Micron-scale strong salt mist resistant and water repellent three-proof paint for circuit boards

A salt spray-resistant, micron-level technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of applying conformal paint to substances without perfluoropolyether chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

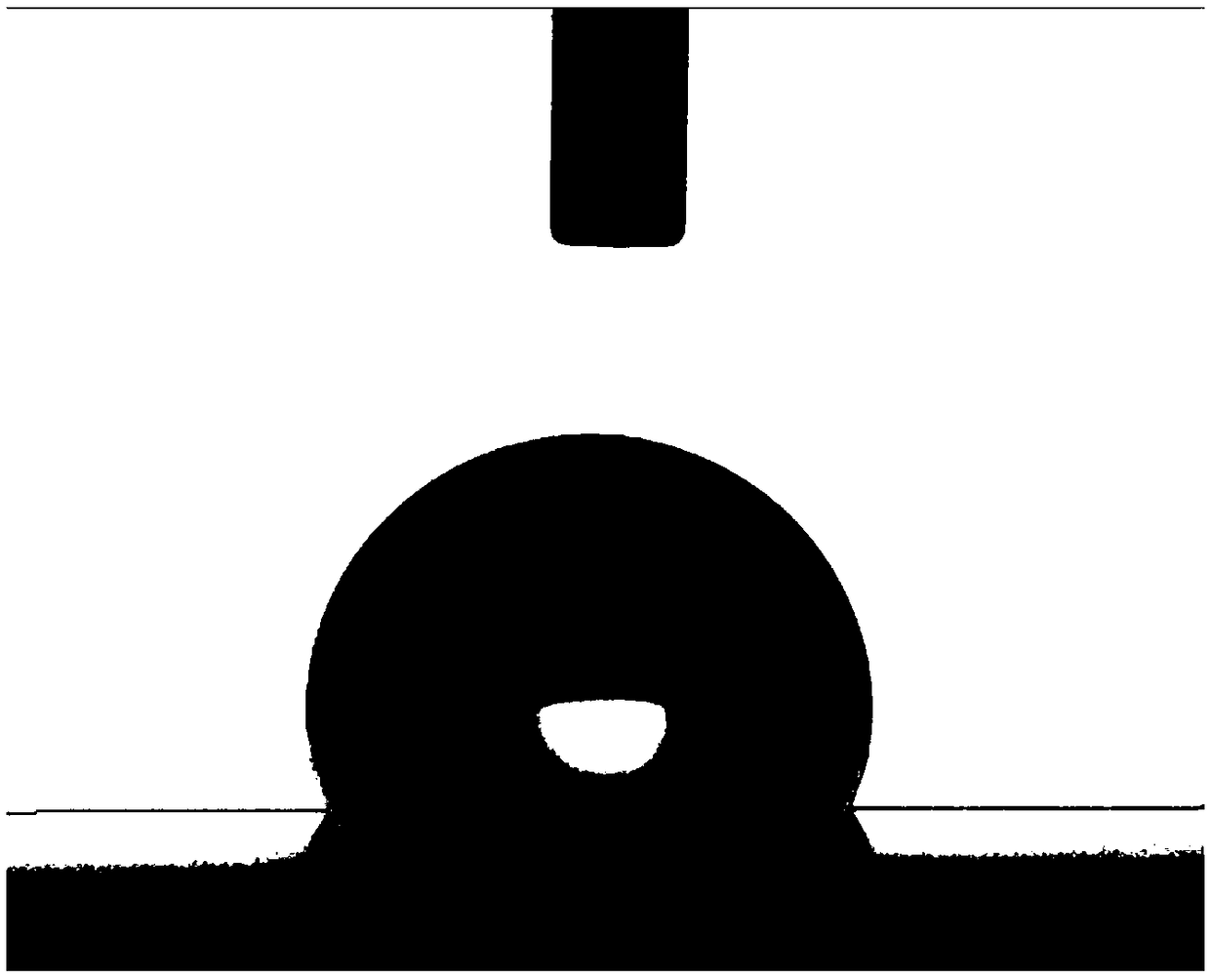

Image

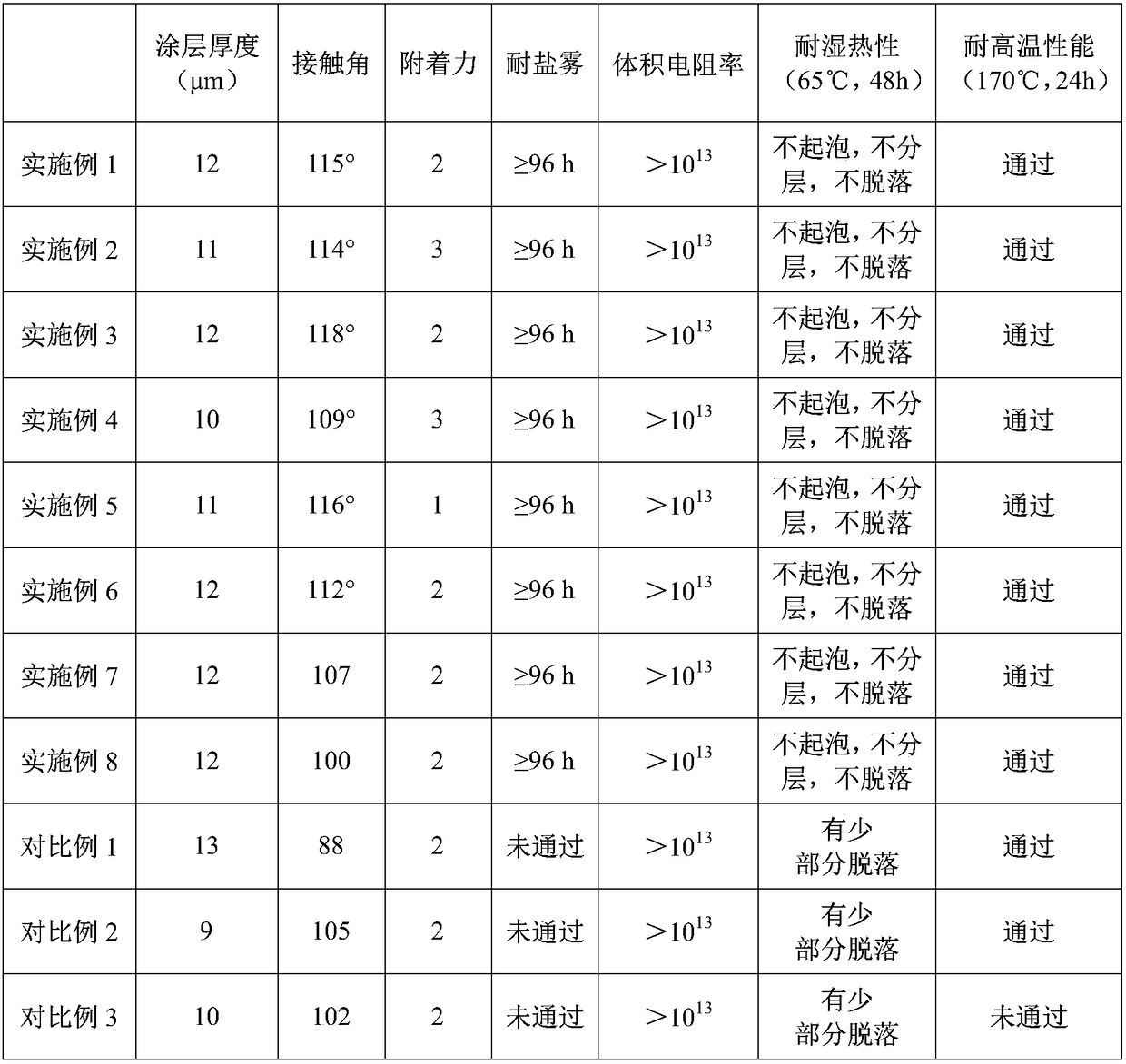

Examples

Embodiment 1

[0055] This embodiment provides a kind of anti-corrosion paint, which is prepared through the following steps:

