Method for improving surface activity of aramid fiber

A technology of aramid fiber and surface activity, which is applied in fiber treatment, fiber type, textile and paper making, etc. It can solve the problems of many processing steps, harsh processing conditions, and complicated process, so as to improve the interface bonding strength and facilitate continuous processing , the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

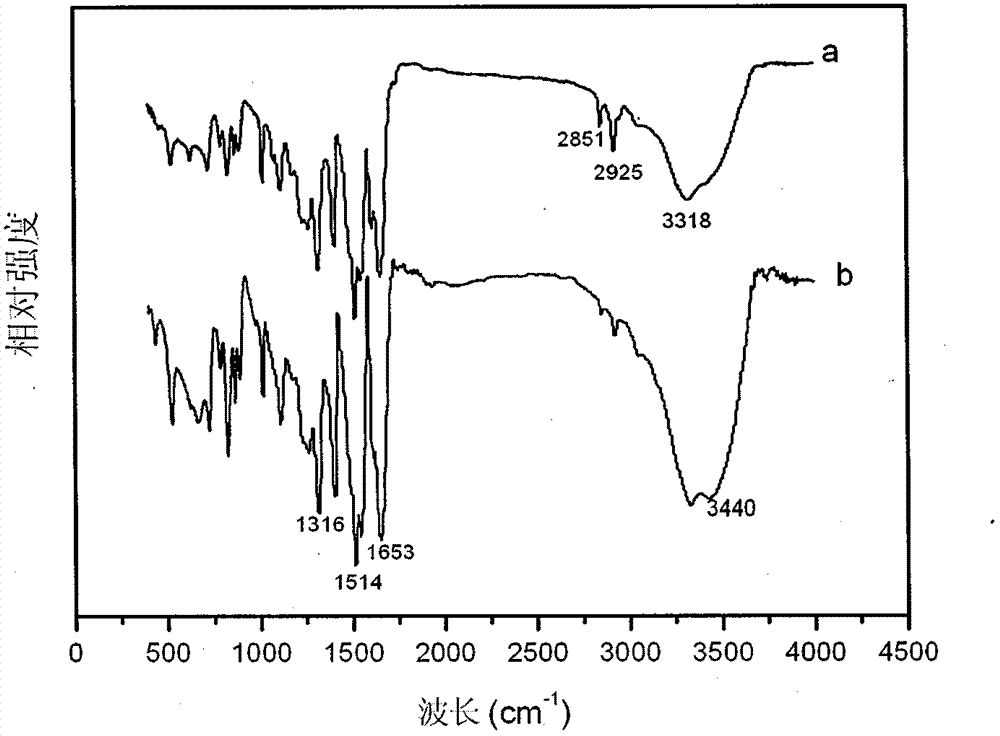

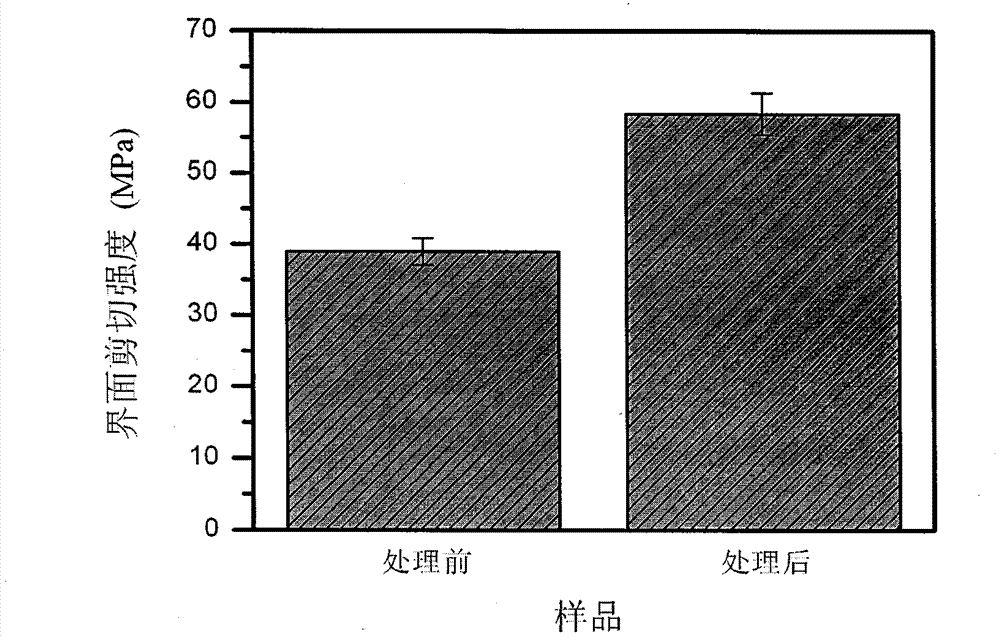

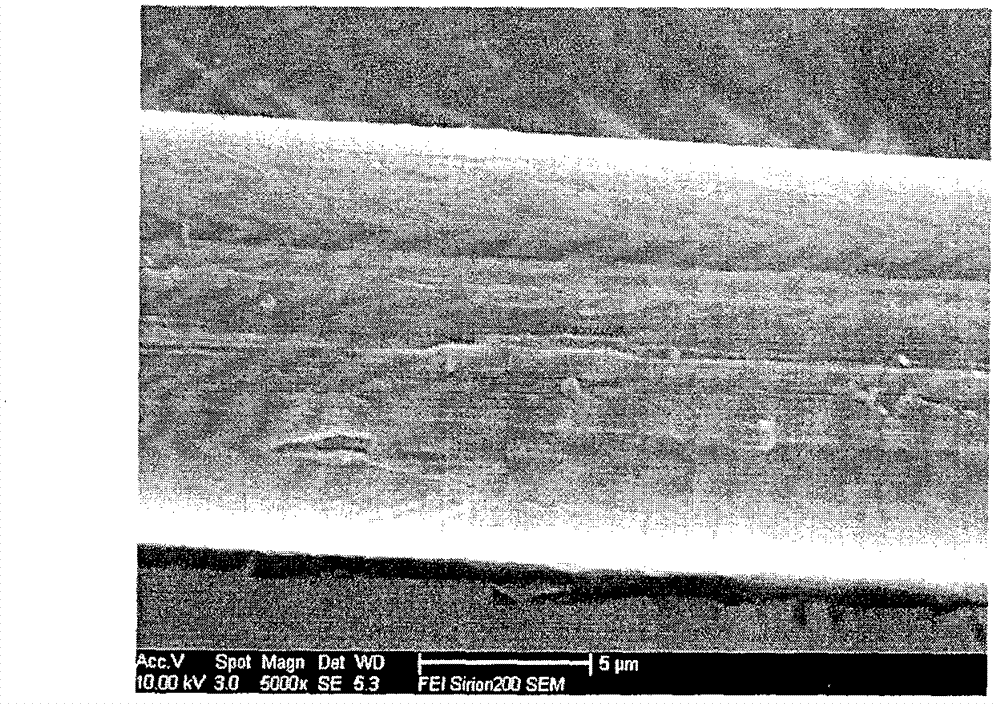

[0029] Embodiment 1 A kind of method that improves aramid fiber surface activity

[0030] Proceed as follows:

[0031] (1) Surface pretreatment of aramid fibers:

[0032] Immerse the aramid fibers in acetone and heat and boil for 1 hour, then immerse in absolute ethanol and heat and boil for 1 hour; then place the aramid fibers in deionized water for washing to remove the surface treatment agent during fiber processing, and the treatment is complete Finally, dry the aramid fiber in an electric heating constant temperature blast drying oven (the temperature is controlled between 100°C and 120°C, the same below) for 2 hours;

[0033] (2) Surface activation treatment of aramid fibers:

[0034] ① Prepare a hydrogen peroxide solution with a concentration of 40%;

[0035] ② Cut the pretreated aramid fiber into a sample of 20cm±2cm, place it in the hydrogen peroxide solution prepared above, and treat it at 40°C for 60min;

[0036] ③ Washing the above-mentioned activated aramid fi...

Embodiment 2

[0047] Embodiment 2 A kind of method that improves aramid fiber surface activity

[0048] Proceed as follows:

[0049] (1) Surface pretreatment of aramid fibers:

