Rotary compressor

A rotary compressor and compressor technology, applied in the field of compressors, can solve the problems of difficult compressor design and assembly, and achieve the effect of reducing the overall height and size, and eliminating the need for rolling parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

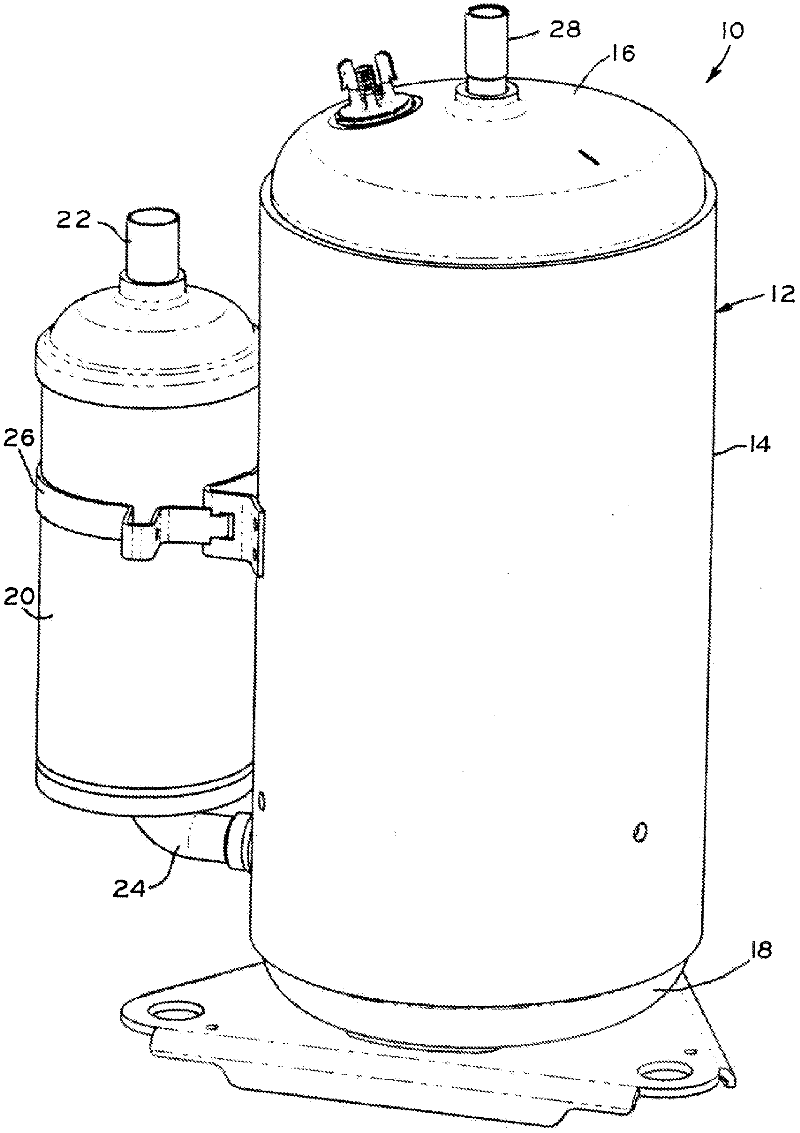

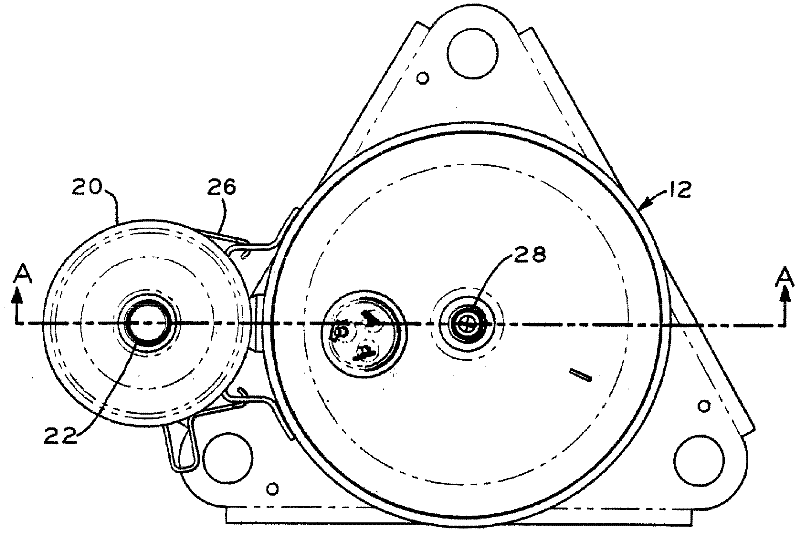

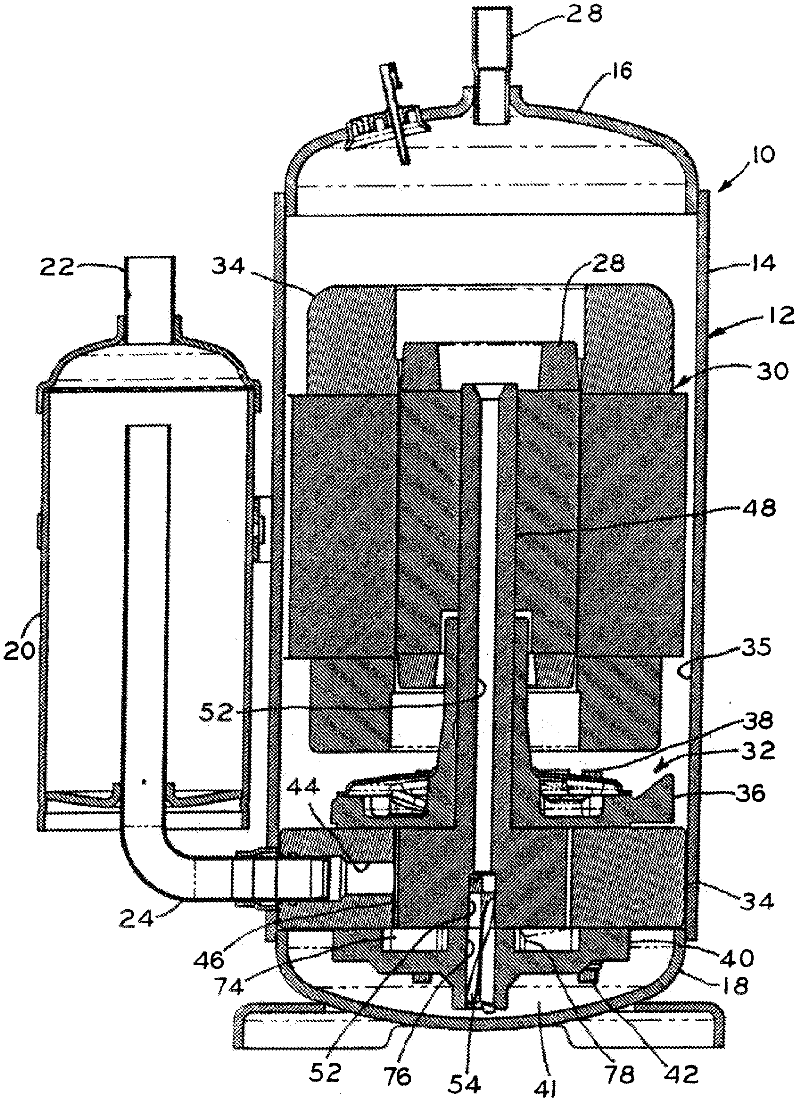

[0023] figure 1 A rotary compressor 10 forming one embodiment of the present invention is shown. Compressor 10 includes an outer hermetic casing 12 including a central portion 14 to which an upper cover 16 and a lower cover 18 are attached, for example by welding. The central portion 14 of the compressor 10 is connected by a mounting strap 26 to a conventional suction accumulator 20 having an inlet 22 and an outlet suction pipe 24 . The compressed refrigerant is discharged from the high pressure housing 12 via the discharge pipe 28 . The compressor 10 may be part of a heating circuit and / or a cooling circuit and is used to compress a working fluid such as a refrigerant such as a hydrofluorocarbon refrigerant, a chlorofluorocarbon refrigerant, a hydrochlorofluorocarbon refrigerant, or carbon dioxide refrigerant.

[0024] now go to Figure 3 to Figure 5 , a motor 30 and a compression mechanism 32 are installed in the sealed housing 12 . An oil sump 41 ( image 3 ). The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com