Alkylation reaction technique catalyzed by ion liquid and reactor apparatus

A technology of ionic liquids and reactors, applied in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve problems such as high circulation ratio and difficult separation, and achieve the goal of increasing reaction rate, restoring catalytic activity, and simple separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

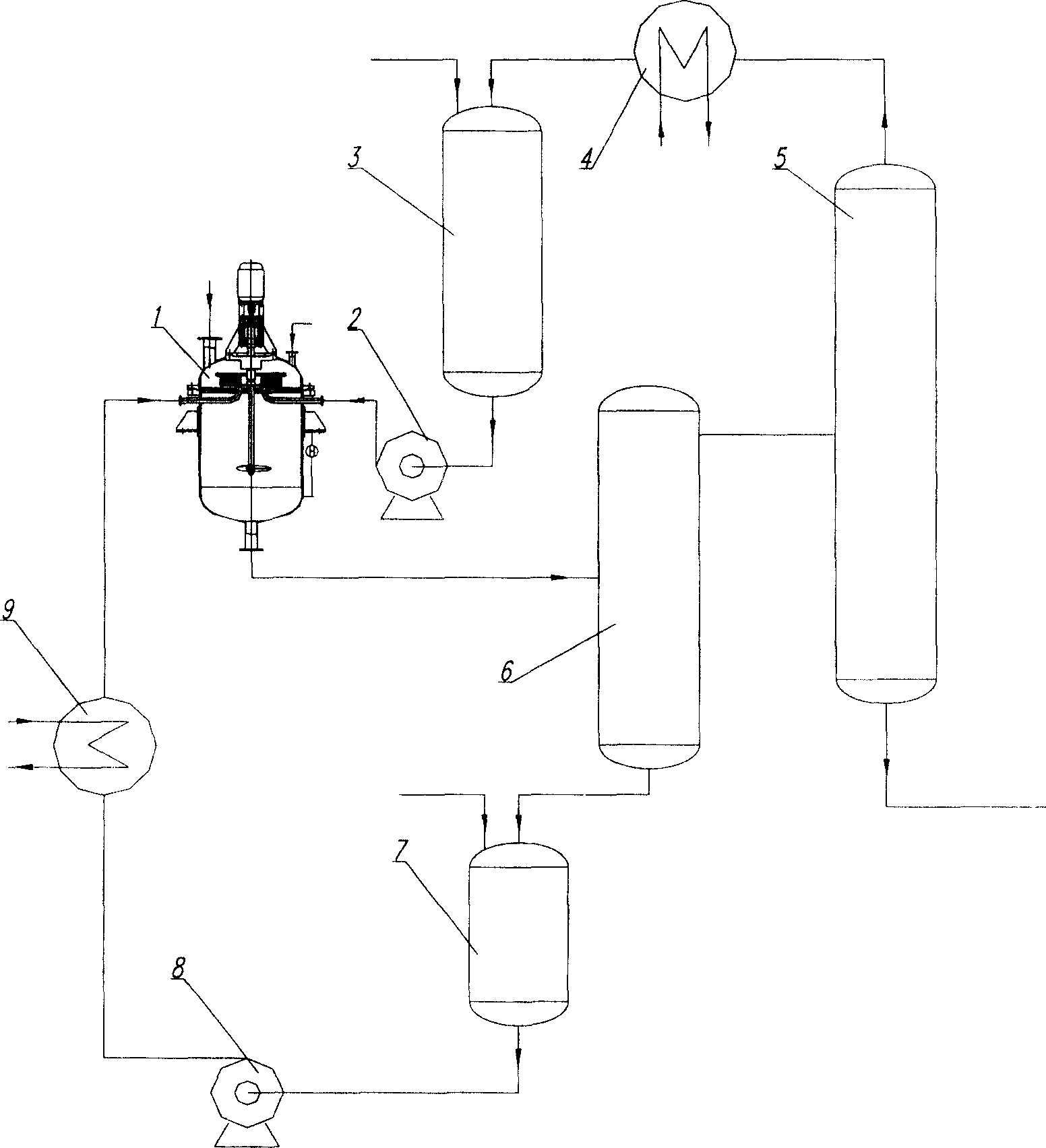

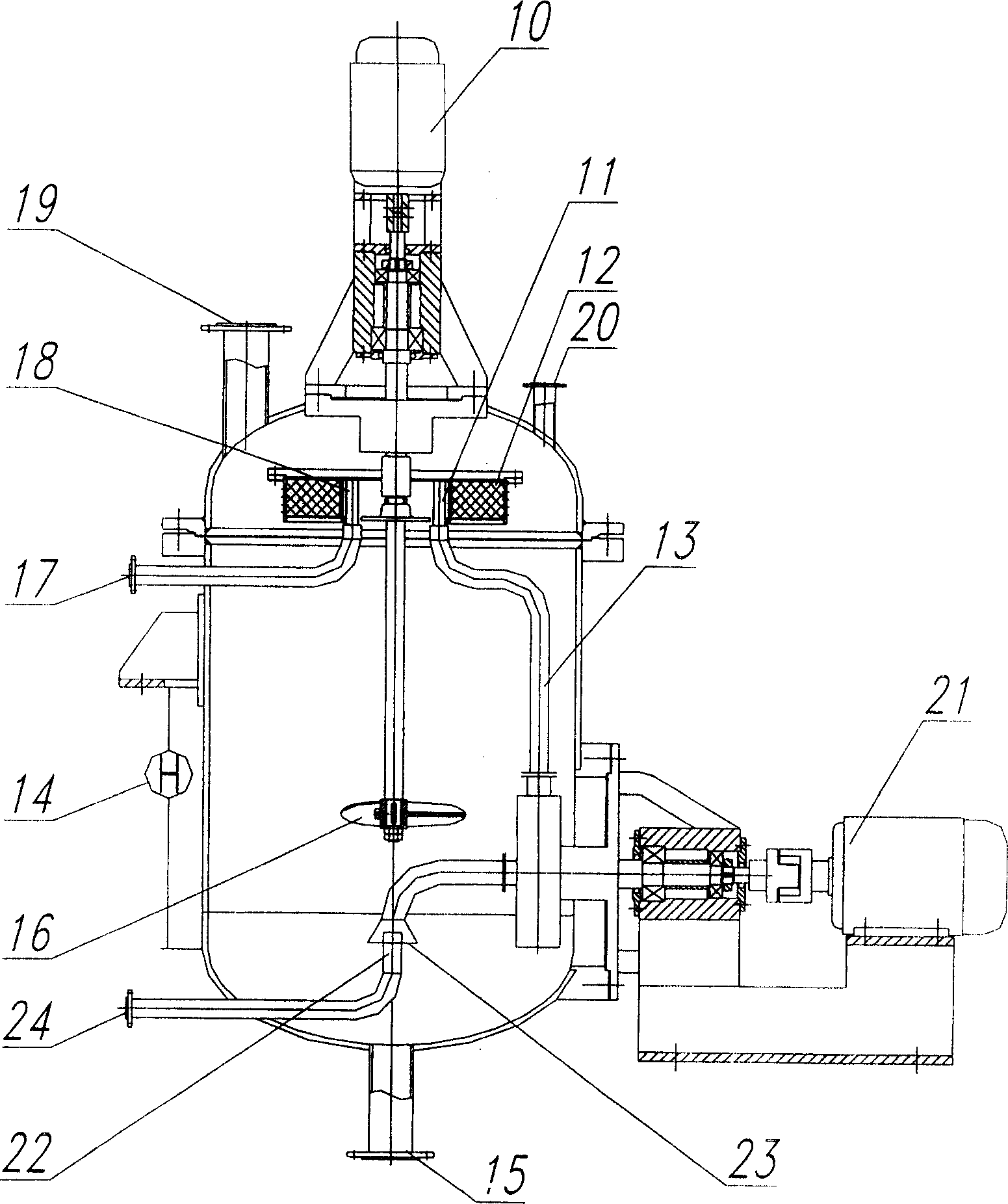

[0029] Example 1: Press figure 1 The scheme shown performs an acyclic alkylation reaction. The reaction system is pressurized to 0.5 MPa with nitrogen, and the mixed raw materials of isobutane and 2-butene, 1-butene and isobutene in the alkene tank 3 are passed through the alkene feed pipe 17 and the alkene pump 2. The alkene nozzle 18 is sprayed into the rotating packed bed, the volume flow rate of the raw material alkanes is 80 L / h, and the molar ratio of the alkanes in the raw materials is 150:1. At the same time, the ionic liquid in the catalyst tank 7 is sprayed into the rotating bed through the catalyst feed pipe 13 and the catalyst nozzle 11, and the feed rate (volume) ratio of the ionic liquid and the reaction raw materials is 0.5. The ionic liquid and the reaction raw materials are mixed and reacted in the rotating bed packing layer, and then thrown out and collected into the reactor. When the volume of the material in the reactor reaches a certain amount, the outlet...