[0050] Immerse the aramid fibers in acetone and heat and boil for 1 hour, then immerse in absolute ethanol and heat and boil for 1 hour; then place the aramid fibers in deionized water for washing to remove the surface treatment agent during fiber processing, and the treatment is complete Finally, the aramid fiber was dried in an electric heating constant temperature blast drying oven for 1.5 hours;

[0051] (2) Surface activation treatment of aramid fibers:

[0052] ① Prepare a hydrogen peroxide solution with a concentration of 60%;

[0053] ②Cut the pretreated aramid fibers into 20cm±2cm samples, place them in the hydrogen peroxide solution prepared above, and treat them at 0°C for 90 minutes;

[0054] ③ Washing the above-mentioned activated aramid fiber with deionized water until the pH value of the washing s...

Embodiment 3

[0056] Embodiment 3 A kind of method that improves aramid fiber surface activity

[0057] Proceed as follows:

[0058] (1) Surface pretreatment of aramid fibers:

[0059] Immerse the aramid fibers in acetone and heat and boil for 1 hour, then immerse in absolute ethanol and heat and boil for 1 hour; then place the aramid fibers in deionized water for washing to remove the surface treatment agent during fiber processing, and the treatment is complete Finally, the aramid fiber was dried for 2.5 hours in an electric heating constant temperature blast drying oven;

[0060] (2) Surface activation treatment of aramid fibers:

[0061] ① Prepare a hydrogen peroxide solution with a concentration of 20%;

[0062] ② Cut the pretreated aramid fiber into a sample of 20cm±2cm, place it in the hydrogen peroxide solution prepared above, and treat it at 80°C for 30min;

[0063] ③ Washing the above-mentioned activated aramid fiber with deionized water until the pH value of the washing solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com