Preparation method of three-dimensional reduced graphene oxide/polyaniline composite material

A composite material and graphene technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of affecting the purity of composite materials, not seeing three-dimensional reduced graphene oxide/polyaniline composite materials, and difficult advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

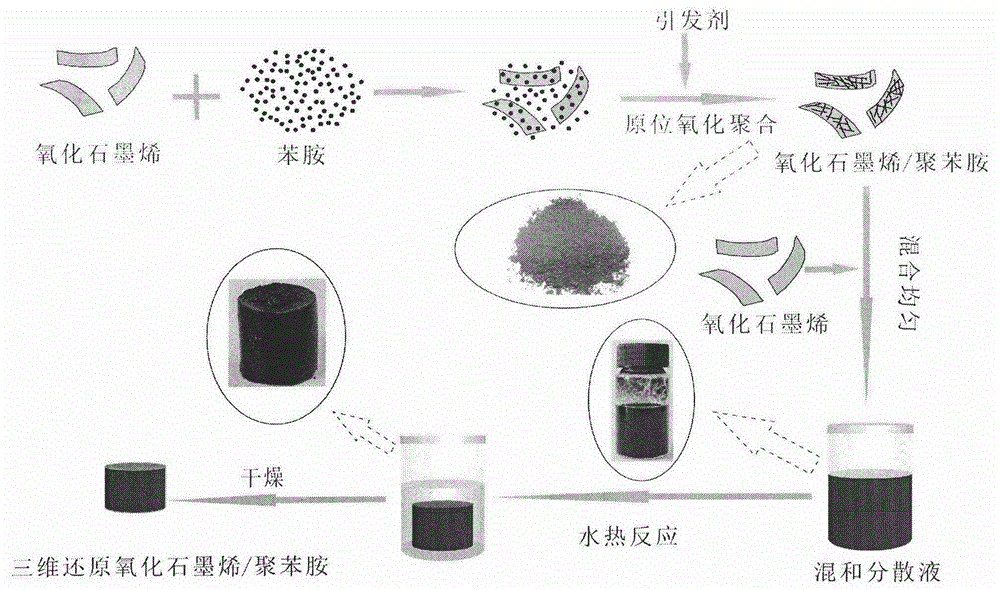

[0023] A kind of preparation method of three-dimensional reduced graphene oxide / polyaniline composite material, its preparation process is as follows figure 1 As shown, it mainly includes the following steps:

[0024] 1) Put the graphene oxide raw material and deionized water in the reactor and stir evenly to obtain a concentration of 0.5-10g L -1 Graphene oxide dispersion;

[0025] 2) Add aniline to the graphene oxide dispersion in step 1) according to the mass ratio of graphene oxide and aniline at 1:1 to 1:100, and add medium acid, stir for 30 to 60 minutes under ice bath conditions, and then Add an initiator, stir and react for 5 to 24 hours, filter the reaction product, wash and dry the filter residue to obtain a graphene oxide / polyaniline composite material, such as figure 2 As shown, the graphene oxide / polyaniline composite is in powder form;

[0026] 3) the graphene oxide / polyaniline composite material of step 2) and the graphene oxide dispersion liquid of step 1) ...

example 1

[0034] 1) Choose graphene oxide with a carbon content of 65% and a sheet diameter of 0.5 μm as a raw material, and mix graphene oxide and deionized water by mass (Kg) / volume (m 3 ) with a ratio of 1:1, add it into a reactor with a stirring device, stir and disperse evenly, and make a concentration of 1g L -1 Graphene oxide dispersion;

[0035] 2) Place the graphene oxide dispersion and aniline in step 1) in a reactor at a mass ratio of graphene oxide to aniline of 1:20, and add sulfuric acid as a medium acid, stir for 30 min under ice-bath conditions, press The molar ratio of ammonium persulfate to aniline was 1:0.2. Ammonium persulfate was added as an initiator, stirred and reacted for 7 hours, the reaction product was filtered by gravity, and the filter residue was washed and dried to obtain a graphene oxide / polyaniline composite material. Among them, after adding sulfuric acid, the concentration of sulfuric acid in the reactor is 1mol L -1 ;

[0036] 3) the graphene oxid...

example 2

[0038] 1) Choose graphene oxide with a carbon content of 90% and a sheet diameter of 20 μm as a raw material, and mix graphene oxide and deionized water by mass (Kg) / volume (m 3 ) with a ratio of 5:1, add it into a reactor with a stirring device, stir and disperse evenly, and prepare a concentration of 5g L -1 Graphene oxide dispersion;

[0039] 2) The graphene oxide dispersion and aniline in step 1) are placed in a reactor at a mass ratio of graphene oxide to aniline of 1:1, and hydrochloric acid is added as a medium acid. After stirring for 35 minutes under ice bath conditions, press The molar ratio of potassium dichromate to aniline is 1:2. Potassium dichromate is added as an initiator, stirred and reacted for 5 hours, the reaction product is filtered by pressure, and the filter residue is washed and dried to obtain a graphene oxide / polyaniline composite material. Wherein, after adding hydrochloric acid, the concentration of hydrochloric acid in the reactor is 1mol L -1 ;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com