Water-based modified pure acrylic acid anticorrosive paint

A pure acrylic, anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of polluted environment, complicated construction, anti-corrosion salt spray resistance and poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

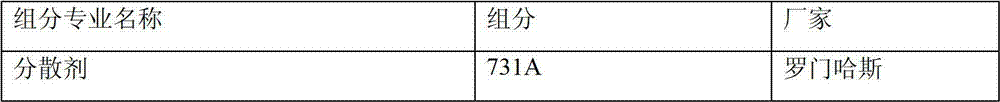

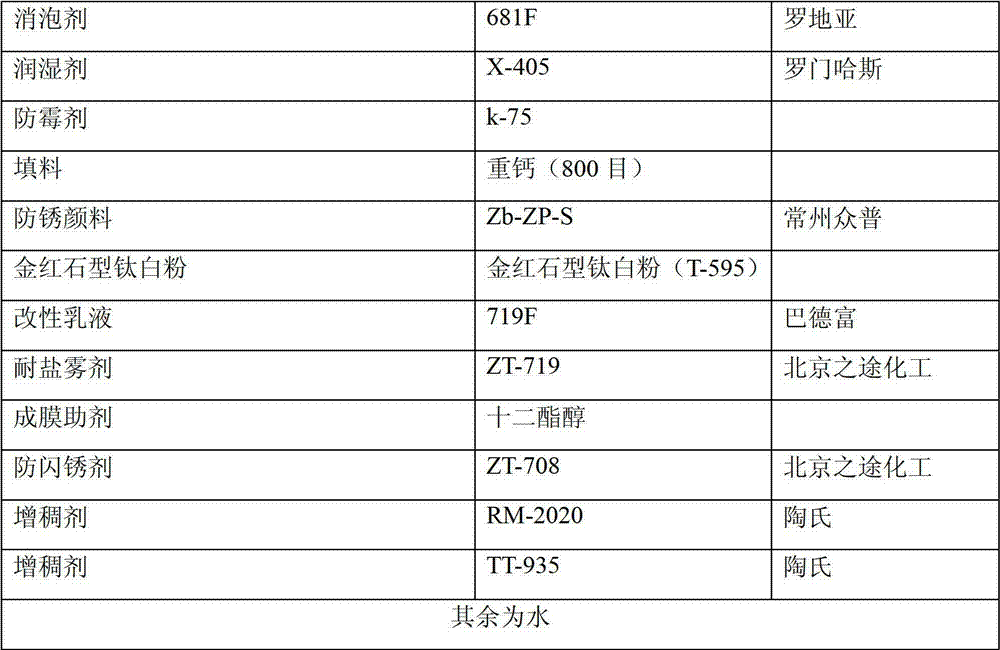

Embodiment 1

[0031] Add 18.42g of water into the batching tank according to the raw material names and proportions listed in Table 2, and add 0.59g of dispersant, 0.2g of defoamer, 0.2g of wetting agent, 0.09g of antifungal agent, and salt spray resistance under stirring. 2.5g of anti-flash rust agent, 1.0g of anti-flash rust agent, after stirring evenly, add an appropriate amount of pH regulator to adjust the pH value of the system, and make the pH value reach the range of 8.0-9.0, then add pigments, fillers and anti-corrosion pigments, stir well and put The material is pumped into a sand mill for grinding. When the fineness of the slurry is less than or equal to 50 μm, add 719F emulsion, add 3g of film-forming aid under stirring, and add thickener RM20201g, TT-9351g according to the viscosity requirements of the paint. When the product reaches the standard Finally, filter and pack with 80-100 mesh screen to obtain the finished product.

Embodiment 2-7

[0033] Adopt the same method as embodiment 1 to prepare water-based modified pure acrylic acid anticorrosion paint, the used raw material name and proportioning ratio of embodiment 2-7 are as shown in table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com