Gasoline hydrodesulfurization method

A gasoline hydrogenation and gasoline technology, which is applied in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of generating mercaptan sulfur, etc., and achieve the advantages of low mercaptan sulfur content, less olefin saturation, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

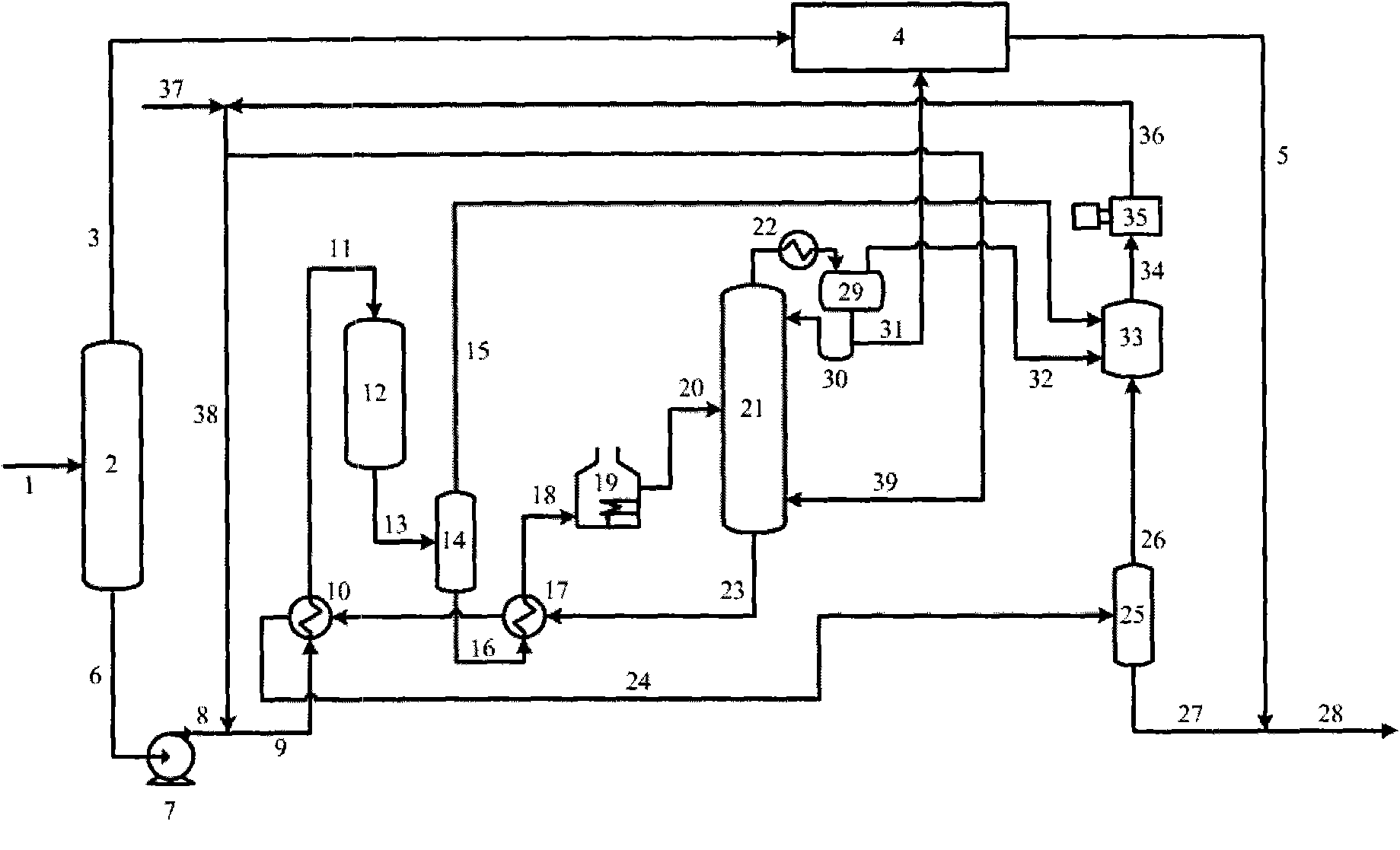

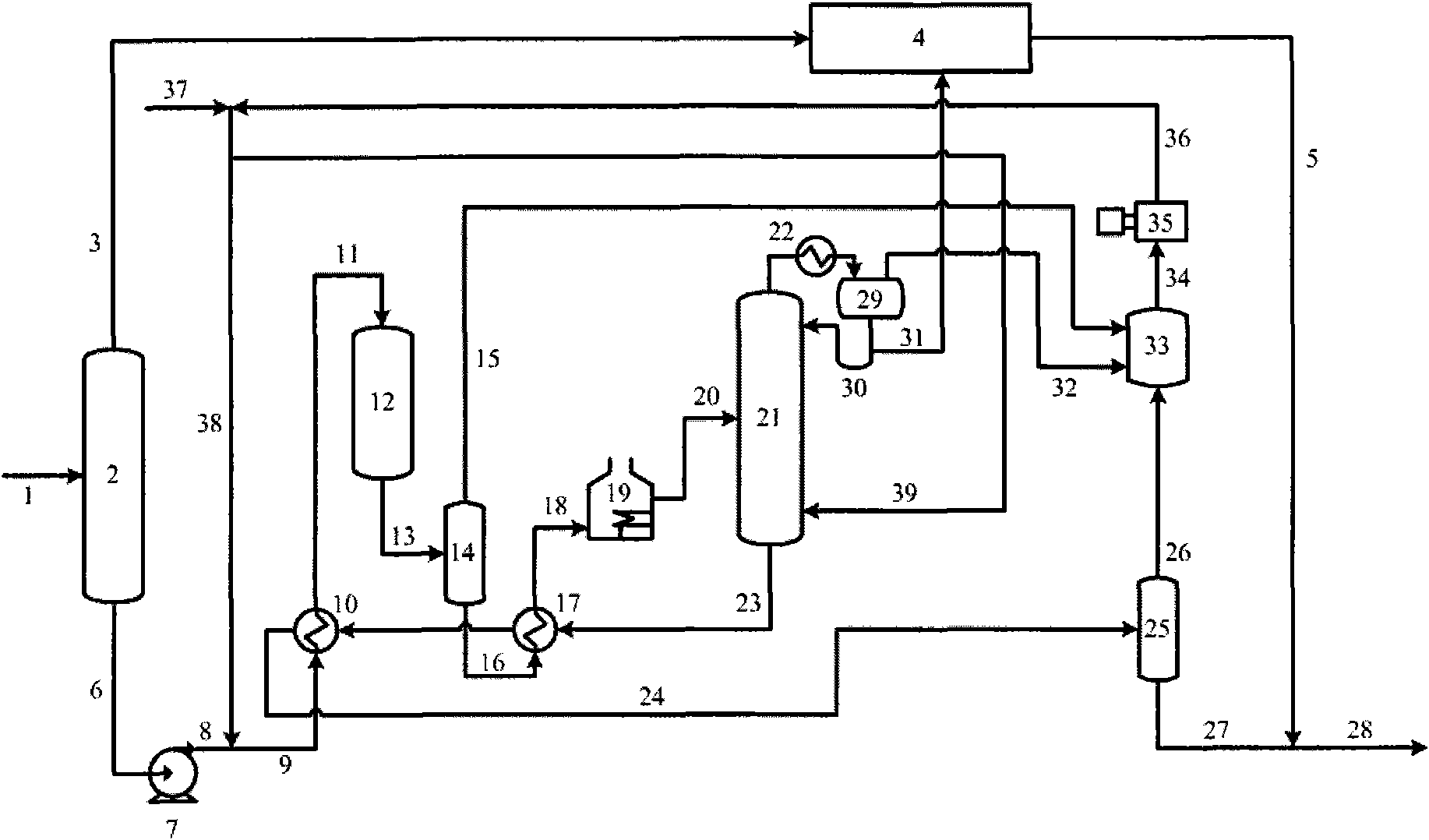

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the preferred selective desulfurization catalyst is as follows.

[0036] The carrier is obtained by mixing alumina hydrate and auxiliary agents, drying, and roasting in the air for 2 to 6 hours. The carrier is immersed in the prepared aqueous solution containing cobalt and / or nickel compound, molybdenum and / or tungsten compound for 1-4 hours, dried, and calcined at 300-550°C for 2-5 hours to obtain the catalyst product.

[0037] The aqueous solution of cobalt, molybdenum, nickel and tungsten compounds can be prepared by conventional methods. Cobalt, molybdenum, nickel and tungsten compounds are selected from one or more of their soluble compounds. Wherein the molybdenum compound is preferably ammonium molybdate, and the cobalt compound is preferably one or more of cobalt nitrate, cobalt chloride, and basic cobalt carbonate. The compounds of nickel and tungsten are preferably one or more of nickel nitrate, nickel chloride, basic nickel carbona...

Embodiment 1

[0054] In this embodiment, the same raw material oil A and the same cut point of 75° C. as Comparative Example 1 were used, and the resulting light fraction (A-LCN) and heavy fraction (A-HCN) accounted for 34.7% by weight and 65.3% by weight of the raw material, respectively. The A-LCN alkali delivery and extraction unit undergoes alkali refining to remove mercaptans, A-HCN is mixed with a stream of hydrogen, enters the first hydrogenation reactor, and contacts with the dealdiene catalyst RGO-2 and the selective hydrodesulfurization catalyst C1 respectively. The diolefins and more than 80% of sulfur are removed. After separation, the liquid phase is heated by a heating furnace and enters the second hydrogenation reactor. The gas phase hydrocarbons flow upward in the upper part of the reactor under the action of the selective hydrodesulfurization catalyst C1. In the desulfurization reaction, the liquid phase hydrocarbon flows downward in the lower part of the reactor under the a...

