Device for recycling oil or solvent from solid-containing oil through spray flash evaporation drying and recycling method

A technology for flash drying and oil products, applied in the field of coal chemical industry, can solve the problem of not giving full play to the advantages of high value-added components in oil residues, and achieve the effects of not easily leaking dust and toxic gases, reducing evaporation temperature, and shortening drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

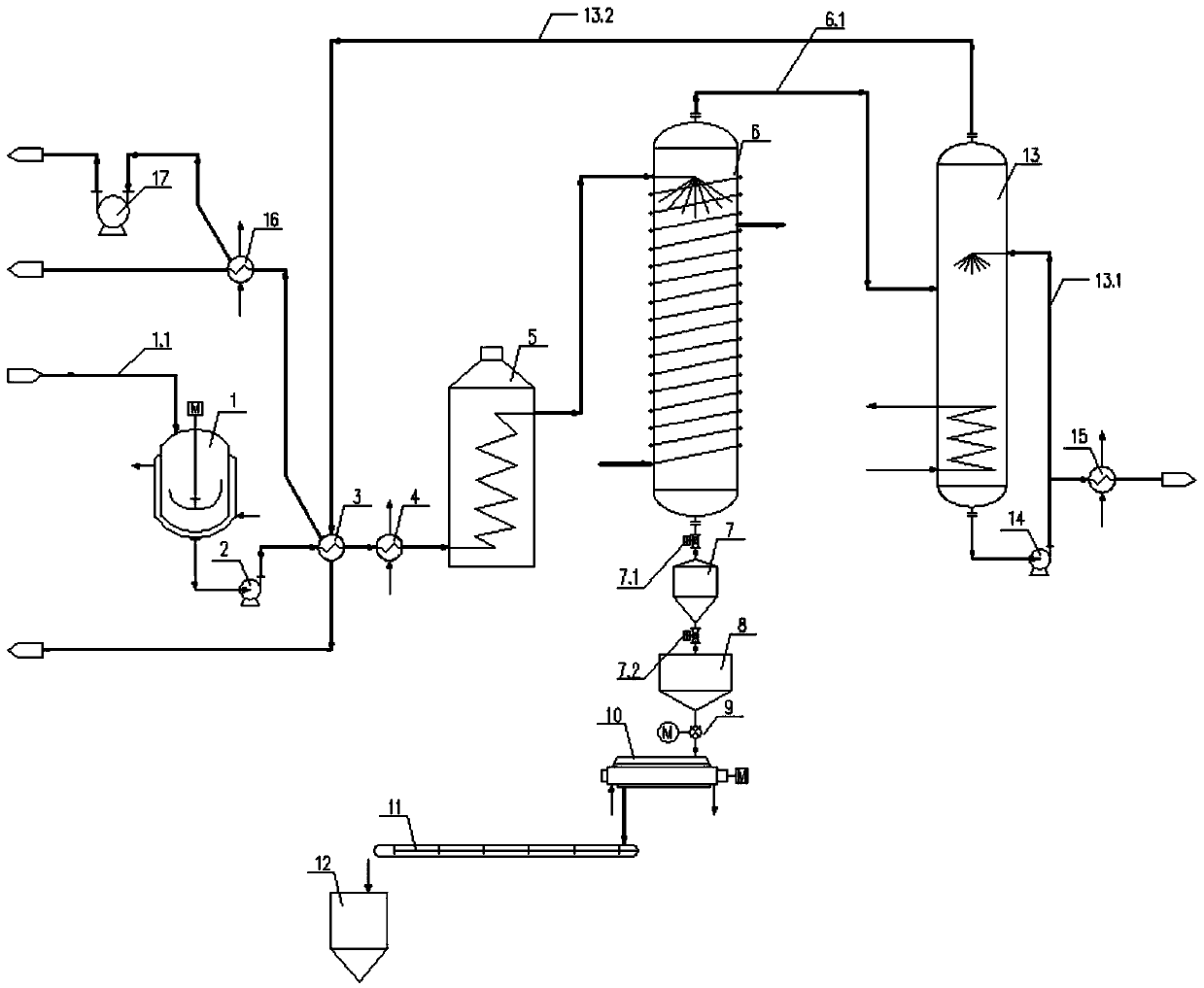

[0051] Such as figure 1 As shown, the raw material is a recovery process of the extractant in a coal-based oil residue raffinate of a coal chemical plant. The process is a spray drying operation under reduced pressure. The specific steps include:

[0052] (1) The first choice is to input the extractant in the viscous oil residue, that is, the coal-based oil residue raffinate, into the raw material buffer tank 1 through the raw material delivery pipeline 1.1 and pressurize it through the feed pump 2, and then send it to the oil residue preheater 3, After exchanging heat with the oil gas (or solvent) at the top of the spray flash drying tower 6, it is sent to the oil residue heater 4 to exchange heat with the heat transfer oil to 200-250°C, and then enters the heating furnace 5 to be heated to about 360-380°C, and then enters the In the spray flash drying tower 6, the specific feed position is close to the upper side of the spray flash drying tower; meanwhile, the spray flash dr...

