Preparation method of polyacrylate/nano silicon dioxide composite emulsion coating material

A technology of nano-silica and polyacrylate, which is applied in the direction of coating, etc., can solve problems such as difficulties, large specific surface area, and high surface energy, and achieve the effects of improving heat resistance, easy access to raw materials, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

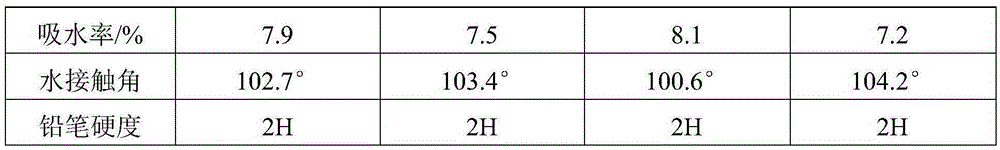

Examples

Embodiment 1

[0020] Preparation of modified nano silicon dioxide: add 42.0g orthosilicate ethyl ester and 66.0g dehydrated ethanol in the reactor, heat to 45 ℃, then add the mixture of 0.7g ammoniacal liquor, 8.0g ethanol and 14.0g distilled water, Continue to react at 45°C for 4h to obtain nano-silica alcohol sol, then continue to add 2O.Og silane coupling agent (KH-570), and continue to react at a constant temperature for 4h at 45°C to obtain surface-grafted KH-570 nano Silica sol.

[0021] Preparation of polyacrylate / nano-silica composite emulsion: add 35g of deionized water, 0.6g of sodium dodecylbenzenesulfonate, and 0.3g of nonylphenol polyoxyethylene ether into the reactor, stir for 30min, and then Add 4g of acrylic acid, 40g of butyl acrylate, 16g of methyl methacrylate, and 15g of modified nano-silica sol, and pre-emulsify for 30 minutes to obtain a pre-emulsion. Into the reactor, sequentially add 50g of deionized water, 1.4g of sodium dodecylbenzenesulfonate, 0.7g of nonylphenol...

Embodiment 2

[0024] Preparation of modified nano silicon dioxide: add 31.2g orthosilicate ethyl ester and 48.3g absolute ethanol in the reactor, be heated to 48 ℃, then add the mixture of 0.4g ammoniacal liquor, 6.0g ethanol and 12.0g distilled water, Continue to react at 48°C for 4h to obtain nano-silica alcohol sol, then continue to add 15.0g of silane coupling agent (KH-570), and continue to react at a constant temperature for 4h at 48°C to obtain surface-grafted KH-570 nano Silica sol.

[0025] Preparation of polyacrylate / nano-silica composite emulsion: add 40g of deionized water, 0.8g of sodium dodecylbenzenesulfonate, and 0.4g of nonylphenol polyoxyethylene ether into the reactor, stir for 45min, and then Add 5g of acrylic acid, 30g of butyl acrylate, 25g of methyl methacrylate, and 16.8g of modified nano-silica sol, and pre-emulsify for 45 minutes to obtain a pre-emulsion. Into the reactor, sequentially add 45g of deionized water, 1.8g of sodium dodecylbenzenesulfonate, 0.9g of non...

Embodiment 3

[0028] Preparation of modified nano silicon dioxide: add 37.5g orthosilicate ethyl ester and 58g dehydrated ethanol in the reactor, heat to 50 ℃, then add the mixture of 0.6g ammoniacal liquor, 7.0g ethanol and 16.0g distilled water, then Continue to react at 50°C for 4h to obtain nano-silica alcohol sol, then continue to add 18.0g of silane coupling agent (KH-570), and continue to react at a constant temperature for 4h at 50°C to obtain nanometer silica with surface grafted KH-570. Silica sol.

[0029] Preparation of polyacrylate / nano-silica composite emulsion: add 45g of deionized water, 0.4g of sodium dodecylbenzenesulfonate, and 0.2g of nonylphenol polyoxyethylene ether into the reactor, stir for 40min, and then Add 3g of acrylic acid, 25g of butyl acrylate, 22g of methyl methacrylate, and 10g of modified nano-silica sol, and pre-emulsify for 40 minutes to obtain a pre-emulsion. Into the reactor, sequentially add 40g of deionized water, 1.2g of sodium dodecylbenzenesulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com