Hydrogen production and storage system and multi-mode circulating hydrogen production method

A hydrogen storage and mode technology, applied in the field of hydrogen production, to achieve the effect of increasing continuous working time, increasing cold start speed, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

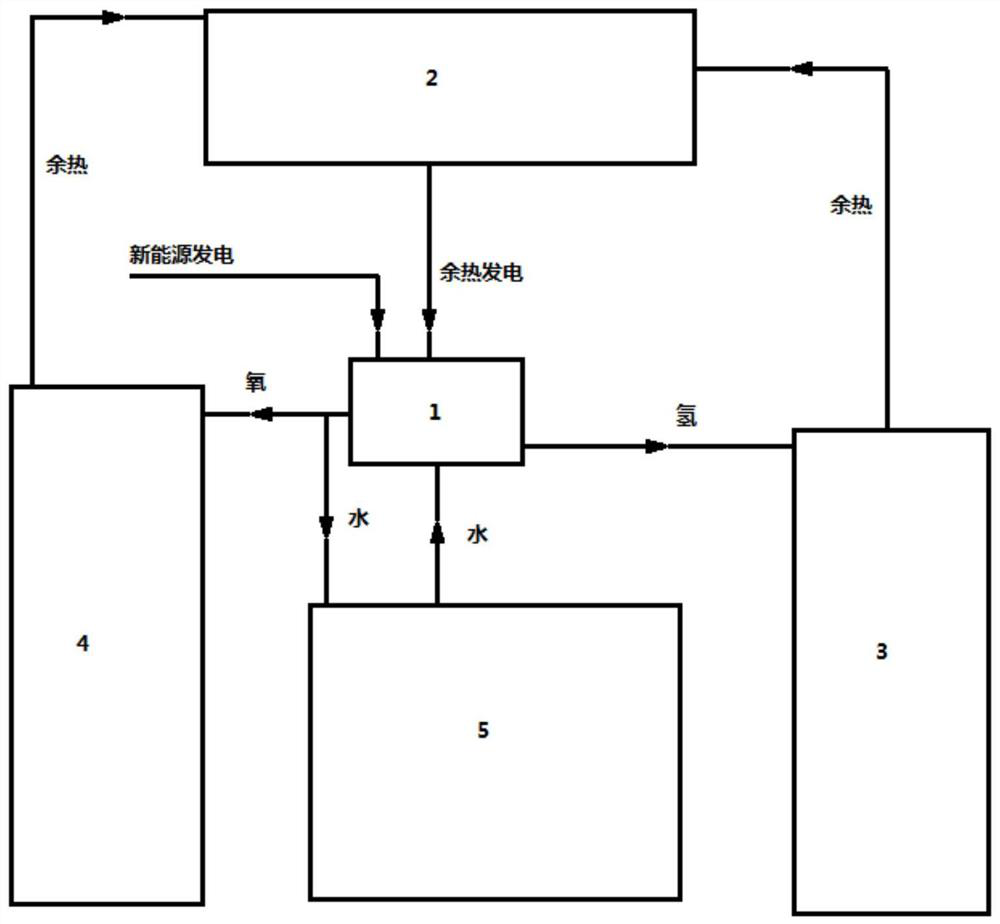

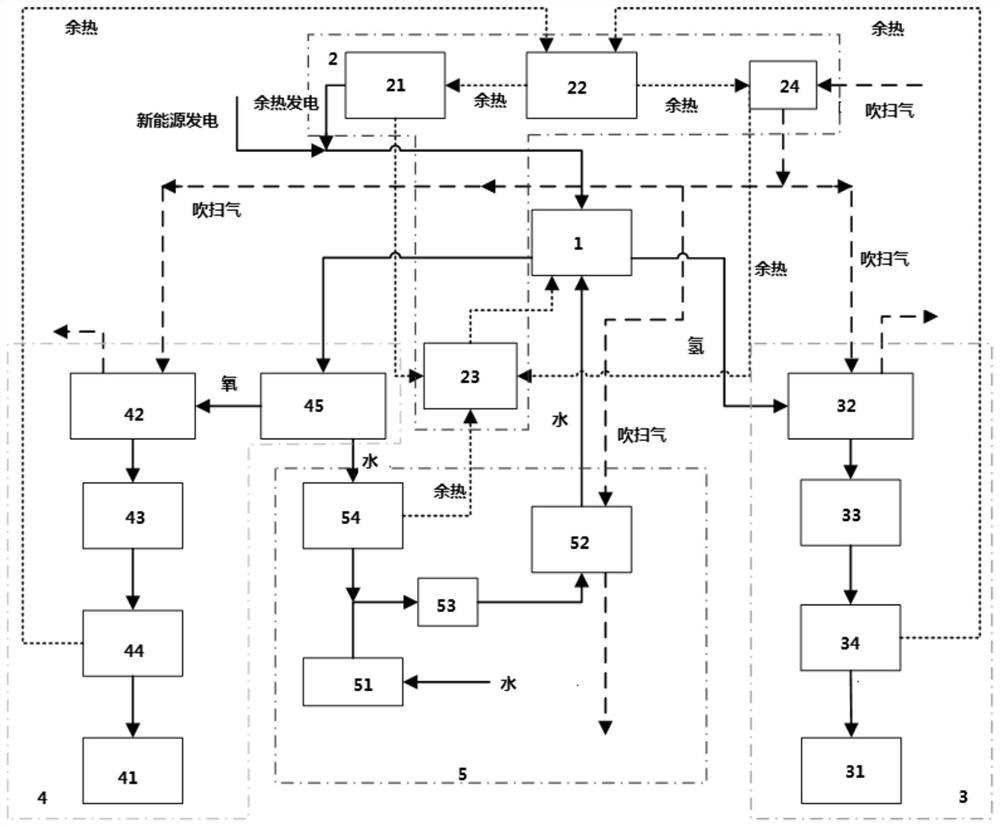

[0058] This embodiment provides a hydrogen production and storage system, the structure of which is as follows figure 1 As shown, it includes an electrolyzer 1, a thermal storage power generation device 2, a hydrogen storage device 3, an oxygen storage device 4 and a water storage device 5;

[0059] The electrolyzer 1 is used to electrolyze water to produce hydrogen;

[0060] The hydrogen storage device 3 is used to store the hydrogen produced by the electrolyzer;

[0061] The water storage device 5 is used to provide the water required by the electrolytic cell 1 and store the water taken out of the electrolytic cell 1 along with the oxygen.

[0062] The oxygen and water produced by the electrolytic cell 1 enter the oxygen storage device 2 and the water storage device respectively after being separated;

[0063] The waste heat of the hydrogen storage device 3 and oxygen storage device 4 during hydrogen storage and oxygen storage is converted into high-grade heat through the ...

Embodiment 2

[0073] This embodiment is a multi-mode cycle hydrogen production method specifically using the hydrogen production and storage system provided in Example 1, including the following modes:

[0074] Mode 1: When the renewable energy power generation is sufficient, the renewable energy power generation is rectified to drive the electrolyzer to work, and the heat storage power generation device does not generate power;

[0075] Mode 2: When the renewable energy power generation fluctuates, the regenerative power generation device will cooperate with the renewable energy power generation to drive the electrolyzer to work;

[0076] Mode 3: When there is no renewable energy power generation, the heat storage power generation device generates power to drive the electrolyzer to work;

[0077] Mode 4: When the hydrogen production system is restarted, the heat stored in the medium-temperature heat storage unit is used to enter the electrolytic cell through deionized water, so that the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com