Liquid-phase hydrogenation refining method of aviation kerosene

A technology of aviation kerosene and refining method, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc., and can solve the adverse effects of high volume of hydrogen oil, increase of investment cost of hydrogenation reaction device, operation energy consumption, and production efficiency, etc. problems, to achieve the effect of simplifying the process flow route, good hydrofining effect and reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] use Figure 5 In the method shown, hydrogen is injected into aviation kerosene through a mixing device, and the hydrogen-carrying aviation kerosene raw material oil is sent into a tubular fixed-bed reactor (with an inner diameter of 65 mm, and a catalyst bed with a catalyst loading height of diameter ratio of 25), under the conditions shown in Table 1, contact with a catalyst with catalytic hydrogenation (commercially purchased from Sinopec Fushun Petrochemical Research Institute, brand RSS-2), the raw oil and the obtained hydrogenation product The properties are shown in Table 1.

[0069] Among them, in the liquid channel of the mixing device, the temperature is 260°C and the pressure is 2.0 MPa; relative to 100 parts by weight of raw material oil, the amount of injected hydrogen is 0.025 parts by weight (the chemical hydrogen consumption of 100 parts by weight of raw material oil is 0.02 parts by weight, under the hydrofinishing conditions shown in Table 1, the satur...

Embodiment 2

[0078] Adopt the method identical with embodiment 1 to carry out hydrogenation refining to aviation kerosene, difference is:

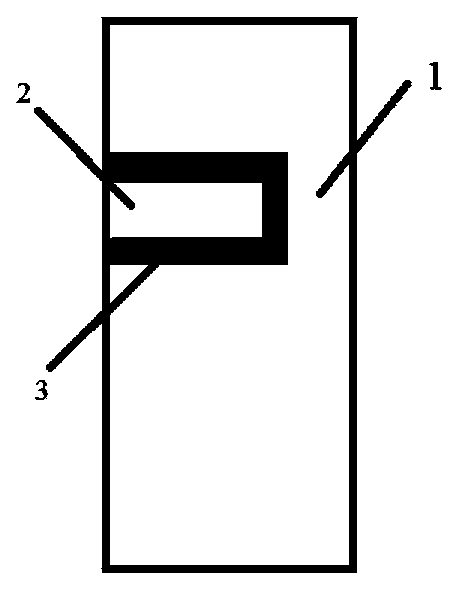

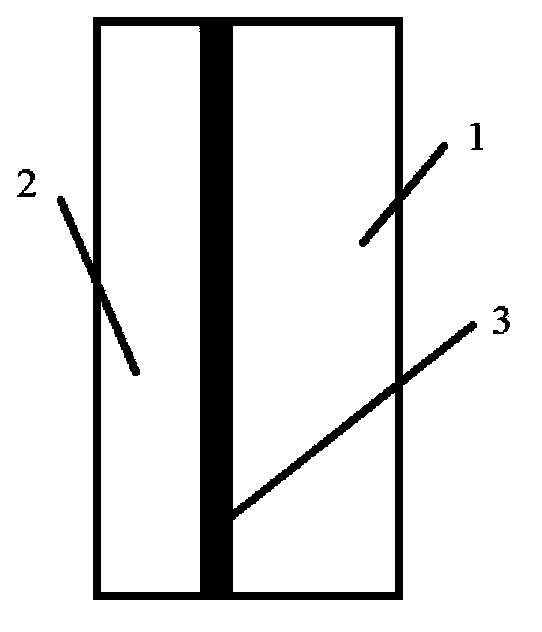

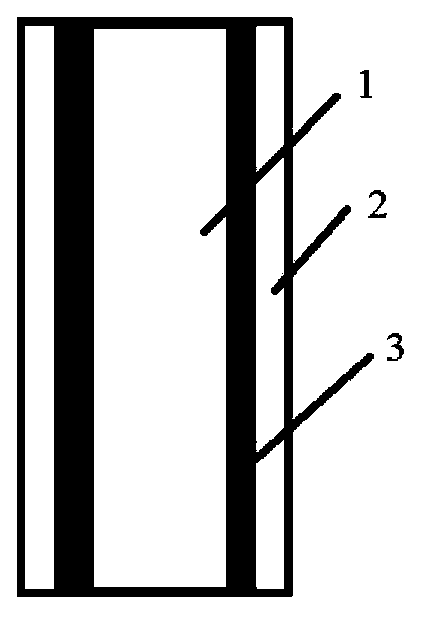

[0079] The mixing device includes a membrane tube (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd., with an outer diameter of 25.4 mm, the average pore diameter of the through holes on the substrate is 100 μm, and the average pore diameter of the through holes on the porous membrane is 250 nm) and with the pipeline A housing (with an inner diameter of 40mm) for use; the porous membrane is located on the outer wall of the membrane tube; the cross-section of the membrane tube is as follows Figure 4 As shown, there are 7 liquid channels evenly distributed, and the inner diameter of each liquid channel is 6mm; the space formed by the outer wall of the membrane tube and the inner wall of the housing is a gas channel;

[0080] In the liquid channel of the mixing device, the temperature is 260°C and the pressure is 2.0MP...

Embodiment 3

[0084] Adopt the method identical with embodiment 1 to carry out hydrogenation refining to aviation kerosene, difference is:

[0085] The mixing device includes a membrane tube (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd., with an outer diameter of 25.4 mm, the average pore diameter of the through holes on the substrate is 100 μm, and the average pore diameter of the through holes on the porous membrane is 500 nm) and the A shell (with an inner diameter of 40mm) used in conjunction with the pipe; the porous membrane is located on the inner wall of the membrane pipe, and the cross-section of the pipe is as follows: Figure 4 As shown, there are 19 liquid channels evenly distributed, and the inner diameter of each liquid channel is 3.3mm; the space formed by the outer wall of the membrane tube and the inner wall of the housing is a gas channel;

[0086] In the liquid channel of the mixing device, the temperature is 280°C and the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com