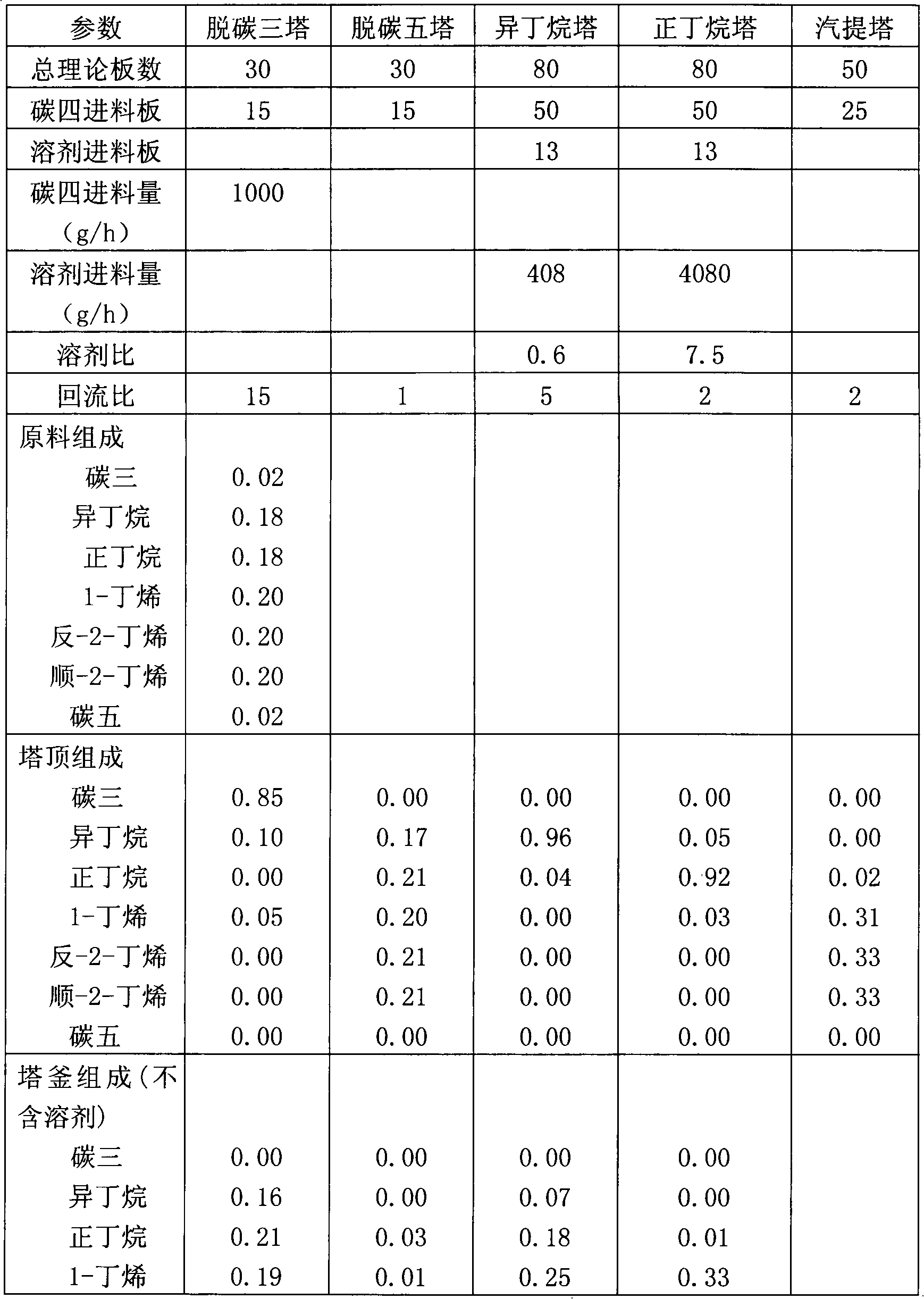

[0052] Embodiment 1 The separation and purification method of isobutane, n-butane and butene of the present invention, technological process can basically refer to attached figure 1 , the mixed carbon four raw material 4 is advanced to the third decarbonization tower 13, the carbon three components are extracted from the top of the three decarbonization towers 14, and the remaining carbon four components are extracted from the decarbonization three tower kettles and then enter the middle part of the decarbonization five tower 17 for decarbonization 18 extracted from the bottom of the C5 tower is C5 components, 19 extracted from the top of the tower is C4 components introduced into the middle of the isobutane tower 1 for feeding, and the circulating solvent 5 of the isobutane tower is fed from the upper part of the isobutane tower 1 The top of the isobutane tower 1 tower obtains isobutane 6, and the extraction product 7 of the tower kettle of the isobutane tower 1 directly ente...

