Molybdenum disulfide nanosheet/nitrogen-doped carbon fiber hybrid material and preparation method therefor

A nitrogen-doped carbon fiber and molybdenum disulfide technology, applied in the field of carbon fiber materials, can solve the problems of restricting wide application, high price, cumbersome production process, etc., and achieve the effect of reducing agglomeration, low cost and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

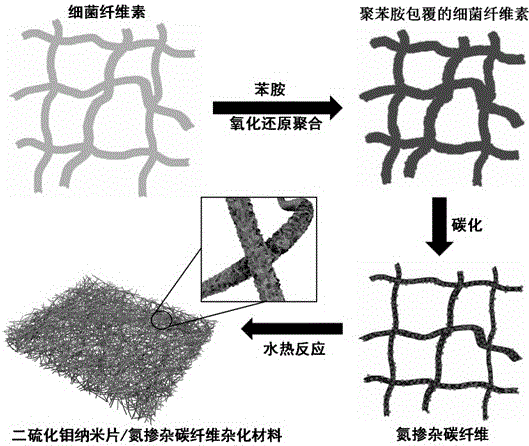

[0029] Embodiment 1, the present embodiment comprises the following steps:

[0030] (1) Preparation of nitrogen precursor-coated bacterial cellulose, the method is the same as patent CN102212210A, and the polyaniline-coated bacterial cellulose prepared by this method is denoted as BC / PANI;

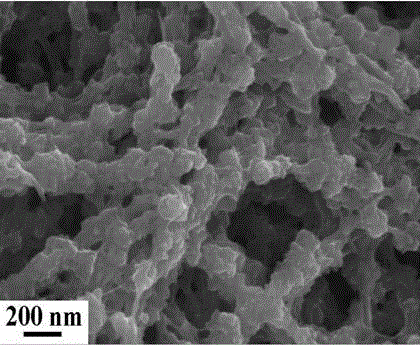

[0031] (2) Put the polyaniline-coated bacterial fibers prepared in step (1) into a tube furnace for carbonization. The conditions are: in an argon atmosphere, slowly rise from room temperature to 800°C (the heating process takes 3h ), and then keep it warm for 0.5h to obtain nitrogen-doped carbon fibers;

[0032] (3) Weigh 20mg of nitrogen-doped carbon fiber, 10mg of ammonium molybdate and 8.6mg of thiourea, put them into 25mL of solvent, and sonicate for 0.5h;

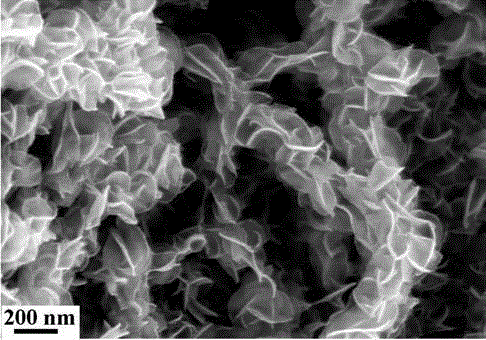

[0033] (4) Transfer the dispersion liquid containing nitrogen-doped carbon fiber, molybdenum salt and sulfur salt prepared in step (3) to a 40mL hydrothermal kettle, and conduct a hydrothermal reaction at 200°C for 12h. The blac...

Embodiment 2

[0035] Example 2, the quality of ammonium molybdate in Example 1 was changed to 90mg, the quality of thiourea was changed to 77.4mg, and the rest were the same as in Example 1, and the hybrid material finally obtained was recorded as N-CBC / MoS 2 -90. The hydrogen evolution overpotential of the hybrid material is -0.12V.

Embodiment 3

[0036] Example 3, the quality of ammonium molybdate in Example 1 is changed to 180 mg, the quality of thiourea is changed to 154.8 mg, the rest are the same as in Example 1, and the hybrid material finally obtained is recorded as N-CBC / MoS 2 -180. The hydrogen evolution overpotential of the hybrid material is -0.14V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com