Food garbage solid-liquid separation and sterilization integrated device

A technology for solid-liquid separation and food waste, which is applied to presses, manufacturing tools, etc., can solve problems such as low efficiency, bulky size, and poor operation continuity, so as to reduce time waste, improve production efficiency, and evenly sterilize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

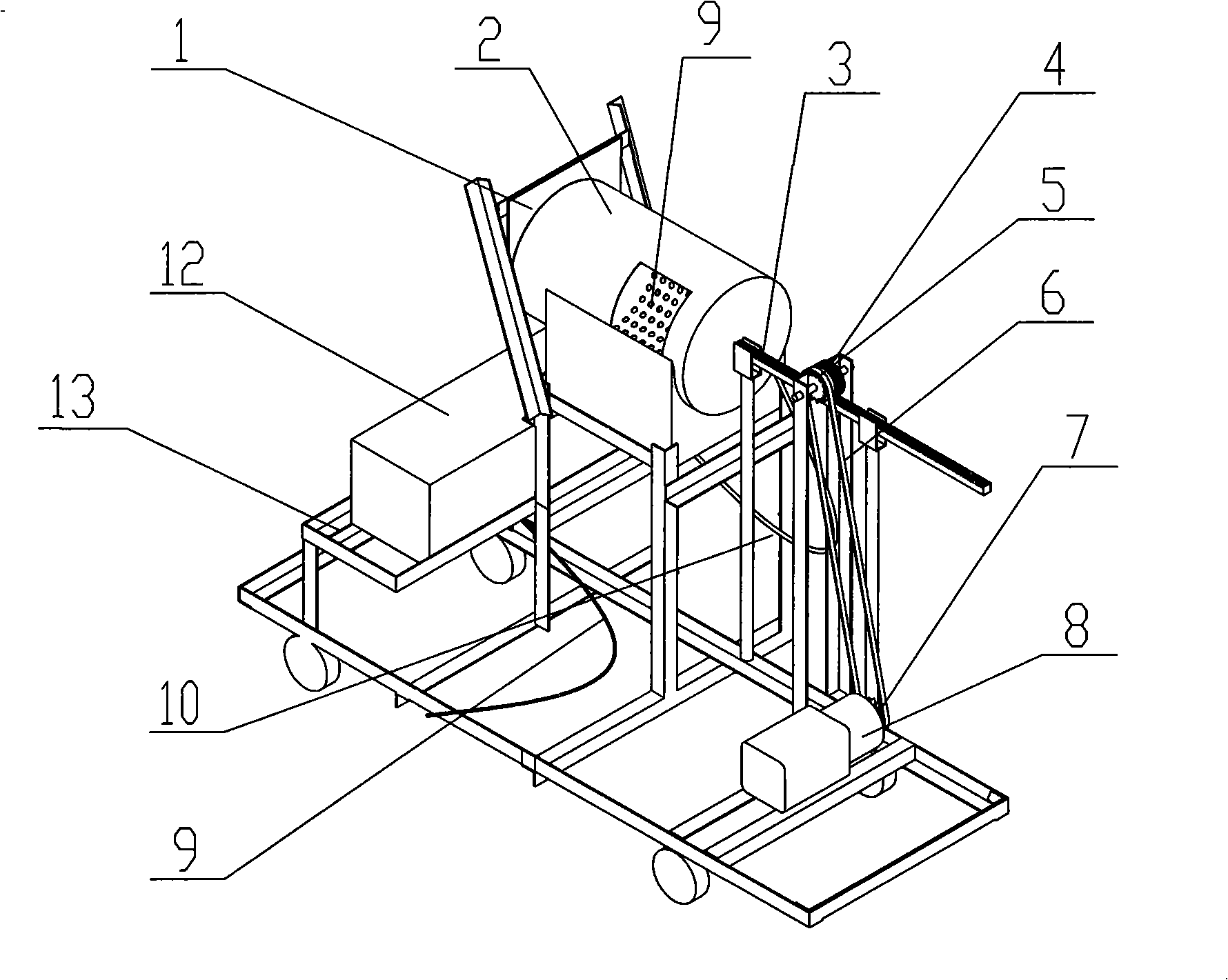

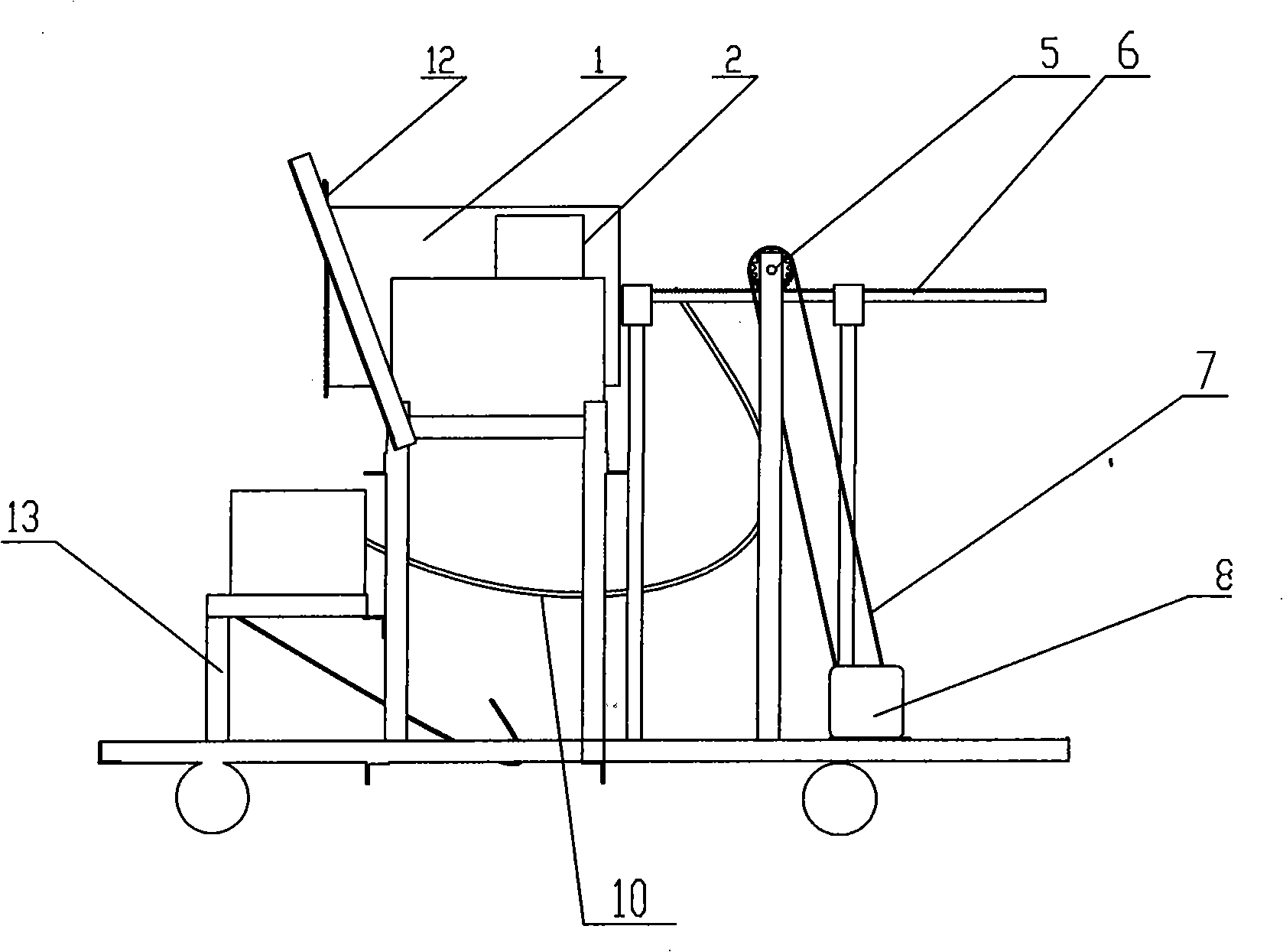

