Snow ice clear away car for railway

A technology for ice and snow and railways, applied in track cleaning, cleaning methods, construction, etc., can solve the problems of high fuel energy, single function, poor ice and snow removal effect, etc., and achieve good operation continuity, high degree of automation, and complete functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

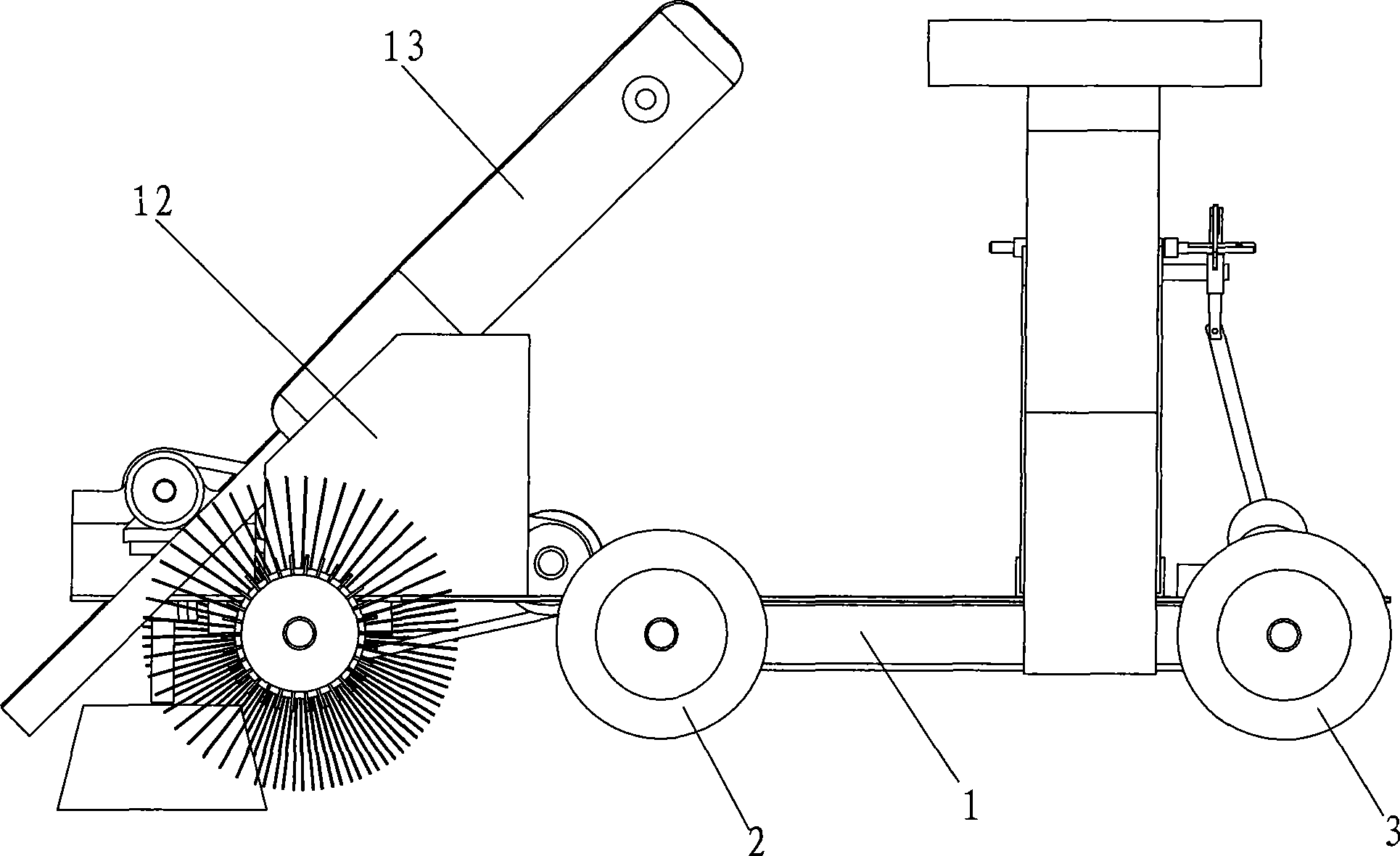

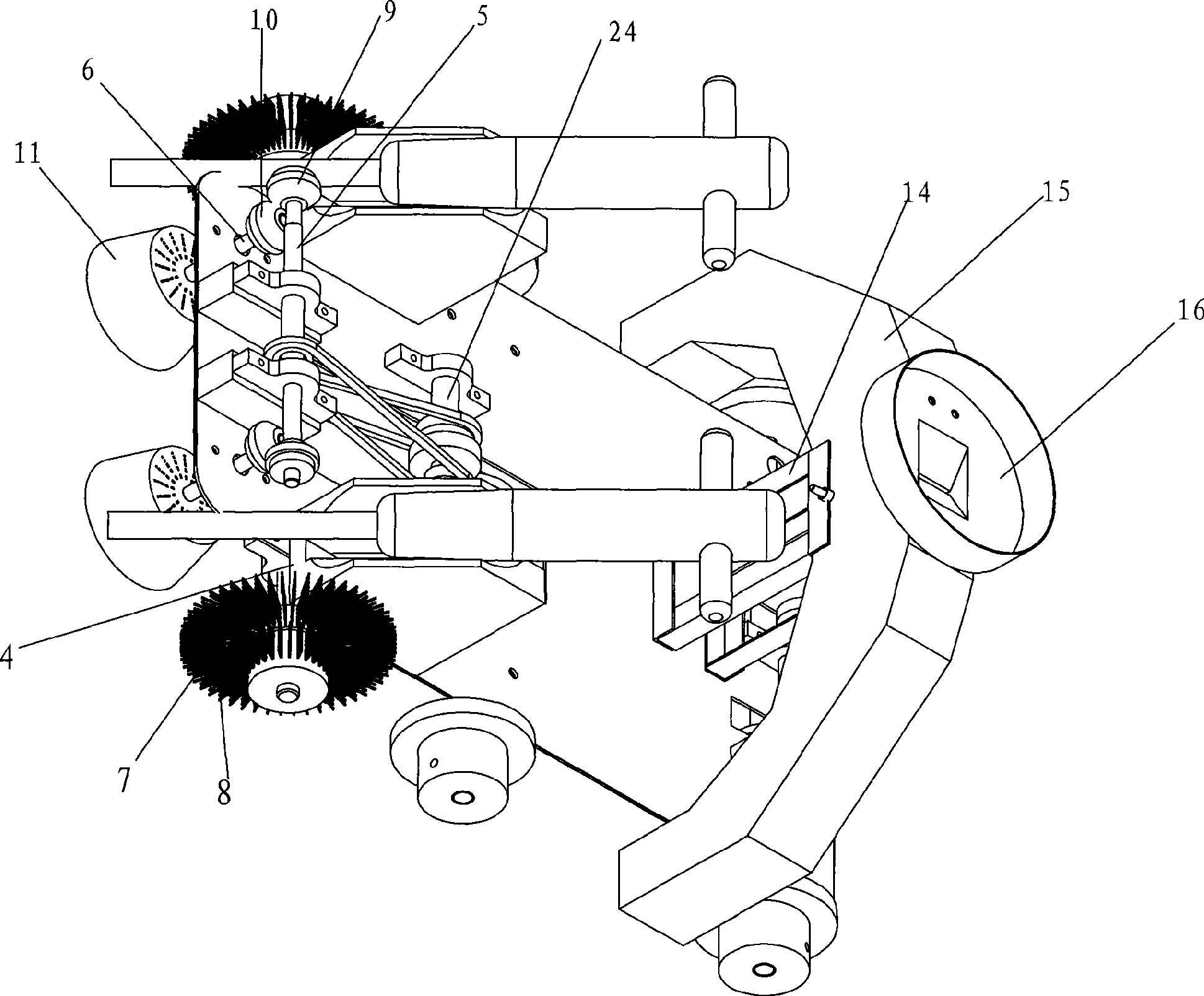

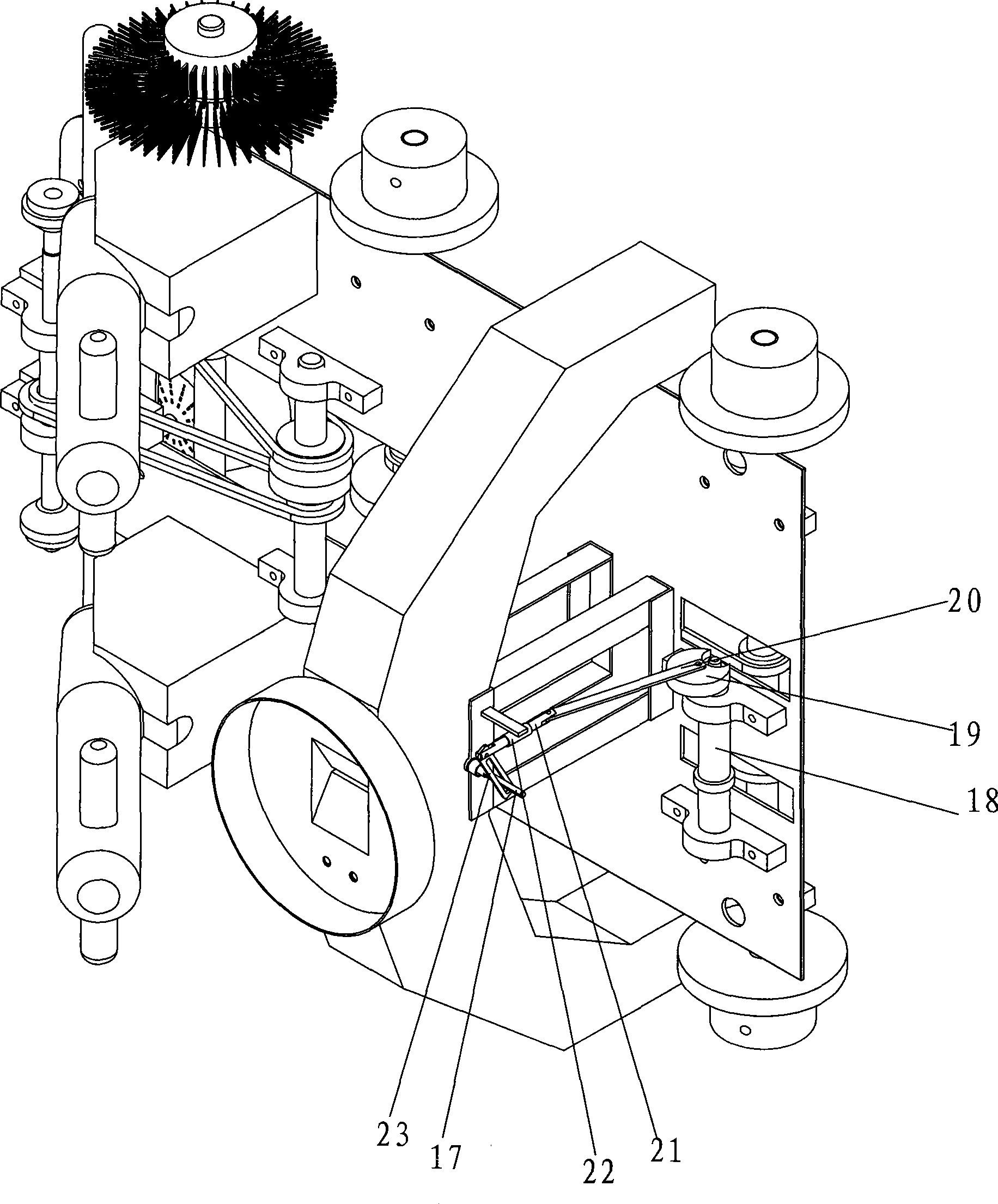

[0022] refer to Figure 1-3 A kind of railway ice and snow clearing vehicle comprises vehicle frame 1, front wheel 2, rear wheel 3, and described front wheel 2, rear wheel 3 are contained on the vehicle frame 1 by front wheel shaft, rear wheel shaft respectively, also on the described vehicle frame Equipped with ice and snow removal device, symmetrical salt spreading device and power device;

[0023] Described ice and snow clearing device comprises the first working shaft 4, the first intermediate shaft 5 and the second working shaft 6 that are contained in the front wheel shaft place ahead, and described first working shaft 4 is connected with front wheel shaft transmission, and the first working shaft 4 Both ends are equipped with a sun gear 7, and the blades 8 are evenly distributed on the sun gear 7; the first intermediate shaft 5 is connected to the front wheel shaft, and the two ends of the first intermediate shaft 5 are equipped with a driving bevel gear 9, so The uppe...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment lies in that: one end of the second intermediate shaft is vertically fixed to a connecting rod, and the other end of the connecting rod is hinged to the crank. Other structures and implementations of this embodiment are completely the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com