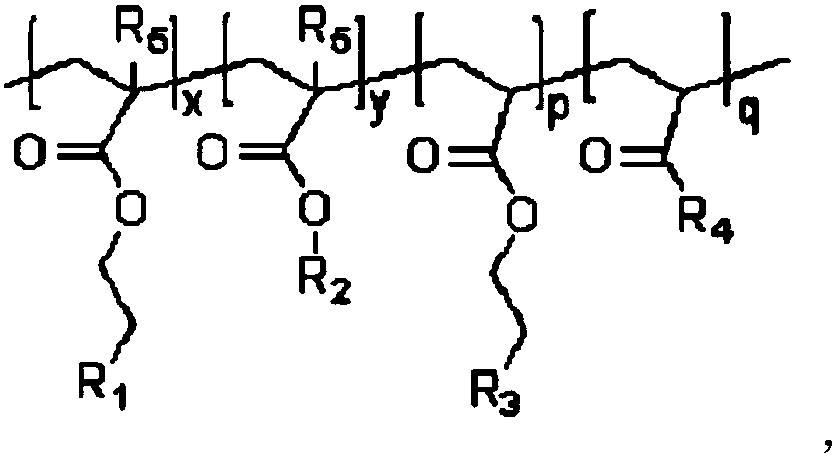

[0056] (1) Preparation of perfluoropolyether modified acrylate polymer:

[0057] In a 500mL four-neck flask equipped with a thermometer, reflux condenser, and nitrogen replacement, add 50.00g 3 CF 2 CF 2 O[CF(CF 3 ) CF 2 O] 8.7 CF(CF 3 )CH 2 CH 2 OC(O)C(CH 3 )=CH 2 , 14.00g butyl acrylate, 34.00g cyclohexyl methacrylate, 1.00g methacrylic acid, 1.00g azobisisobutyronitrile initiator and 233.00g nonafluorobutyl ether solvent. After replacing with nitrogen, the oil bath was heated to 75° C. and reacted for 10 hours. After the reaction was completed, a polymer product with a solid content of 30% was obtained.

[0058] (2) Preparation of conformal paint:

[0059] The polymer product with a solid content of 30% prepared in step (1) is diluted to 2% with nonafluorobutyl methyl ether to obtain a conformal coating.

[0060] The conformal paint prepared in this...

Embodiment 2

[0062] This embodiment provides a kind of anti-corrosion paint, which is prepared through the following steps:

[0063] (1) Preparation of perfluoropolyether modified acrylate polymer:

[0064] In a 500mL four-neck flask equipped with a thermometer, reflux condenser, and nitrogen replacement, add 50.00g 3 CF 2 CF 2 O[CF(CF 3 ) CF 2 O] 9.2 CF(CF 3 )CH 2 CH 2 OC(O)CH=CH 2 , 14.00 g octyl acrylate, 34.00 g benzyl methacrylate, 1.00 g methacrylic acid, 1.00 g azobisisobutyronitrile initiator and 233.00 g nonafluorobutyl ether solvent. After replacing with nitrogen, the oil bath was heated to 75° C. and reacted for 10 hours. After the reaction was completed, a polymer product with a solid content of 30% was obtained.

[0065] (2) Preparation of conformal paint:

[0066] The polymer product with a solid content of 30% prepared in step (1) is diluted to 5% with nonafluorobutyl methyl ether to obtain a conformal coating.

[0067] The conformal paint prepared in this embod...

Embodiment 3

[0069] This embodiment provides a kind of anti-corrosion paint, which is prepared through the following steps:

[0070] (1) Preparation of perfluoropolyether modified acrylate polymer:

[0071] In a 500mL four-neck flask equipped with a thermometer, reflux condenser, and nitrogen replacement, add 60.00g 3 CF 2 CF 2 O[CF(CF 3 ) CF 2 O] 21.1 CF(CF 3 )CON(H)CH 2 CH 2 OC(O)C(CH 3 )=CH 2 , 4.00 g lauryl acrylate, 34.00 g isobornyl methacrylate, 1.00 g acrylic acid, 1.00 g azobisisobutyronitrile initiator and 233.00 g nonafluorobutyl ether solvent. After replacing with nitrogen, the oil bath was heated to 75° C. and reacted for 10 hours. After the reaction was completed, a product with a solid content of 30% was obtained.

[0072] (2) Preparation of conformal paint:

[0073] The polymer product with a solid content of 30% prepared in step (1) is diluted to 10% with nonafluorobutyl methyl ether to obtain a conformal coating.

[0074] The conformal paint prepared in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com