High-efficiency electric compressor rotating speed control method based on evaporator temperature control

An evaporator temperature, electric compressor technology, applied in heating/cooling equipment, air handling equipment, component optimization, etc., can solve problems such as increased mileage anxiety, system complexity, high cost investment, etc., to prevent liquid hammer and system operation. The effect of smooth and comfortable, increased hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

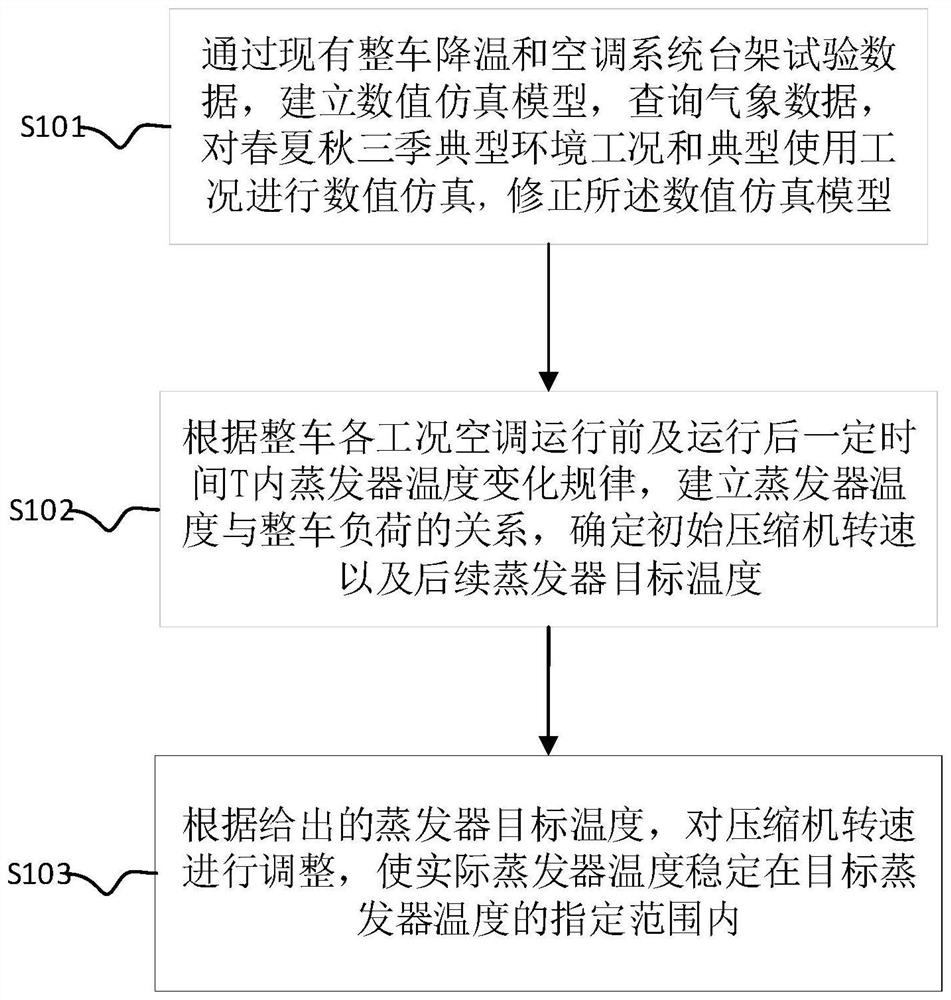

[0013] A high-efficiency electric compressor speed control method based on evaporator temperature control, comprising the following steps:

[0014] S101: Establish a numerical simulation model based on the bench test data of the existing vehicle cooling and air conditioning system; as an embodiment, the present invention takes a hydrogen fuel cell vehicle as an example.

[0015] The heat load of the car is 4kw under the design working condition, and it is matched with a 27cc electric compressor (the speed is between 1000-6000rpm). According to the test data and simulation results, the relationship between the evaporator temperature Te (°C) and the sunlight intensity I (w / ㎡) and the ambient temperature Tw after the vehicle is air-dried and stabilized can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com