Embodiment 2

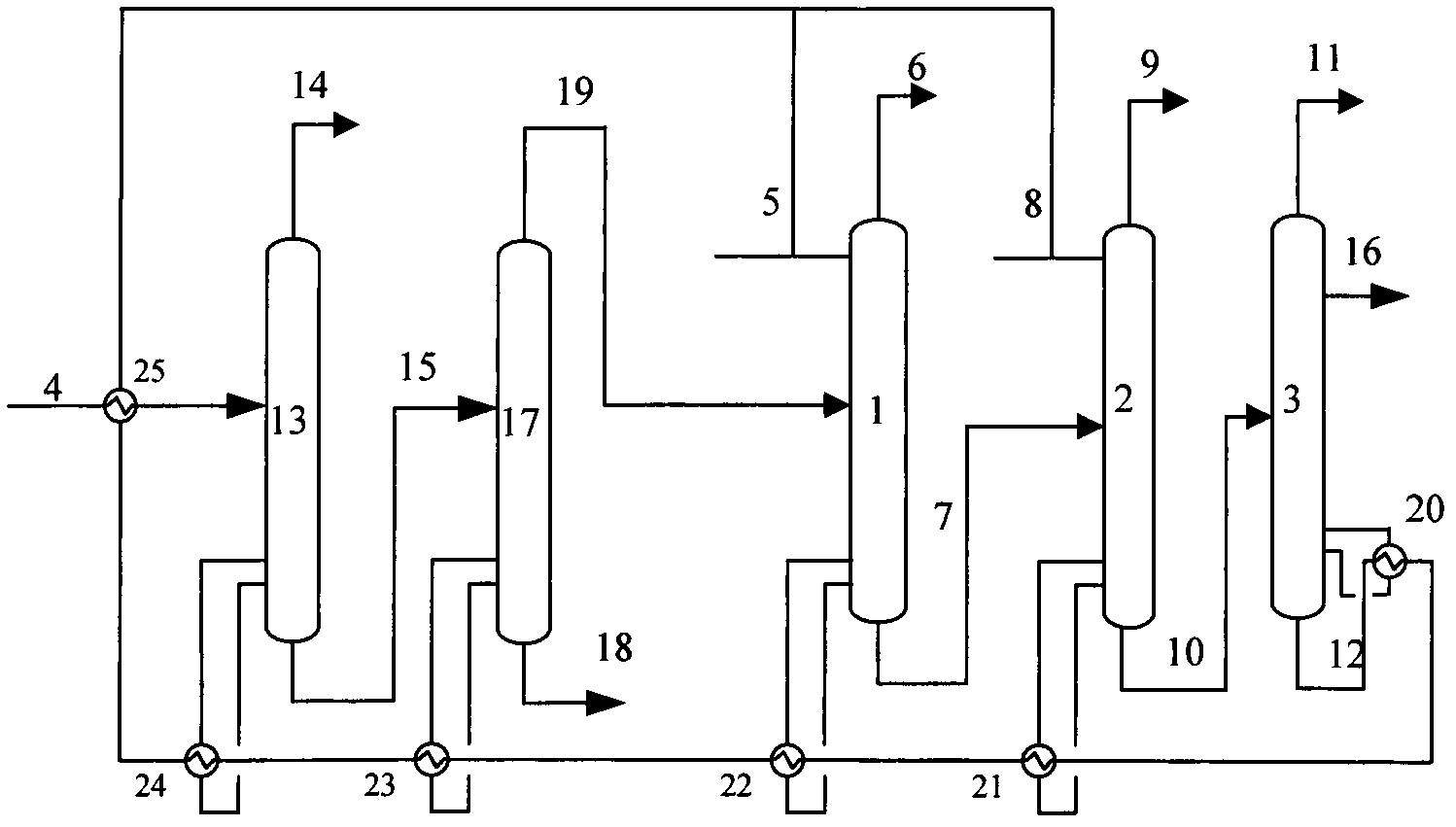

[0053] The separation and purification method of embodiment 2 isobutane, n-butane and butene, process flow sheet can refer to Figure 1-2 , the mixed carbon four contains more carbon five components, and the decarbonization five towers are added after the three decarbonization towers, the mixed carbon four raw materials 4 advanced decarbonization three towers 13, and the carbon three components are extracted from the top of the decarbonization three towers Out of 14, mixed carbon four 15 is extracted from the decarburization three tower kettle and then enters the de-C5 tower 17, carbon five component 18 is extracted from the carbon five tower kettle, and mixed carbon four 19 is extracted from the top of the tower and enters the middle part of the isobutane tower 1 Material, the circulating solvent 5 of the isobutane tower is fed from the top of the isobutane tower 1, and the top of the isobutane tower 1 obtains isobutane 6, and the extraction product 7 of the isobutane tower 1 i...

Embodiment 3

[0058] Example 3 The separation and purification method of isobutane, n-butane and butene, the isobutane can be extracted from the top of the tower and then introduced into the isobutane refining tower, refer to the attached Figure 1-2 , using acetonitrile and water as a solvent, the content of acetonitrile in the mixture is 1-99%, the purity of the obtained isobutane is 96%, the purity of n-butane is 87.3%, and the purity of n-butene is 97.5%. Solvent enters stripping tower intermediate reboiler, isobutane tower intermediate reboiler, n-butane tower intermediate reboiler, decarburization five tower intermediate reboiler, decarburization three tower intermediate reboiler, raw material preheater , the energy consumption is reduced from 1.3 tons of steam / ton of carbon four to 1.0 tons of steam / ton of carbon four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com