Optimal feature vector design method for carrying out reverse photolysis based on machine learning

A technology of machine learning and optimal features, applied in machine learning, neural learning methods, computer-aided design, etc., can solve the problems of complex feature vector extraction layer, lack of physical meaning, and difficult training, so as to shorten training time and simplify neural networks. network effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

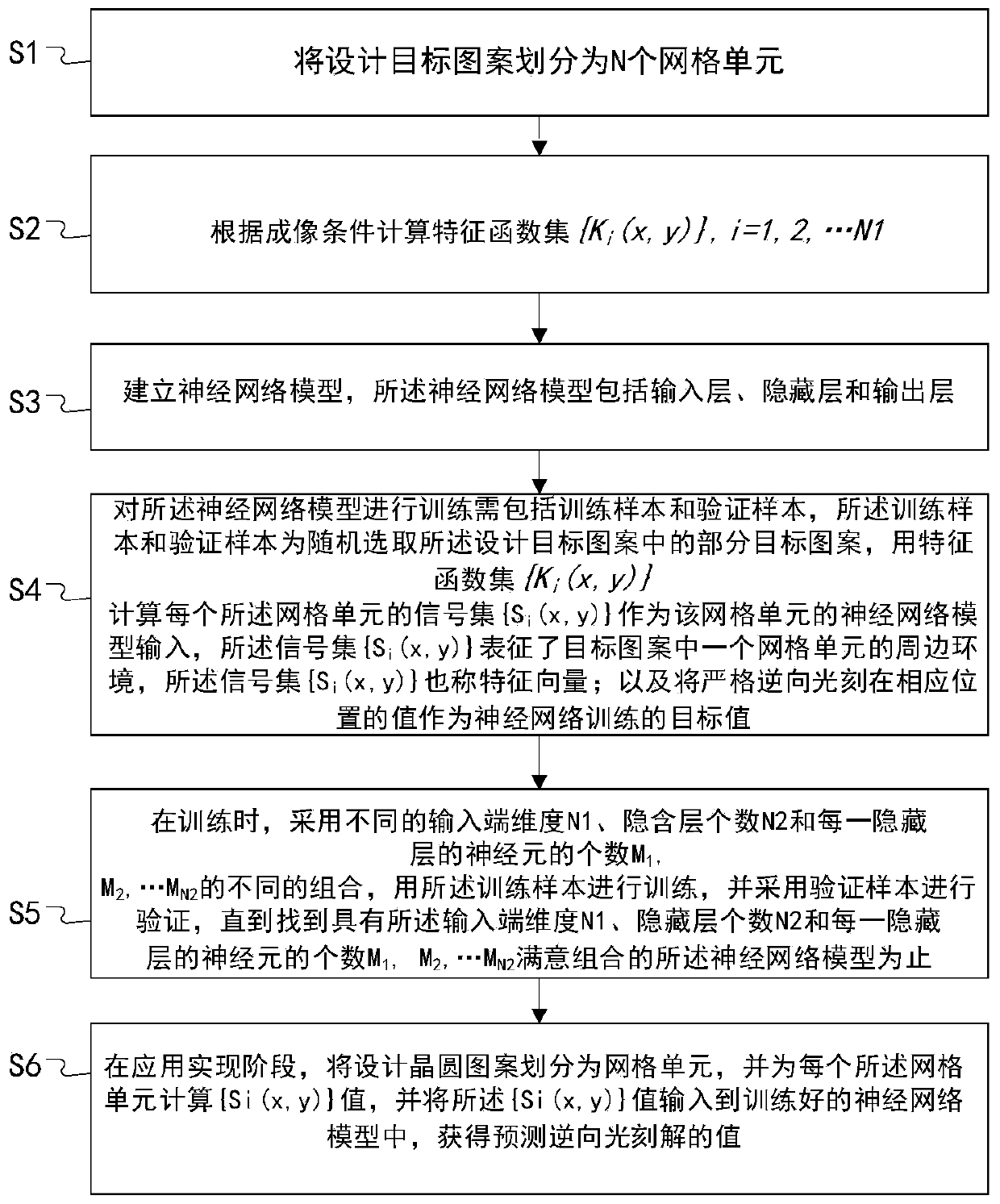

[0040] Attached below Figure 1-15 , the specific embodiment of the present invention will be further described in detail.

[0041]It should be noted that the optimal eigenvector design method for the reverse lithography solution based on machine learning in the present invention is used to predict the value of the reverse lithography solution. Among them, the value of the reverse lithography solution can be applied to reverse lithography based on machine learning, optical proximity correction (OPC) based on machine learning, hotspot detection in lithography based on machine learning, etc. The optimal eigenvector design method can be used for Computational lithography (inverse lithography, optical proximity correction, lithographic hotspot detection) for immersion lithography can also be used for computational lithography (inverse lithography, optical proximity correction, lithographic hotspot detection) for EUV lithography.

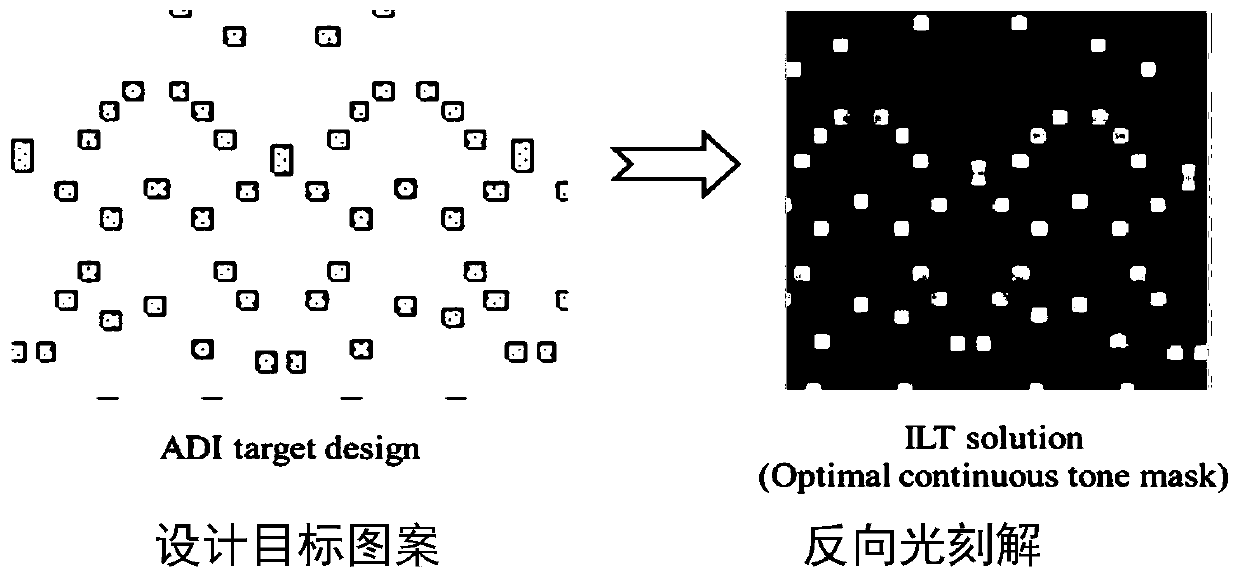

[0042] see figure 1 , figure 1 Shown is an idea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com