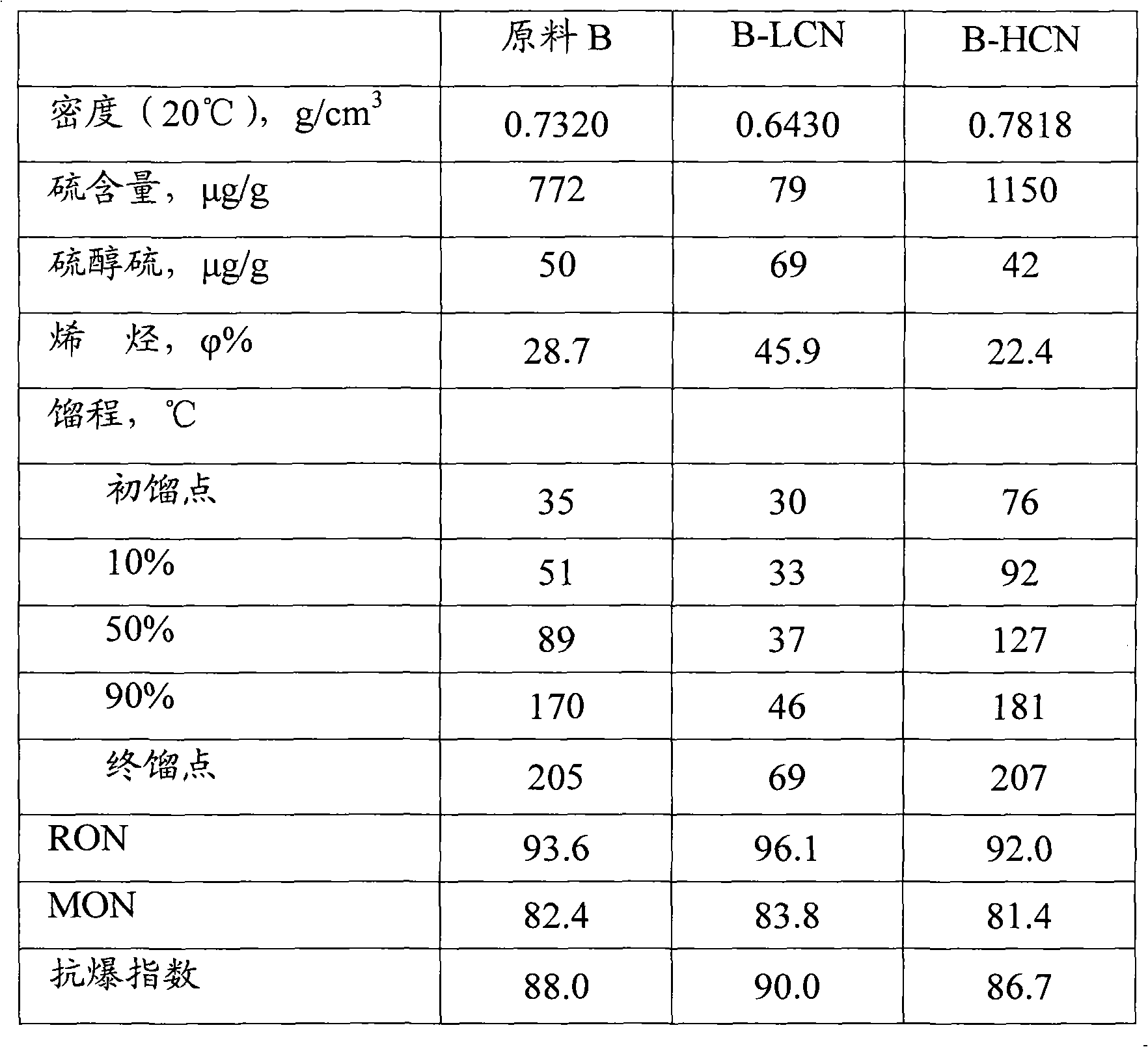

Embodiment 2

[0068] In this example, the same feed oil B and the same cut point as Comparative Example 2 were used, and the resulting light fraction (B-LCN) and heavy fraction (B-HCN) accounted for 30.0% by weight and 70.0% by weight of the raw material, respectively. The B-LCN alkali delivery and extraction unit undergoes alkali refining to remove mercaptans, B-HCN is mixed with a stream of hydrogen, enters the first hydrogenation reactor, and contacts with the dealdiene catalyst RGO-2 and the selective hydrodesulfurization catalyst C1 respectively. The diolefins and more than 80% of sulfur are removed. After separation, the liquid phase is heated by a heating furnace and enters the second hydrogenation reactor. The gas phase hydrocarbons flow upward in the upper part of the reactor under the action of the selective hydrodesulfurization catalyst C1. In the desulfurization reaction, the liquid phase hydrocarbon flows downward in the lower part of the reactor under the action of the selectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com