Crosslinking sodium hyaluronate gel and preparation method thereof

A technology for cross-linking hyaluronic acid and sodium hyaluronate, which is used in pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problem of inability to effectively increase the proportion of cross-linking modification, and achieves reducing the degree of suspension modification and improving cross-linking. The effect of joint modification and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The influence of time on degree of cross-linking in embodiment 1 traditional cross-linking process

[0043] 1. Add 1.0 g of sodium hyaluronate with a molecular weight of 2 million Daltons into 150 mL of 1% (w / w) NaOH solution, and stir at room temperature for 4 hours until completely dissolved.

[0044] 2. Take 0.2mL of 1,4-butanediol diglycidyl ether, dilute it with 50mL of distilled water and keep it for later use.

[0045] 3. Put the NaOH solution of sodium hyaluronate in a magnetic stirrer, add the diluted BDDE solution dropwise to the system under stirring at room temperature, and finish dropping in 10 minutes. After dropping, continue to react for a certain period of time. The reaction time is shown in the table 1.

[0046] 4. Add 0.005 mol / L hydrochloric acid solution to adjust to pH = 7.2, and balance for 2 hours under stirring, then add 500 mL of absolute ethanol, precipitate for 2 hours, and take out the massive solid.

[0047] After freeze-drying the obtain...

Embodiment 2

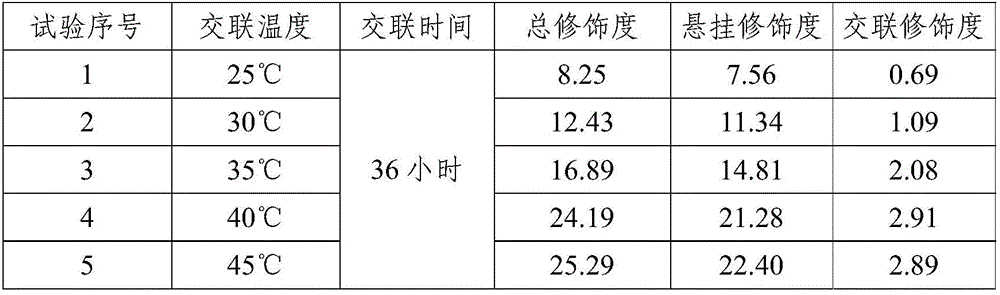

[0050] Influence of crosslinking temperature on degree of crosslinking in the traditional crosslinking process of embodiment 2

[0051] 1. Add 1.0 g of sodium hyaluronate with a molecular weight of 2 million Daltons into 150 mL of 1% (w / w) NaOH solution, and stir at room temperature for 4 hours until completely dissolved.

[0052] 2. Take 0.2mL of 1,4-butanediol diglycidyl ether, dilute it with 50mL of distilled water and keep it for later use.

[0053] 3. Put the NaOH solution of sodium hyaluronate in a magnetic stirrer, and add the BDDE solution dropwise to the system under stirring in the temperature range of 25-45°C. After 10 minutes, continue to react for 36 hours. .

[0054] 4. Add 0.005 mol / L hydrochloric acid solution to adjust to pH = 7.2, and balance for 2 hours under stirring, then add 500 mL of absolute ethanol, precipitate for 2 hours, and take out the massive solid.

[0055] After freeze-drying the obtained solid, the degree of cross-linking was tested, and the...

Embodiment 3

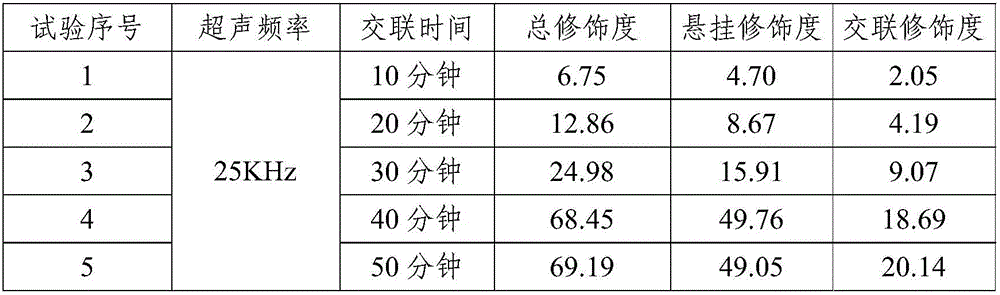

[0058] Influence of reaction time on degree of crosslinking in the ultrasonic crosslinking process of embodiment 3

[0059] 1. Add 1.0 g of sodium hyaluronate with a molecular weight of 2 million Daltons into 150 mL of 1% (w / w) NaOH solution, and stir at room temperature for 4 hours until completely dissolved.

[0060] 2. Take 0.2mL of 1,4-butanediol diglycidyl ether, dilute it with 50mL of distilled water and keep it for later use.

[0061] 3. Put the NaOH solution of sodium hyaluronate in an ultrasonic reactor with adjustable frequency, adjust the ultrasonic frequency to 25KHz, ultrasonicate at room temperature, and add the BDDE solution to the system dropwise, and finish dropping in 10 minutes. After dropping, continue to ultrasonicate React for 0 to 40 minutes, and observe the effect of reaction time on the degree of crosslinking (Table 3).

[0062] 4. Add 0.005 mol / L hydrochloric acid solution to adjust to pH = 7.2, and balance for 2 hours under stirring, then add 500 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com