Amino baking varnish for galvanized pipe and preparation method of amino baking varnish

A technology of amino baking varnish and galvanized pipe, which is applied in the field of amino baking varnish and its preparation, can solve the problems of galvanized pipe oxidation and other problems, and achieve the effects of enhancing adhesion, long-term anti-corrosion performance, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

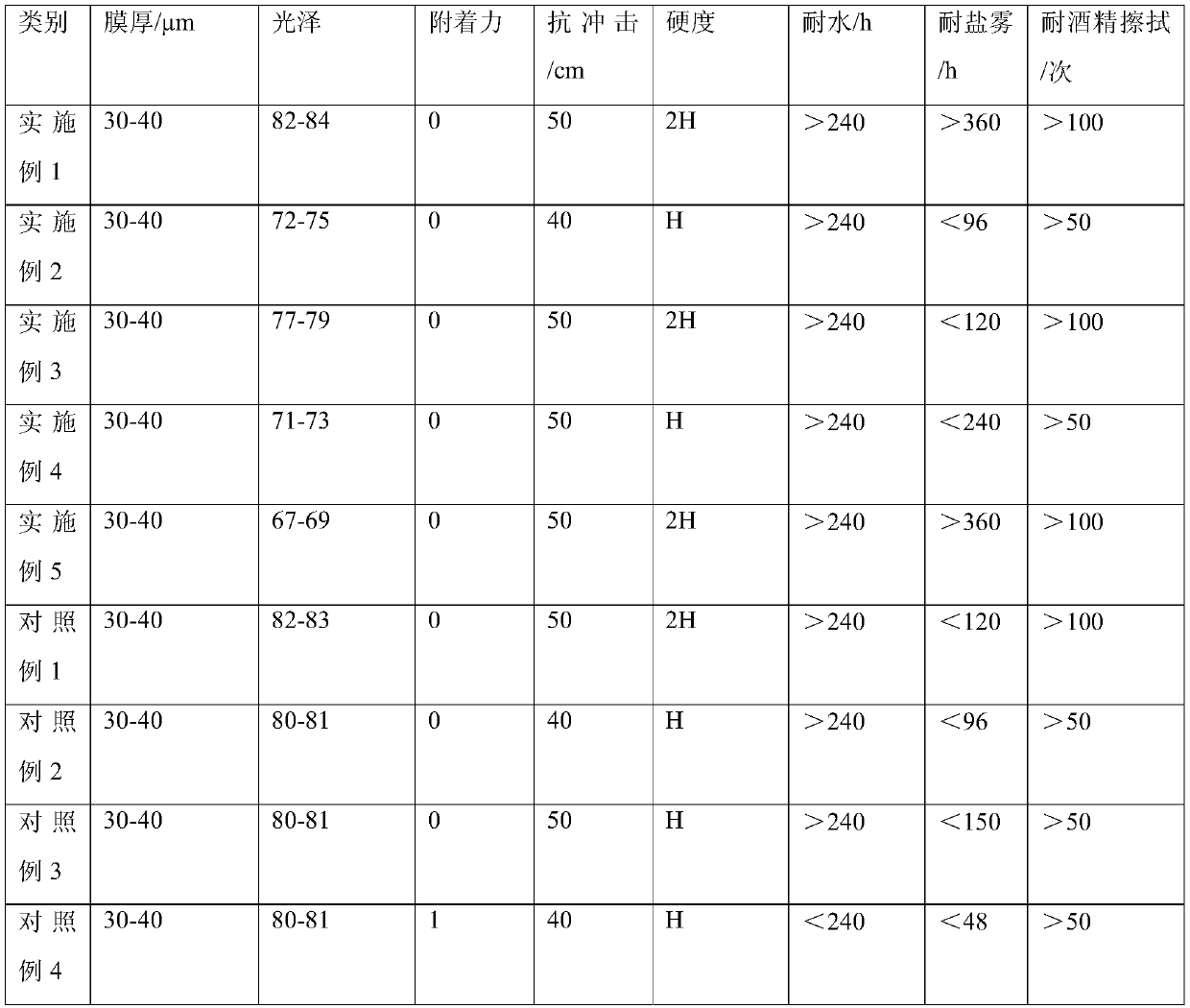

Examples

Embodiment 1

[0042] What the invention provides is the preparation method of the amino baking varnish that is used for galvanized pipe, and the step comprises:

[0043] 1) In parts by weight, add 20 parts of deionized water, 1 part of silicone defoamer, 0.1 part of organic bentonite, and 0.8 parts of dispersant in the grinding tank in sequence, and disperse for 15 minutes at a speed of 800 r / min. Form a mixture and set aside;

[0044] 2) In terms of parts by weight, first adjust the rotation speed of the grinding tank to 600r / min, while stirring the mixed solution, add 1 part of coloring pigment and 2 parts of anti-rust material in sequence, and mix evenly to prepare slurry I for later use

[0045] 3) Take 80 parts by weight of slurry I and 70 parts of zirconium beads, add zirconium beads into slurry I, adjust the rotation speed to 3000r / min, grind at a temperature lower than 50°C, and grind to fineness 20 μm, form slurry II, set aside;

[0046] 4) Preparation of finished products

[00...

Embodiment 2

[0050] What the invention provides is the preparation method of the amino baking varnish that is used for galvanized pipe, and the step comprises:

[0051] 1) In parts by weight, add 25 parts of deionized water, 1.2 parts of organic bentonite, 2 parts of organic silicon defoamer, and 1 part of dispersant in the grinding tank in sequence, and disperse for 15 minutes at a speed of 800 r / min. Form a mixture and set aside;

[0052] 2) In terms of parts by weight, first adjust the rotation speed of the grinding tank to 600r / min, while stirring the mixed solution, add 1 part of coloring pigment and 4 parts of anti-rust material in turn, mix well, and prepare slurry I for later use

[0053] 3) Take 80 parts by weight of slurry I and 70 parts of zirconium beads, add zirconium beads into slurry I, adjust the rotation speed to 3000r / min, grind at a temperature lower than 50°C, and grind to fineness 15 μm, form slurry II, set aside;

[0054] 4) Preparation of finished products

[0055...

Embodiment 3

[0058] What the invention provides is the preparation method of the amino baking varnish that is used for galvanized pipe, and the step comprises:

[0059] 1) In parts by weight, add 30 parts of deionized water, 3.5 parts of silicone defoamer, 1.4 parts of organic bentonite, and 1.1 parts of dispersant in the grinding tank in sequence, and disperse for 15 minutes at a speed of 800 r / min. Form a mixture and set aside;

[0060] 2) In terms of parts by weight, first adjust the rotation speed of the grinding tank to 700r / min, while stirring the mixed solution, add 2 parts of coloring pigment and 5 parts of anti-rust material in sequence, and mix evenly to prepare slurry I for later use

[0061] 3) Take 80 parts by weight of slurry I and 70 parts of zirconium beads, add zirconium beads into slurry I, adjust the rotation speed to 3000r / min, grind at a temperature lower than 50°C, and grind to fineness If it is less than 20 μm, form slurry II and set aside;

[0062] 4) Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com