High-specific surface area nanometer mesoporous silicon carbide hollow ball and preparation method thereof

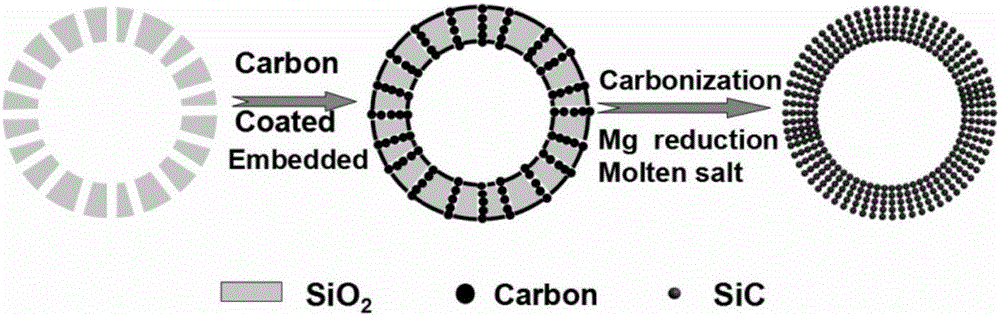

A mesoporous silicon carbide, high specific surface area technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem that the SiC hollow sphere structure cannot guarantee the integrity, the synthesis process is complex, synthesis temperature, Inability to mass-produce and other problems to achieve the effects of high integrity, low cost, and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 30mlC 2 h 5 OH in 100ml distilled water, add 0.1gCTAB as a pore-forming agent, stir in a water bath at 35°C for 30min; then add 2ml of NH to the above solution 3 ·H 2 O continue to stir rapidly; then add 1ml of TEOS drop by drop, and stir vigorously at 35°C for 24h; 2 h 5 OH and distilled water were washed three times.

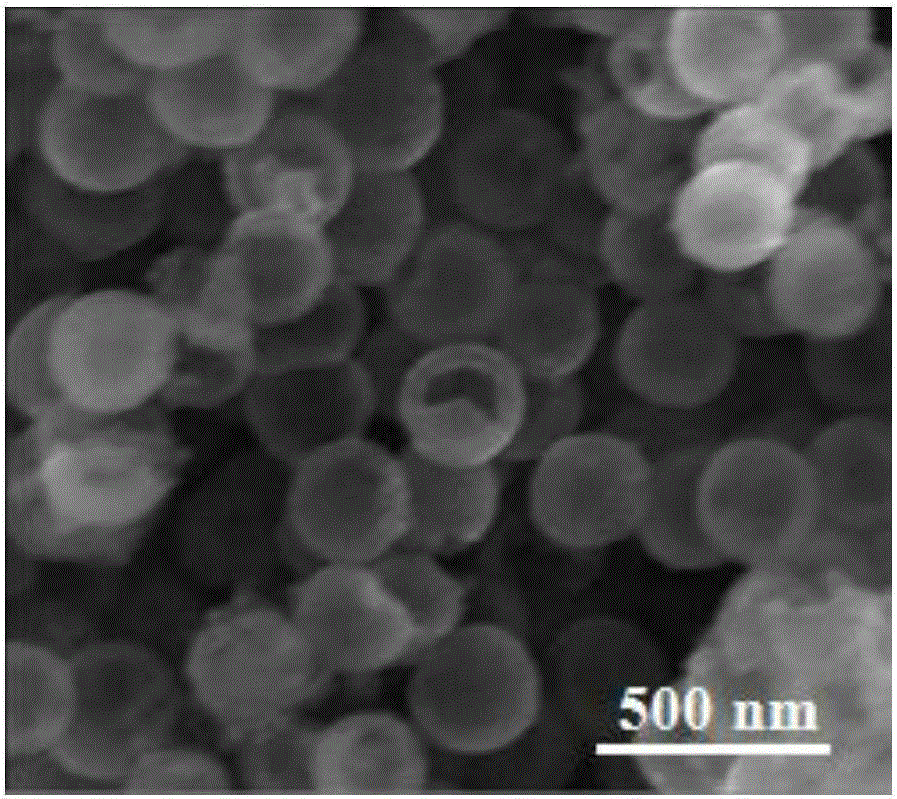

[0032] (2) Disperse the washed white sample in 160ml distilled water, place the dispersed solution in a constant temperature water tank and keep it warm at 20°C for 6 hours to prepare nano-SiO with uniform structure 2 hollow ball.

[0033] (3) by wet chemical method on SiO 2 The surface of the inner shell of the nano hollow sphere is coated with a layer of organic matter and the organic matter is embedded in the shell wall. The specific steps are: put 0.1g of SiO 2 The hollow spheres were ultrasonically dispersed in 100ml of distilled water, 0.1g of triblock copolymer was added, followed by 0.2g of Tris, stirred vigorously to clarify the ...

Embodiment 2

[0036] (1) Add 50mlC 2 h 5 OH in 250ml distilled water, add 0.5g CTAB as a pore-forming agent, stir in a water bath at 35°C for 30min; then add 3ml of NH to the above solution 3 ·H 2 O continue to stir rapidly; then add 2ml of TEOS drop by drop, and stir vigorously at 35°C for 24h; 2 h 5 OH and distilled water were washed three times.

[0037] (2) Disperse the washed white sample in 160ml distilled water, put the dispersed solution in a constant temperature water tank and keep it warm at 25°C for 12 hours to prepare nano-SiO with uniform structure 2 hollow ball.

[0038] (3) by wet chemical method on SiO 2 The surface of the inner shell of the nano hollow sphere is coated with a layer of organic matter and the organic matter is embedded in the shell wall. The specific steps are: put 0.5g of SiO 2 The hollow spheres were ultrasonically dispersed in 200ml of distilled water, 0.25g of triblock copolymer was added, followed by 0.5g of Tris, stirred vigorously to clarify the...

Embodiment 3

[0041] (1) Add 20mlC 2 h 5 OH in 250ml of distilled water, add 1gCTAB as a pore-forming agent, stir in a water bath at 35°C for 30min; then add 4ml of NH to the above solution 3 ·H 2 O continue to stir rapidly; then add 3ml of TEOS dropwise, and stir vigorously at 35°C for 24h; 2 h 5 OH and distilled water were washed three times.

[0042] (2) Disperse the washed white sample in 450ml distilled water, put the dispersed solution in a constant temperature water tank and keep it warm at 30°C for 18 hours to prepare nano-SiO with uniform structure 2 hollow ball.

[0043] (3) by wet chemical method on SiO 2 The surface of the inner shell of the nano hollow sphere is coated with a layer of organic matter and the organic matter is embedded in the shell wall. The specific steps are: put 1g of SiO 2 The hollow spheres were ultrasonically dispersed in 250ml of distilled water, 2g of triblock copolymer was added, followed by 2g of Tris, stirred vigorously to clarify the solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com