Adsorption dust-extraction device for textile equipment

A technology of dust removal device and textile equipment, applied in the direction of removing smoke and dust, cleaning by electrostatic method, chemical instruments and methods, etc., can solve problems such as affecting production efficiency, equipment failure, environmental pollution, etc. Good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

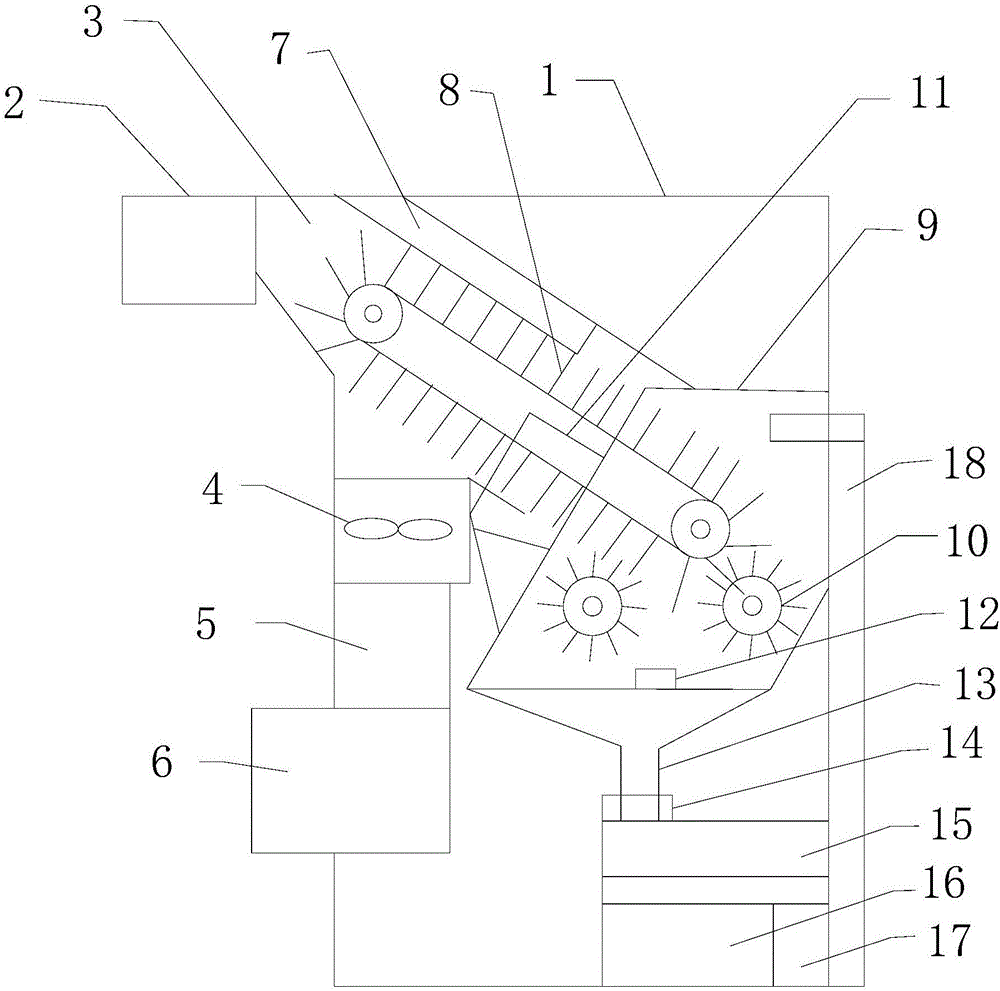

[0017] refer to figure 1 , an adsorption and dust removal device for textile equipment of the present invention, comprising a frame 1, an air suction port 2, an air inlet duct 3, a suction motor 4, an air filter box 5, an air exhaust port 6, an electrostatic dust collection plate 7, and a transmission brush belt 8 , dust removal scrub tank 9, cleaning brush roll 10, filter dry box 11, dirt detector 12, drain pipe 13, drain solenoid valve 14, filter box 15, water storage tank 16, water delivery pump 17, water delivery pipe 18, the machine The top of the frame 1 is provided with an air suction port 2, the inner side of the air suction port 2 is connected with an air inlet duct 3, the top of the air inlet duct 3 is provided with an electrostatic dust collection board 7, and a transmission brush is provided below the electrostatic dust collection board 7 Belt 8, the lower right side of the transmission brush belt 8 is provided with a dust removal scrub tank 9, a number of cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com