Titanium alloy powder, and preparation method and application thereof

A preparation method, titanium alloy technology, applied in medical science, surgery, etc., can solve the problems of cumbersome subsequent processing, high preparation cost, and biological toxicity, and achieve the effect of ensuring surface finish, excellent mechanical properties, and ensuring density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

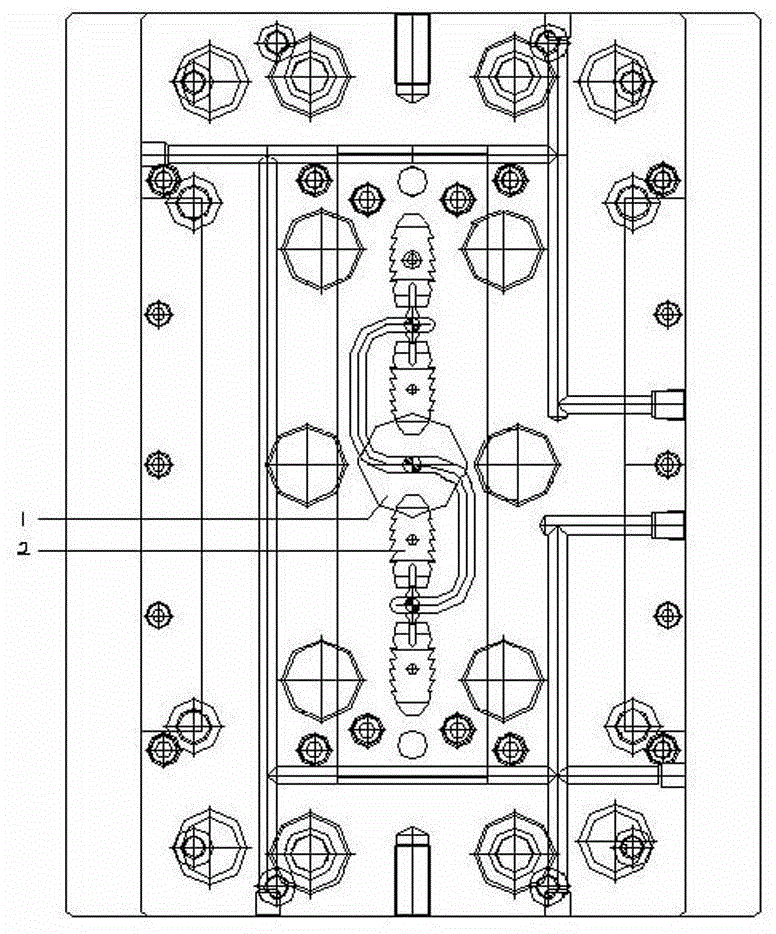

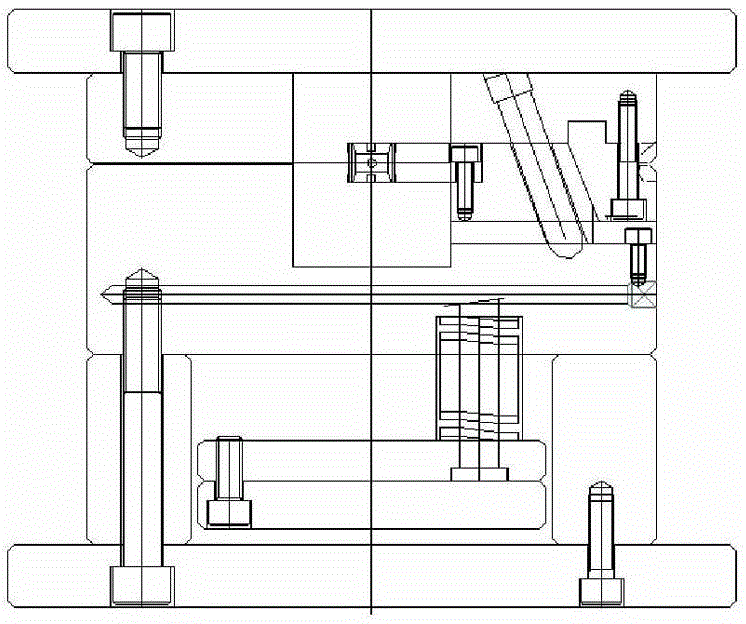

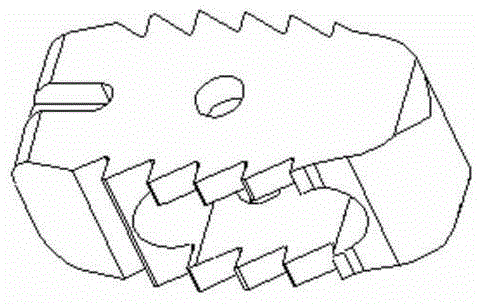

Image

Examples

Embodiment 1

[0037] A titanium alloy powder of the present invention, in terms of mass fraction, the titanium alloy powder includes aluminum powder Al 2%, molybdenum powder Mo 8%, iron powder Fe 2%, and the rest is titanium powder Ti.

[0038] In this embodiment, the particle size of each raw material powder is: aluminum powder-400 mesh, molybdenum powder-200 mesh, iron powder-300 mesh, titanium powder-400 mesh.

[0039] A method for preparing the titanium alloy powder of the above-mentioned embodiment includes weighing aluminum powder, molybdenum powder, iron powder and titanium powder with corresponding particle sizes according to the above mass fractions, and mixing the raw material powders to obtain titanium alloy powder.

[0040] An application of the above-mentioned titanium alloy powder of this embodiment is used to prepare special-shaped orthopedic implants for internal fixation of the spine, specifically using a metal powder injection molding method, including the following steps:

...

Embodiment 2

[0049] A titanium alloy powder of the present invention, in terms of mass fraction, the titanium alloy powder includes aluminum powder Al 5%, molybdenum powder Mo 4%, iron powder Fe 4%, and the rest is titanium powder Ti.

[0050] In this embodiment, the particle size of each raw material powder is: aluminum powder-400 mesh, molybdenum powder-200 mesh, iron powder-300 mesh, titanium powder-300 mesh.

[0051] A method for preparing the titanium alloy powder of the above-mentioned embodiment includes weighing aluminum powder, molybdenum powder, iron powder and titanium powder with corresponding particle sizes according to the above mass fractions, and mixing the raw material powders to obtain titanium alloy powder.

[0052] An application of the above-mentioned titanium alloy powder of this embodiment is used to prepare special-shaped orthopedic implants for internal fixation of the spine, specifically using a metal powder injection molding method, including the following steps: ...

Embodiment 3

[0060] A titanium alloy powder of the present invention, in terms of mass fraction, the titanium alloy powder includes 7% aluminum powder Al, 2% molybdenum powder Mo, 6% iron powder Fe, and the rest is titanium powder Ti.

[0061] In this embodiment, the particle size of each raw material powder is: aluminum powder-400 mesh, molybdenum powder-200 mesh, iron powder-300 mesh, titanium powder-500 mesh.

[0062] A method for preparing the titanium alloy powder of the above-mentioned embodiment includes weighing aluminum powder, molybdenum powder, iron powder and titanium powder with corresponding particle sizes according to the above mass fractions, and mixing the raw material powders to obtain titanium alloy powder.

[0063] An application of the above-mentioned titanium alloy powder of this embodiment is used to prepare special-shaped orthopedic implants for internal fixation of the spine, specifically using a metal powder injection molding method, including the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com