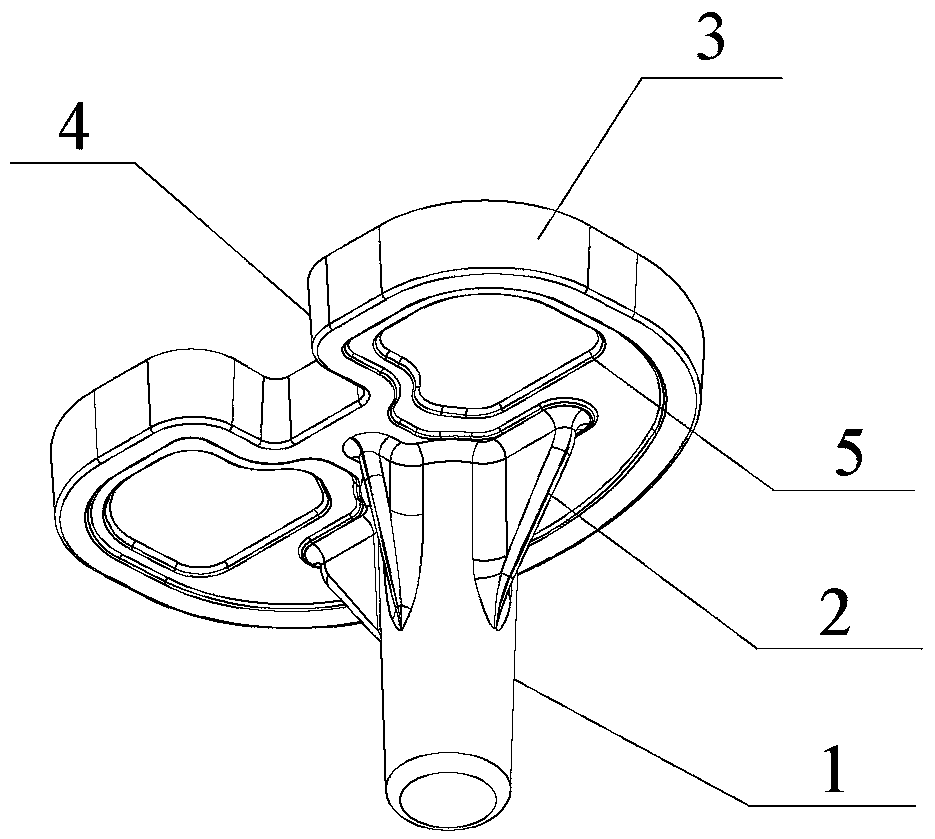

Forging method for CoCrMo tibial plateau artificial joint implant

A tibial platform and artificial joint technology, which is applied in the field of artificial joint forging processing, can solve the problems of poor dimensional accuracy, poor finish, and poor mechanical properties, and achieve the effects of avoiding friction loss, improving dimensional accuracy, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