Embodiment 2

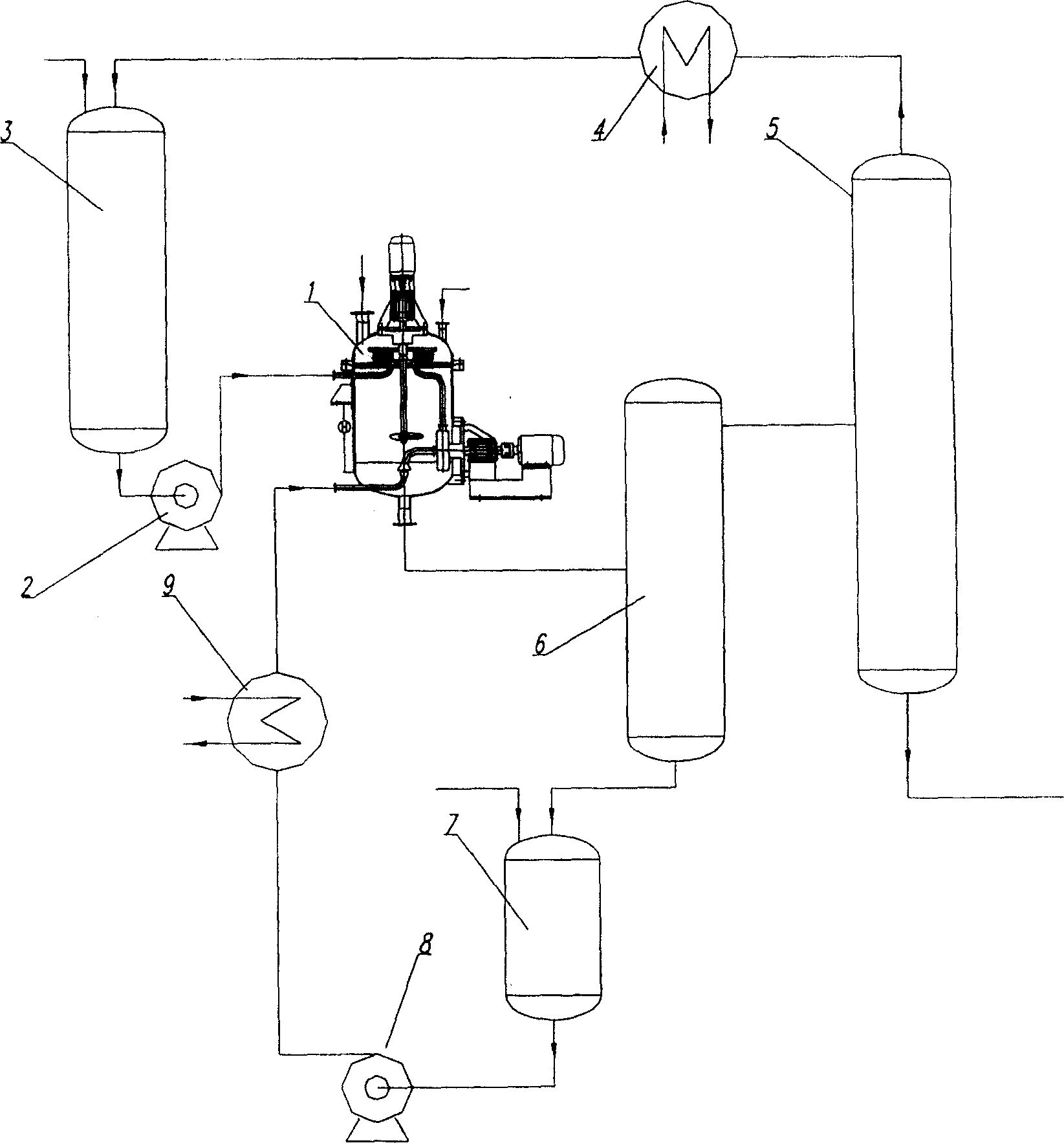

[0030] Example 2: Press figure 2 The process shown carries out the alkylation reaction in the circulation of materials. Use nitrogen to pressurize the reaction system to 0.4MPa, inject the ionic liquid in the catalyst tank 7 into the reactor through the feeding port 19, and turn on the circulation pump 21 after reaching a certain liquid level, and the alkene pump 2 will pump the alkene tank 3 The mixed feedstock of isobutane and 2-butene, 1-butene and isobutene is sprayed into the rotary bed through alkene feed pipe 17 and alkene nozzle 18, the volume flow rate of raw material is 80L / h, ionic liquid and The feed rate (volume) ratio of the reaction raw materials was 0.25:1. The ionic liquid and the reaction raw materials are mixed and reacted in the packing layer. After being thrown out and collected in the reactor, part of the material in the reactor is sucked into the conical mixer 22 by the circulation pump, and mixed with the ionic liquid from the catalyst tank 7 in the ...

Embodiment 3

[0031] Embodiment 3: press figure 2 The shown process carries out the external circulation type alkylation reaction. Use nitrogen to pressurize the reaction system to 0.5 MPa, inject the ionic liquid in the catalyst tank 7 into the reactor through the feeding port 19, and turn on the circulation pump 21 when a certain liquid level is reached, and the alkene pump 2 will transfer the alkene tank 3 The mixed feedstock of isobutane and 2-butene, 1-butene and isobutene is sprayed into the rotary bed through alkene feed pipe 17 and alkene nozzle 18, the volume flow rate of raw material is 80L / h, ionic liquid and The reaction raw material feed rate (volume) ratio was 0.25. The ionic liquid and the reaction raw materials are mixed and reacted in the packing layer. After being thrown out and collected in the reactor, part of the material in the reactor is sucked into the conical mixer 22 by the circulation pump, and mixed with the ionic liquid from the ion tank in the conical mixer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com