Copper-aluminum composite low-sensitive busbar and manufacturing method thereof

A copper-aluminum composite, low-inductance busbar technology, used in cable/conductor manufacturing, metal/alloy conductors, conductors, etc., can solve the problems of poor electrical conductivity of aluminum busbars, heavy weight, and high cost of pure copper busbars. Achieve lightweight design, light weight, and good environmental corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

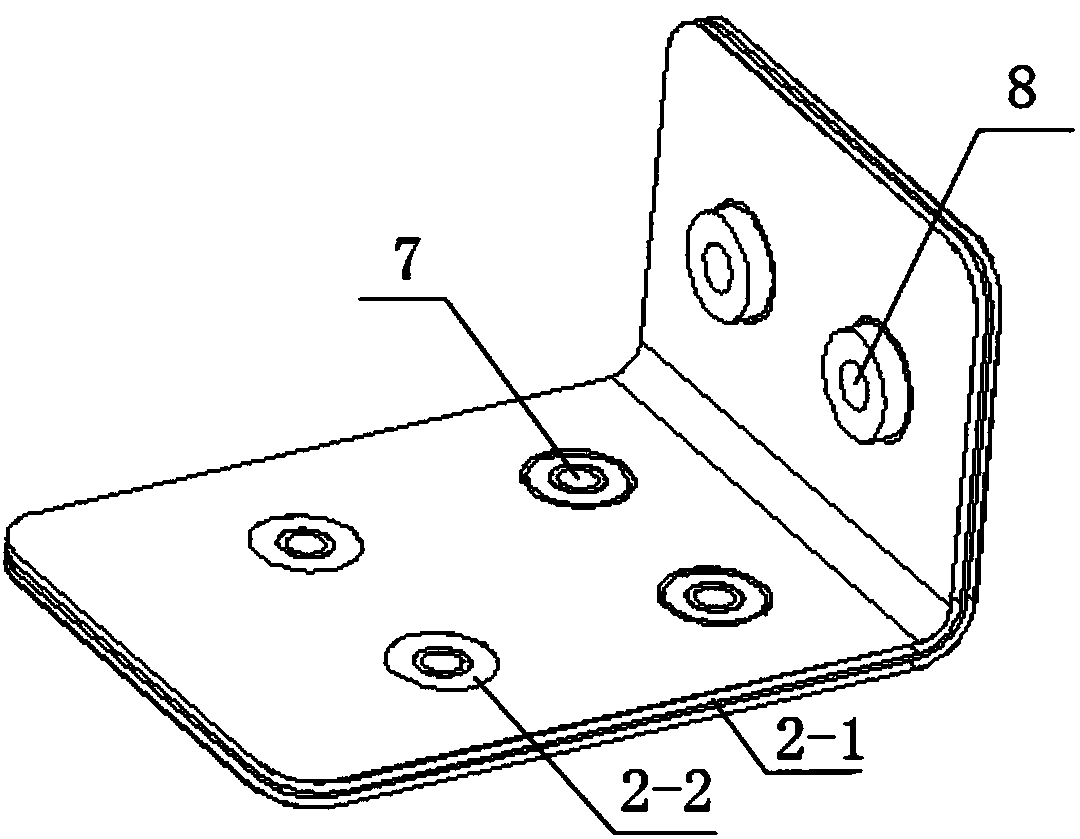

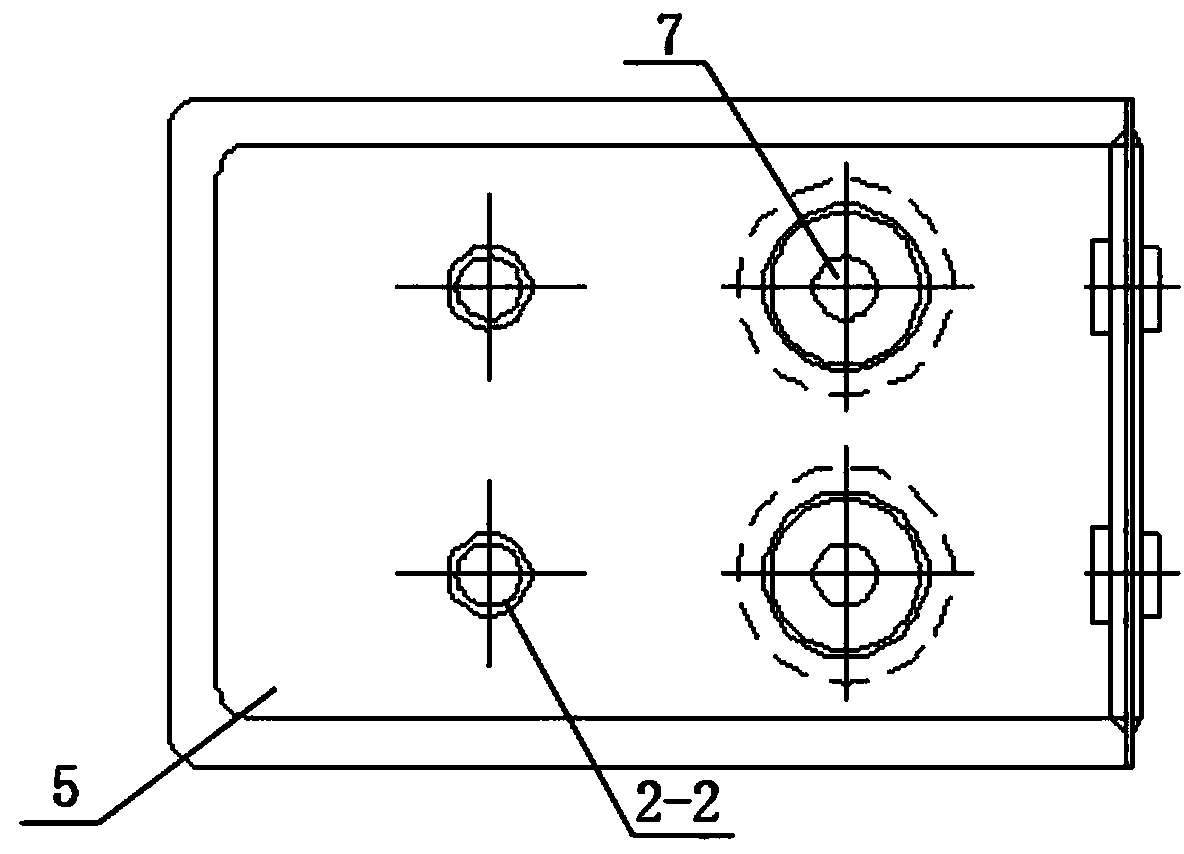

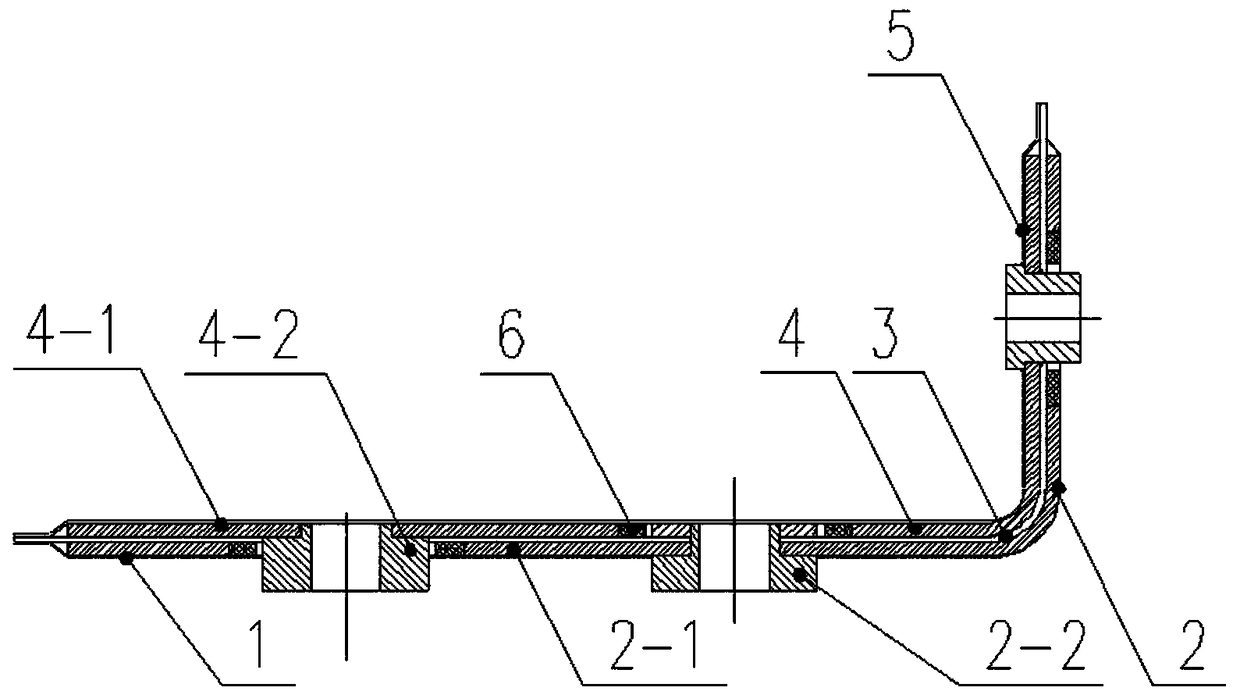

[0036] Embodiment 1 of the present invention provides a Figure 1 to Figure 4 The copper-aluminum composite low-inductance busbar shown. figure 1 It is the overall structure diagram of the copper-aluminum composite low-sensitivity busbar according to the first embodiment of the present invention. figure 2 It is a top view of the copper-aluminum composite low-sensitivity busbar according to Embodiment 1 of the present invention. image 3 It is a side view of the copper-aluminum composite low-sensitivity busbar in Embodiment 1 of the present invention. Figure 4 It is a layered view of the copper-aluminum composite low-sensitivity busbar in Embodiment 1 of the present invention.

[0037] refer to Figure 1 to Figure 4 As shown, the copper-aluminum composite low-sensitivity busbar provided by Embodiment 1 of the present invention includes a first conductor layer 2 , a second conductor layer 4 , a first insulating layer 1 , a second insulating layer 3 and a third insulating la...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a method such as Figure 4 The manufacturing method of the copper-aluminum composite low-sensitivity busbar shown. Figure 4 It is a layered view of the copper-aluminum composite low-sensitivity busbar in Embodiment 2 of the present invention.

[0049] refer to Figure 4As shown, Embodiment 2 of the present invention provides a method for manufacturing a copper-aluminum composite low-sensitivity busbar, including the following steps:

[0050] Step S1: Process the first circular through hole 7 and the second circular through hole 8 for fixing the guide post on the first copper-aluminum composite board 2-1 and the second copper-aluminum composite board 4-1 respectively.

[0051] Step S2: tinning the first copper-aluminum composite board 2-1, the second copper-aluminum composite board 4-1, the first guide post 2-2 and the second guide post 4-2 by means of electroplating.

[0052] Step S3: Attach the first insulating layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com