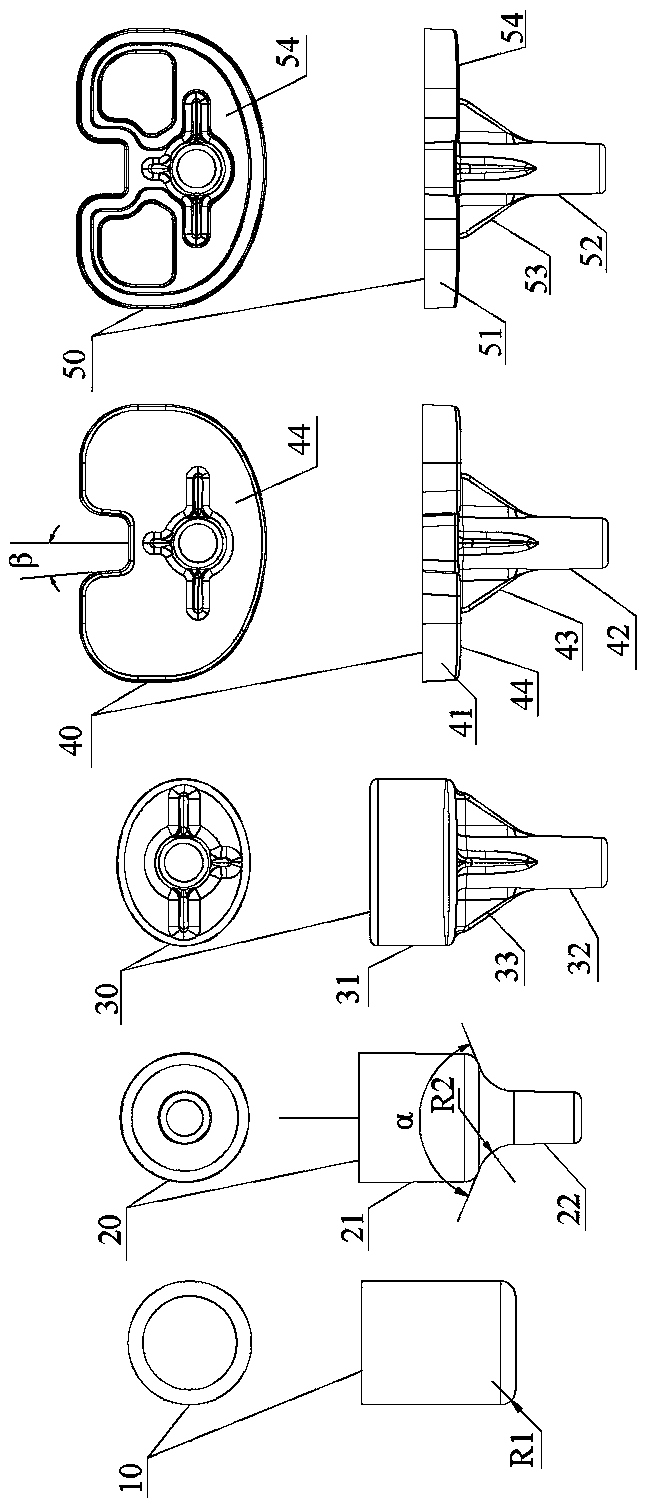

[0068] A kind of forging method of CoCrMo tibial platform artificial joint implant, it comprises the following steps:

[0069] Step 1, blanking, select φ33mm CoCrMo bar material, length 41mm, after blanking, the upper and lower end surfaces of the bar material 10 need to be flat to ensure that there are no obvious saw marks or knife marks on the end surface, and round the lower end of the bar material 10, and Its fillet radius R1 is 2mm;

[0070] Step 2, surface treatment, removing the knife marks and cutting fluid on the surface of the bar 10 through processes such as steel grit shot blasting and polishing;

[0071] Step 3, spraying, spraying anti-oxidation coating on the surface of the bar 10, the process is: heating the bar at 100°C for 90 minutes, taking it out and spraying the paint directly, the paint adopts the precision forging process with an effective protection temperature range of 1000°C~1180°C Use glass to protect the lubricant, and the thickness of the anti-oxid...

Embodiment 2

[0085] A kind of forging method of CoCrMo tibial platform artificial joint implant, it comprises the following steps:

[0086] Step 1, blanking, select φ33mm CoCrMo bar material, length 41mm, after blanking, the upper and lower end surfaces of the bar material 10 need to be flat to ensure that there are no obvious saw marks or knife marks on the end surface, and round the lower end of the bar material 10, and The fillet radius R1 is 3.5mm;

[0087] Step 2, surface treatment, removing the knife marks and cutting fluid on the surface of the bar 10 through processes such as steel grit shot blasting and polishing;

[0088] Step 3, spraying, spraying anti-oxidation coating on the surface of the bar 10, the process is: heating the bar at 150°C for 75 minutes, taking it out and spraying the paint directly, the paint adopts the precision forging process with an effective protection temperature range of 1000°C~1180°C Use glass to protect the lubricant, and the thickness of the anti-ox...

Embodiment 3

[0102] A kind of forging method of CoCrMo tibial platform artificial joint implant, it comprises the following steps:

[0103] Step 1, blanking, select φ33mm CoCrMo bar material, length 41mm, after blanking, the upper and lower end surfaces of the bar material 10 need to be flat to ensure that there are no obvious saw marks or knife marks on the end surface, and round the lower end of the bar material 10, and Its fillet radius R1 is 5mm;

[0104] Step 2, surface treatment, removing the knife marks and cutting fluid on the surface of the bar 10 through processes such as steel grit shot blasting and polishing;

[0105] Step 3, spraying, spraying anti-oxidation coating on the surface of the bar 10, the process is: heating the bar at 200°C for 60 minutes, taking it out and spraying the paint directly, the paint adopts the precision forging process with an effective protection temperature range of 1000°C~1180°C Use glass to protect the lubricant, and the thickness of the anti-oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com