Measurement method of small hardness sample and clamping fixture

A measurement method and hardness technology, applied in the direction of measuring device, testing material hardness, strength characteristics, etc., can solve the problems of inaccurate positioning, inaccurate measured data, slow speed, etc., to ensure parallelism and surface finish, improve detection Efficiency, the effect of reducing the test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Implementation one

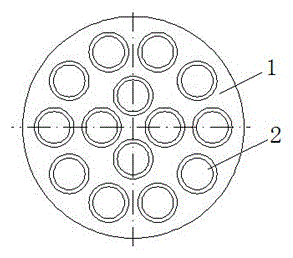

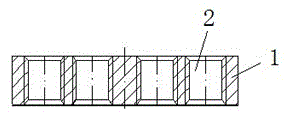

[0019] like figure 1 and figure 2 As shown in the present invention, a clamping tool for measuring small hardness samples, the clamping tool 1 is a circular structure, and 14 positioning mounting holes 2 are arranged on the clamping tool 1, and the described The positioning installation hole 2 is a threaded through hole, and a number is provided on the edge of the mouth of the positioning installation hole 2, which is convenient for distinguishing and recording.

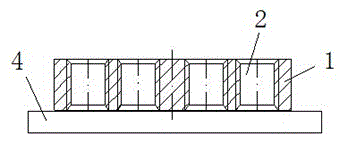

[0020] When measuring, see image 3 , first place the clamping tool 1 covered with positioning mounting holes 2 on the backing plate 4, then screw the hardness sample (bolt, screw or stud) into the positioning mounting hole 2 on the clamping tooling 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com