Anticorrosive and antirust nanometer fiber paint for containers, method for preparing and spraying paint

A nanofiber and anti-rust coating technology, applied in anti-corrosion coatings, asphalt coatings, polyamide coatings, etc., can solve the problems of lack of scientificity and systematization, backwardness of anti-corrosion coating, large gap, etc., to achieve excellent mechanical properties, prolong Effect of service life and reduction of corrosion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

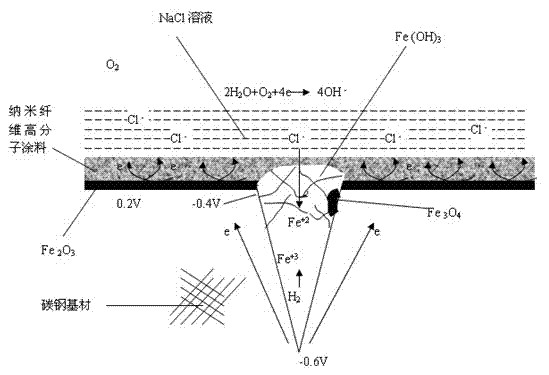

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A kind of nanofiber anticorrosion, antirust coating for container, this coating is made up of component A and component B, and described component A is by weight ratio by resin solution: talcum powder: silicon carbide: lithopone: Fe 2 0 3 -PANI nanofiber=40-60 parts: 6-8 parts: 13-22 parts: 6-10 parts: 15-20 parts; the component B is composed of 650 polyamide : mixed solvent=75 parts ~ 85 parts: 15 parts ~ 25 parts composition; Wherein, described resin solution is made up of solvent and resin, and described solvent is by weight, and solvent is by xylene: cyclohexanone: butanol=15: 3:2; the resin refers to one of E-12 epoxy resin, fluorocarbon resin, acrylic resin, polyurethane resin, chlorosulfonated polyethylene resin, silicone resin, epoxy bitumen, by weight Ratio Component A: Component B=100:10~15 to prepare anti-corrosion and anti-rust coatings.

Embodiment 2

[0063] Nanofiber anticorrosion and antirust coatings for containers, the coating is composed of component A and component B, characterized in that said component A is composed of resin solution in parts by weight: talcum powder: silicon carbide: lithopone :Fe 2 0 3 -PANI nanofiber=45 to 55 parts: 6.5 to 7.5 parts: 15 to 20 parts: 7 to 9 parts: 16 to 19 parts; the component B is composed of 650 polyamide : mixed solvent=77 parts~80 parts: 20 parts~23 parts composition; Wherein, described resin solution is made up of solvent and resin, and described solvent is by weight, and solvent is by xylene: cyclohexanone: butanol=15: 3:2; the resin refers to one of E-12 epoxy resin, fluorocarbon resin, acrylic resin, polyurethane resin, chlorosulfonated polyethylene resin, silicone resin, epoxy bitumen, by weight Ratio Component A: Component B=100:11~14 to prepare anti-corrosion and anti-rust coatings.

Embodiment 3

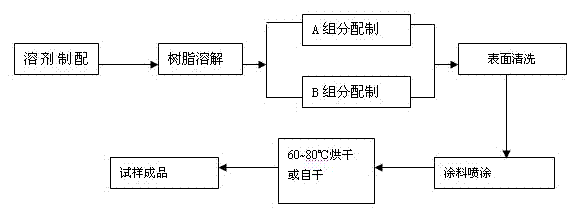

[0065] image 3 Shown, be used for the preparation method of the nanofiber anticorrosion of container, antirust coating, carry out according to the following steps:

[0066] ①, solvent preparation:

[0067] Solvent is made up of xylene, cyclohexanone, butanol, by mass ratio xylene: cyclohexanone: butanol=15:3:2;

[0068] ② Dissolution of resin

[0069] Add E-12 epoxy resin or fluorocarbon resin or acrylic resin or polyurethane resin or chlorosulfonated polyethylene resin or silicone resin or epoxy bitumen to the solvent at a constant speed and slowly, heat and stir with a strong stirrer , the heating temperature is 60°C~80°C, condense and reflux for 30min~60min, and the resin can be dissolved into a uniform transparent body;

[0070] ③, the preparation method of component A:

[0071] a. Weigh the required mass of the dissolved resin solution according to the ratio of parts by weight and pour it into the ball mill tank, and after stirring for 10 minutes at a speed of 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com