Salt mist-resistant moisture-resistant catalyst for removing carbon monoxide at low temperature

A carbon monoxide and salt spray-resistant technology, which is applied to catalysts for eliminating carbon monoxide at low temperature, salt spray-resistant and humidity-resistant fields, can solve the problems of common catalysts such as salt spray resistance, poor humidity resistance, unsatisfactory high temperature stability, and poor anti-poisoning performance. To achieve good CO elimination performance, enhanced catalytic activity and stability, strong resistance to salt spray and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

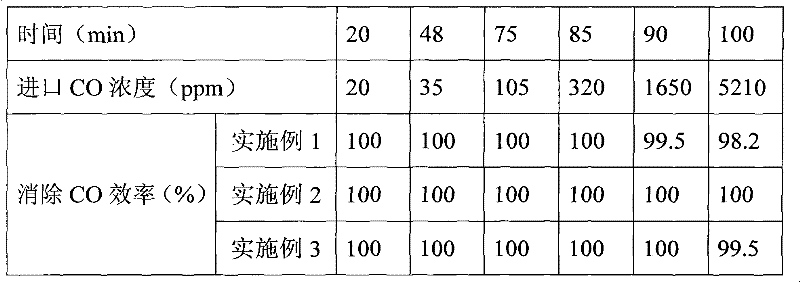

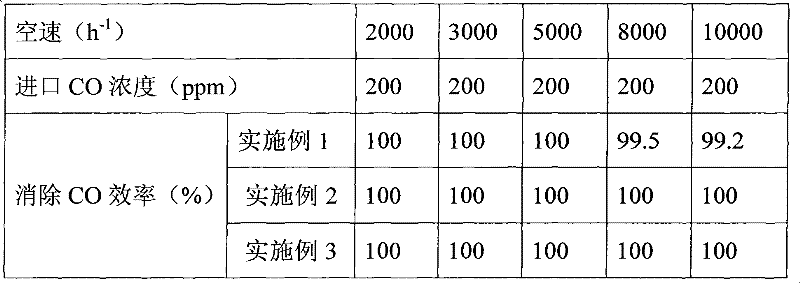

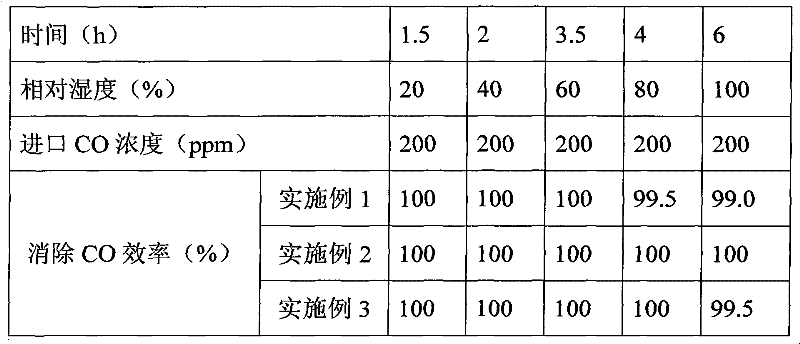

Examples

Embodiment 1

[0019] 1. Weigh 21.71gCe(NO 3 ) 3 ·6H 2 O and 21.45g Zr(NO 3 ) 4 ·5H 2 O was mixed and dissolved in 250ml deionized water, 21g of citric acid was weighed and dissolved in 220ml of deionized water, 30ml of 90% ethanol was added to aid dissolution, the citric acid solution dissolved by ethanol was dropped into the cerium-zirconium mixed solution, stirred at room temperature for 3h, and Distill under pressure to remove a certain amount of ethanol and water until the solution forms a yellow flowable gel. Foam at 120°C for 5 hours, and the obtained solid foam is calcined at 600°C for 5 hours to obtain cerium-zirconium composite oxide, which is ground and used for later use.

[0020] 2. Weigh 45.5g γ-A 2 o 3 , 73.7g of manganese carbonate, 4g of high alumina cement, adding 5g of the above-mentioned cerium-zirconium composite oxide, rolling into a ball, drying at 120°C for 3h, and roasting at 450°C for 5h to make a carrier.

[0021] 3. Weigh 0.5gPdCl respectively 2 and 0.27gH...

Embodiment 2

[0023] 1. Weigh 43.4gCe(NO 3 ) 3 ·6H 2 Dissolve O in 250ml of deionized water, weigh 21g of citric acid and dissolve in 220ml of deionized water, add 30ml of 90% ethanol to aid dissolution, drop the citric acid solution aided by ethanol into the mixed solution of cerium and zirconium, stir at room temperature for 3h, and decompress Distill to remove a certain amount of ethanol and water until the solution forms a yellow flowable gel, foam at 120°C for 5 hours, and roast the obtained solid foam at 600°C for 5 hours to obtain cerium-zirconium composite oxide, grind it, and set aside.

[0024] 2. Weigh 74g γ-A 2 o 3 , manganese carbonate 24.5g, 1g squash rubber powder, add 10g of the above-mentioned cerium-zirconium composite oxide, roll into a ball, dry at 120°C for 3h, and roast at 450°C for 5h to make a carrier.

[0025] 3. Weigh 3.34gPdCl respectively 2 and 2.66gH 2 PtCl 6 ·6H 2 Dissolve O in deionized water, dilute to 90ml, add 100g of the above-mentioned carrier, pl...

Embodiment 3

[0027] 1. Weigh 30.4gCe(NO 3 ) 3 ·6H 2 O and 12.87g Zr(NO 3 ) 4 ·5H 2 O was mixed and dissolved in 250ml deionized water, 21g of citric acid was weighed and dissolved in 220ml of deionized water, 30ml of 90% ethanol was added to aid dissolution, the citric acid solution dissolved by ethanol was dropped into the cerium-zirconium mixed solution, stirred at room temperature for 3h, and Distill under pressure to remove a certain amount of ethanol and water until the solution forms a yellow flowable gel. Foam at 120°C for 5 hours, and the obtained solid foam is calcined at 600°C for 5 hours to obtain cerium-zirconium composite oxide, which is ground and used for later use.

[0028] 2. Weigh 78g γ-A 2 o 3 , 30.8g of manganese carbonate, 2g of high alumina cement, adding 1g of the above-mentioned cerium-zirconium composite oxide, rolling into a ball, drying at 120°C for 3h, and roasting at 450°C for 5h to make a carrier.

[0029] 3. Weigh 1.67gPdCl respectively 2 and 1.33gH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com