Glass forming mold

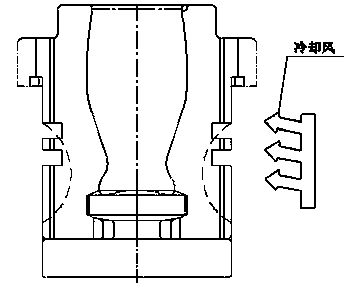

A glass forming and forming mold technology, applied in glass forming, glass blowing, glass manufacturing equipment, etc., can solve the problems of not only the body of the glass bottle, excessive cooling, inability to accurately control the cooling air flow, etc., to ensure the surface smoothness , to prevent the effect of seat bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

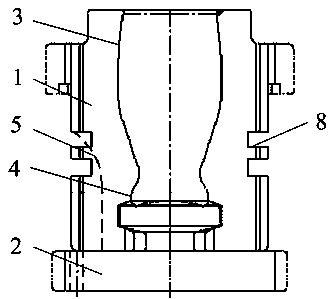

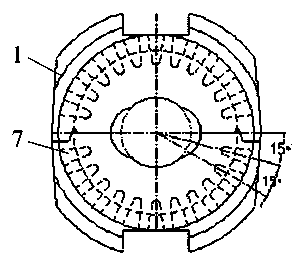

[0024] Such as figure 2 As shown, the embodiment of the present invention provides a glass forming mold, including a mold 1 and a mold bottom 2 cooperating with the bottom of the mold 1, the mold 1 is provided with a bottle body molding cavity 3, and the mold bottom 2 is provided with a bottle bottom forming cavity 4, and the forming mold is provided with a cooling channel 5 that penetrates from the bottom of the mold bottom 2 to the side wall of the forming mold 1 and extends to the middle of the forming mold 1 to communicate with the outside world .

[0025] In the above embodiment, the glass blank enters the bottle body forming cavity 3 and the bottle bottom forming cavity 4 from the upper opening of the forming mold 1, and is cooled to become a glass product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com