Corrosion-resistant sealing wax for bridge cables and anchor heads and preparation method thereof

A sealing wax and anti-corrosion technology, applied in the field of anti-corrosion sealing wax and its preparation, can solve the problems of low fluidity, poor stability of anti-corrosion grease, formation of pores, etc., and achieve the effect of enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

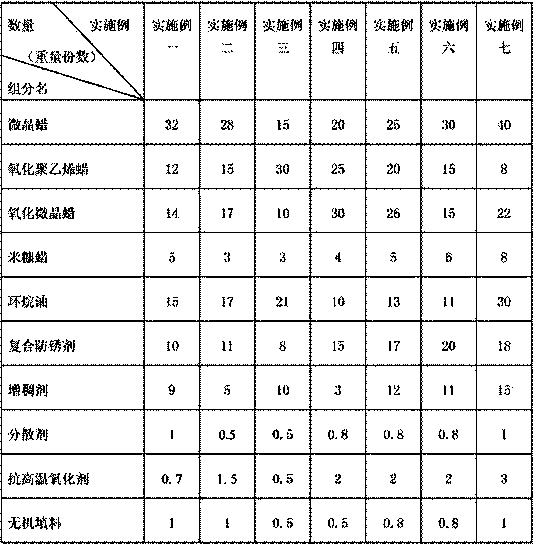

[0067] A kind of anti-corrosion sealing wax for bridge cables and anchor heads is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated in parts by weight:

[0068] No. 65 microcrystalline wax 20 weight parts, No. 85 microcrystalline wax 12 weight parts;

[0069] 12 parts by weight of oxidized polyethylene wax; 14 parts by weight of oxidized microcrystalline wax,

[0070] 5 parts by weight of rice bran wax; 15 parts by weight of KN4010 naphthenic oil,

[0071] 10 parts by weight of composite antirust agent, (including 6 parts by weight of barium petroleum sulfonate, 2 parts by weight of lanolin calcium soap, and 2 parts by weight of benzotriazole);

[0072] 9 parts by weight of thickener (including 2 parts by weight of polymethacrylate, 5 parts by weight of polyisobutylene (30000), 2 parts by weight of dibutyl phthalate);

[0073] 1 part by weight of dispersant (1 part by weight of glyceryl tristearate);

[0...

Embodiment 2

[0082] A kind of anti-corrosion sealing wax for bridge cables and anchor heads is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated in parts by weight:

[0083] 28 parts by weight of No. 90 microcrystalline wax;

[0084] 15 parts by weight of oxidized polyethylene wax; 17 parts by weight of oxidized microcrystalline wax;

[0085] 3 parts by weight of rice bran wax; 17 parts by weight of naphthenic oil KN4010;

[0086] 11 parts by weight of composite antirust agent, (including 7 parts by weight of barium petroleum sulfonate, 2 parts by weight of lanolin calcium soap, and 2 parts by weight of zinc naphthenate);

[0087] 5 parts by weight of thickener (including 4 parts by weight of ethylene propylene rubber and 1 part by weight of ethyl cellulose);

[0088] 0.5 parts by weight of dispersant (including 0.5 parts by weight of polyisobutylene polysuccinimide);

[0089] 1.5 parts by weight of anti-high temperat...

Embodiment 3 Embodiment 7

[0097] A kind of anti-corrosion sealing wax for bridge cables and anchor heads is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated in parts by weight:

[0098] 15-40 parts by weight of microcrystalline wax, 8-30 parts by weight of oxidized polyethylene wax;

[0099] 10-30 parts by weight of oxidized microcrystalline wax, 3-8 parts by weight of rice bran wax;

[0100] 10-30 parts by weight of naphthenic oil, 8-20 parts by weight of composite antirust agent;

[0101] 3-15 parts by weight of thickener, 0.5-1 part by weight of dispersant;

[0102] 0.5-3 parts by weight of anti-high temperature oxidant, and 0.5-1 part by weight of inorganic filler.

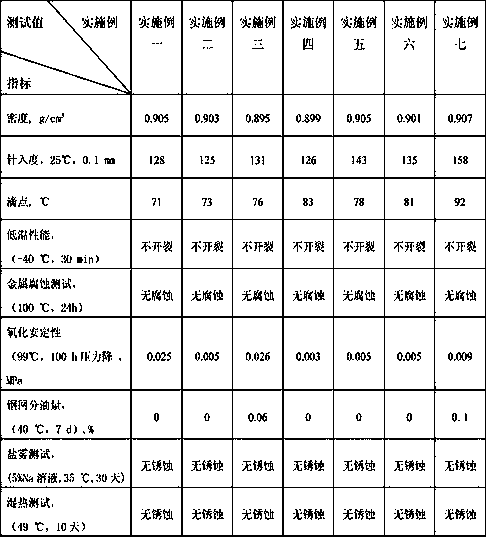

[0103] In each embodiment, for the specific content of each component, please refer to the list of the content of each component (calculated in parts by weight) of the anti-corrosion sealing wax for bridge cables and anchor heads in the attached table 1.

[0104]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com