Embodiment 2

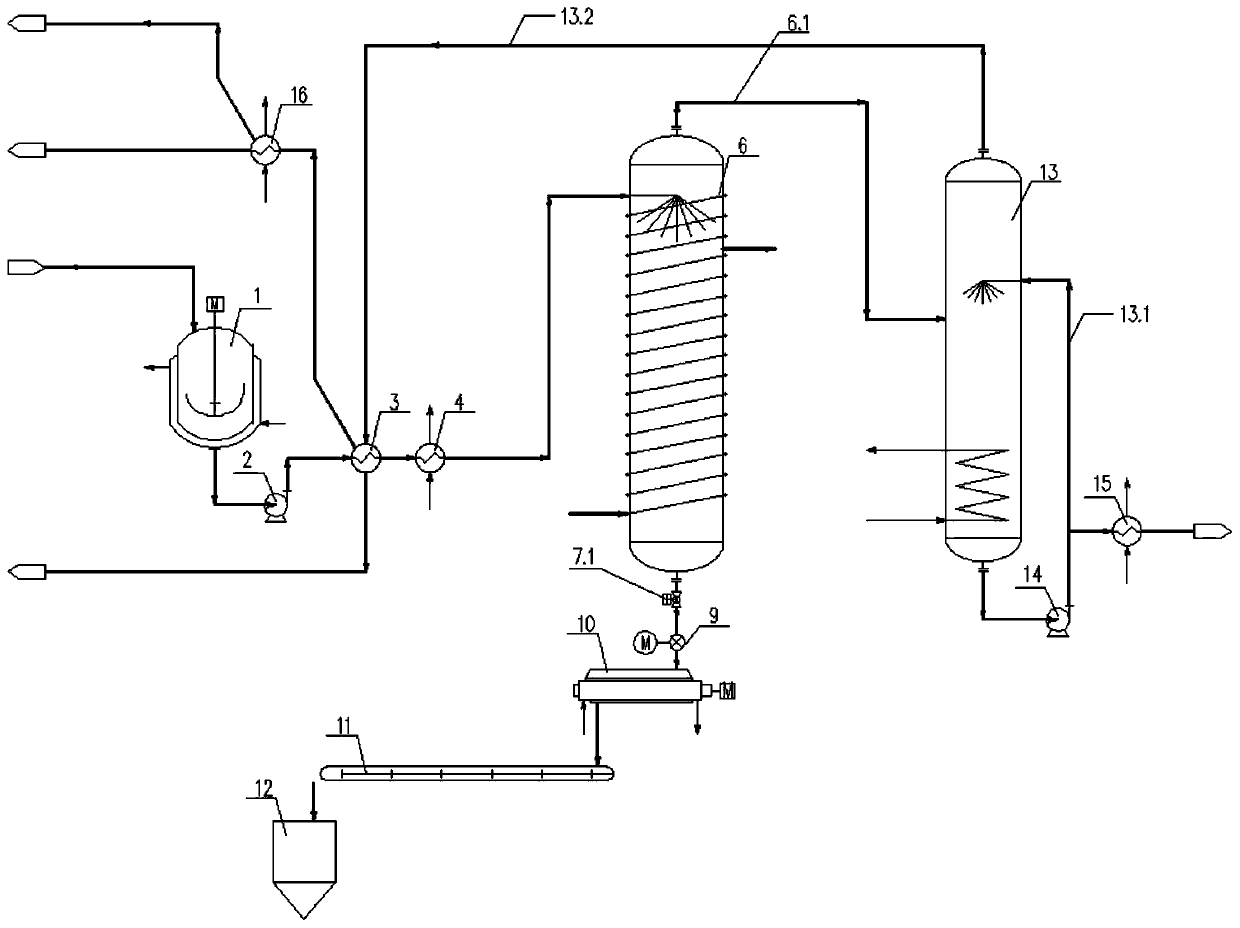

[0058] Such as figure 2 As shown, the raw material is naphtha, and the oil product therein is light oil, so it can be flashed under normal pressure. Compared with Example 1, the specific process device has no dry material lock hopper, dry material bin, heating furnace and vacuum pump. Others are with embodiment 1.

[0059] Application process method of the present invention can adopt following steps

[0060] Include the following steps:

[0061] (1) Input the naphtha into the feed buffer tank 1, and after being pressurized by the feed pump 2, send it to the preheater 3, and send it to the The heater 4 exchanges heat with the heat transfer oil to about 280°C and enters the spray flash drying tower 6; at the same time, the spray flash drying tower 6 quickly flashes the light oil under normal pressure conditions to obtain light oil and gas respectively. Phases and powdery dry granules;

[0062] (2) The powdery dry particles are fed into the dry phase cooler 10 by gravity sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com