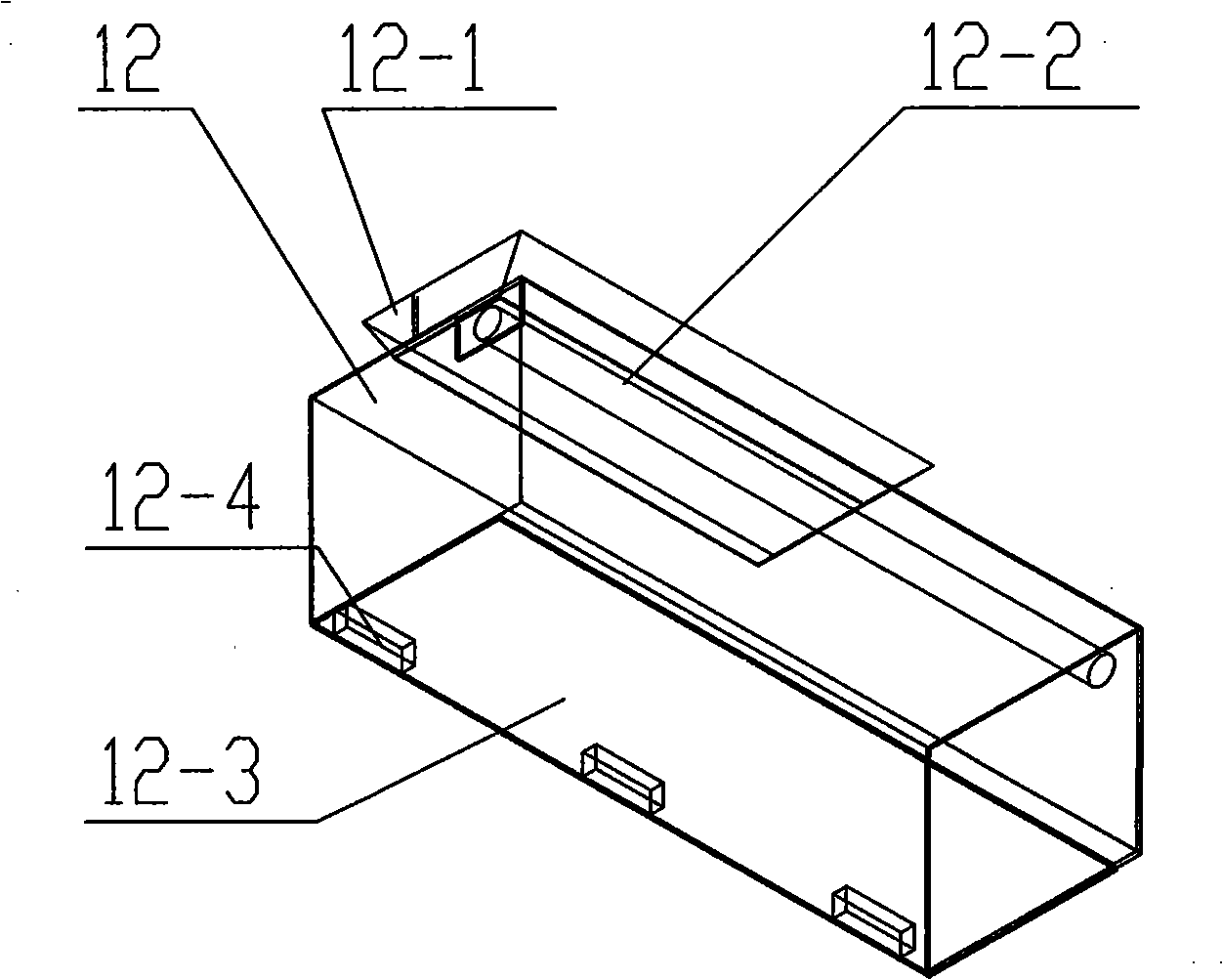

[0017] refer to Figure 1-3 : An integrated device for solid-liquid separation and disinfection of food waste, comprising a solid-liquid separation mechanism and a dry garbage disinfection mechanism, the solid-liquid separation mechanism includes a compression barrel 2, a piston, and a linear reciprocating mechanism, and the compression barrel 2 is provided There is a garbage inlet 2-1, the executive element of the linear reciprocating mechanism is pierced at one end of the compression barrel 2, and the front end of the actuator is connected to the slidable piston in the compression barrel 2, and the compression barrel 2 is provided with an outlet Liquid hole 9, the other end of the compression barrel 2 is provided with a garbage outlet, and an openable constant pressure door 1 is installed on the garbage outlet, and the constant pressure door 1 is connected to a spring wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com